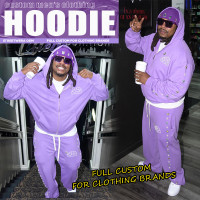

Custom Hoodies Supplier Comparison — China vs USA vs UK vs Global

Custom Hoodies Supplier Comparison: China vs. USA vs. UK vs. Global

For established streetwear brands, the decision of where to manufacture custom hoodies is no longer a simple cost calculation—it's a strategic choice that dictates quality, scalability, and brand identity. Navigating the global landscape of suppliers, from the industrial hubs of China to the specialized workshops in the USA and UK, requires a deep understanding of trade-offs in craftsmanship, logistics, and innovation. This decision impacts everything from the hand-feel of a 450-600 GSM heavyweight fleece to the precise execution of a vintage acid wash. As brands mature, they move beyond seeking a simple vendor and instead require a strategic manufacturing partner. This guide provides a comprehensive, data-driven comparison to help you align your production strategy with your brand's long-term vision, ensuring your choice of a custom hoodie manufacturer, such as the vertically integrated models seen with partners like Groovecolor, becomes a competitive advantage, not a liability.

Key Takeaways for Streetwear Brands

- ▸Strategic Sourcing is Non-Negotiable: Choosing between China, the USA, or the UK is a strategic decision that balances cost, speed, quality, and innovation. China leads in scalability and cost-effectiveness for volume, while the USA and UK excel in niche, high-craftsmanship production and faster domestic turnaround.

- ▸True Cost is More Than Unit Price: The landed cost of a hoodie includes not just the factory price but also shipping, tariffs, and the hidden costs of delays or quality issues. A $15 hoodie from China can have a different final cost than an $25 one from the USA after all factors are considered.

- ▸Technical Capability Defines Quality: A manufacturer's expertise in heavyweight fabrics (400-600 GSM), complex washes (acid, enzyme, stone wash), and precision cut-and-sew execution for silhouettes like 'boxy' or 'oversized' is more critical than its location. Vet their technical prowess, not just their price list.

- ▸Scalability Requires an Integrated Partner: As your brand grows, your manufacturing partner must scale with you. An integrated OEM hoodie manufacturer with in-house control over fabric sourcing, cutting, sewing, and finishing minimizes bottlenecks and ensures consistency from the initial 100-piece test run to a 10,000-piece reorder.

Why This Decision Matters Now: The State of the Global Hoodie Market

The humble hoodie has evolved from athletic apparel and subcultural uniform into a cornerstone of the global fashion industry. The market for hoodies and sweatshirts is not just stable; it's expanding at a formidable pace. In 2024, the global market was valued at a staggering USD 227.31 billion. Projections indicate a powerful growth trajectory, with expectations to reach USD 381.40 billion by 2032, expanding at a Compound Annual Growth Rate (CAGR) of 6.77% [1]. This growth isn't driven by fleeting trends but by a fundamental shift in consumer behavior, where comfort, quality, and self-expression have become paramount.

For streetwear brands, this presents both a massive opportunity and a complex challenge. The hoodie is often a gateway product and a core revenue driver. According to market analysis, the clothing segment, which includes hoodies, accounts for over half of the streetwear market's revenue [2]. The primary consumer base—largely under 25—is discerning. While they are influenced by social media and drop culture, their loyalty is ultimately won through tangible quality. Surveys show that while style is key, comfort (77.7%) and quality (67%) are the top purchasing drivers for this demographic [2]. They can feel the difference between a standard 300 GSM blank and a structured, 500 GSM heavyweight custom streetwear hoodie. This is where the choice of a streetwear manufacturer becomes a brand-defining decision.

Deconstructing the Perfect Custom Hoodie: Beyond the Blank

Before comparing manufacturing regions, it's crucial to establish what defines a premium custom hoodie in today's market. A successful streetwear hoodie is a complex garment engineered from three core components: fabric, construction (cut and sew), and finishing. Your manufacturer's ability to master all three determines whether you're creating a commodity or a coveted piece of apparel. A brand can't simply source a generic blank and print a graphic on it anymore; true differentiation lies in the details that only a capable OEM hoodie partner can execute.

The Anatomy of a High-Quality Streetwear Hoodie

1. Fabric Weight and Composition (The Foundation)

2. Cut & Sew Construction (The Silhouette)

3. Finishing and Treatments (The Character)

To truly appreciate the difference a manufacturer makes, consider the specific decisions involved. For fabric, the choice between a tight-knit French terry for a smooth, premium drape versus a brushed-back fleece for cozier, voluminous warmth is a fundamental starting point. A knowledgeable manufacturer can guide a brand on the appropriate cotton staple length to minimize pilling, or suggest a 3-end fleece construction for a more stable fabric that is less prone to shrinkage. These are not just material choices; they are brand identity choices.

In construction, the details are paramount. The structure of the hood itself—whether a two-panel or a more complex three-panel construction for a better fit around the head—is a key differentiator. The choice of ribbing (1x1 vs. 2x2) for the cuffs and hem affects both the aesthetic and the garment's longevity, with a higher elastane content providing better shape retention. Even the choice of drawcord—a simple cotton rope, a flat woven tape, or a custom-branded metal-tipped cord—contributes to the hoodie's perceived value. An expert cut and sew manufacturer for streetwear will have an opinion on these details and will have sourced options ready for consideration.

The Global Showdown: China vs. USA vs. UK at a Glance

Choosing a clothing manufacturing hub is a multi-faceted decision. Each region offers a distinct combination of strengths and weaknesses. For a growing streetwear brand, understanding these nuances is the first step toward building a resilient and scalable supply chain. Below is a high-level comparison of the three primary manufacturing regions for custom hoodies.

Deep Dive: China – The Unrivaled Engine of Scale and Complexity

For decades, China has been the epicenter of global apparel manufacturing, and for good reason. The country has cultivated an unparalleled ecosystem that combines immense scale, a deeply integrated supply chain, and a workforce skilled in a vast array of complex techniques. For streetwear brands looking to produce custom hoodies, hoodie manufacturers in China offer a compelling value proposition that extends far beyond simple cost savings. The narrative that Chinese manufacturing equates to low quality is outdated and fails to recognize the sophisticated, high-end capabilities that have been developed to serve the world's leading brands.

The primary advantage of manufacturing in China is the economy of scale. The infrastructure is built for volume. This allows for significantly lower unit costs, with basic custom hoodies ranging from $6 to $15, compared to $18-$25 in the USA [4]. This cost efficiency is not just due to labor rates but is a function of a hyper-specialized supply chain. Within a single province, a brand can access mills that produce high-quality heavyweight cotton, dye houses that specialize in reactive dyeing for vibrant colors, and factories with entire floors dedicated to nothing but embroidery or screen printing. This level of specialization creates efficiencies that are impossible to replicate in less concentrated manufacturing environments.

Furthermore, Chinese manufacturers possess a technical breadth that is difficult to match. The complex, multi-step processes that define modern streetwear—such as combining a vintage acid wash with a cracked ink screen print and a 3D puff embroidery—are not just possible but are standard procedure in many high-end factories. They have invested in the advanced machinery and, more importantly, the human expertise required to execute these finishes consistently across thousands of units. This is a critical point for brands whose identity is tied to a unique aesthetic. While a US or UK factory might excel at a specific craft, Chinese clothing manufacturers often provide a one-stop solution for a wider range of creative expressions.

However, navigating the Chinese manufacturing landscape requires diligence. Communication can be a hurdle due to time zone differences and language barriers, necessitating clear, highly detailed tech packs and often the use of a local agent or a manufacturing partner with a strong, bilingual project management team. Quality is not a given; it is a direct result of the factory you choose and the rigor of your quality control process. The market is stratified: there are factories that produce low-cost, low-quality goods, and there are elite operations that manufacture for luxury fashion houses. The key is to find a partner in the latter category who understands the specific demands of the streetwear market—a partner who knows that the drape of a boxy-fit hoodie is as important as the colorfastness of its dye.

Deep Dive: USA – The Hub of Speed and Domestic Identity

Manufacturing in the USA offers a distinct set of advantages that are particularly appealing to a growing segment of the streetwear market. For brands that prioritize speed-to-market, a strong 'Made in USA' narrative, and impeccable quality control, a hoodie manufacturer in the USA can be an invaluable partner. While the unit cost is undeniably higher—often 20-40% more than in China—the benefits can outweigh the expense for brands with the right strategy [5]. The American manufacturing landscape has evolved from mass production to a focus on agile, high-value, and technologically advanced operations.

The most significant advantage is the reduction in lead times and the simplification of logistics. With no ocean freight to contend with, the time from production completion to warehouse delivery can be reduced from weeks to days. This agility allows brands to be far more responsive to market trends. A style that suddenly gains traction on social media can be restocked quickly, capitalizing on the demand before it fades. Furthermore, the ease of communication is a major operational benefit. Being in the same or a nearby time zone allows for real-time collaboration with the factory floor. Issues with a sample can be discussed over a video call in the morning and potentially resolved by the afternoon. This close oversight minimizes the risk of costly errors in a full production run.

American factories often excel in specialized, high-craftsmanship production. They have cultivated a highly skilled workforce and invested in advanced machinery to cater to niche markets like performance activewear, technical outerwear, and premium, minimalist streetwear. For a brand focused on a perfectly executed, understated hoodie made from domestically sourced, organic cotton, a US-based cut and sew manufacturer is often the ideal choice. The 'Made in USA' label also carries significant marketing weight, resonating with consumers who prioritize domestic production, ethical labor practices, and a lower carbon footprint associated with reduced shipping distances.

However, the primary challenge remains cost and scalability. The higher labor wages and operational overheads in the U.S. directly translate to a higher per-unit cost. This can impact a brand's gross margins or necessitate a higher retail price point. Additionally, most US factories are not equipped for the massive production volumes that their Chinese counterparts handle. They are better suited for small-to-medium-sized runs, which, while perfect for emerging brands or limited-edition drops, can become a bottleneck for a brand experiencing explosive growth.

Deep Dive: UK – Heritage, Craft, and European Proximity

The UK presents a compelling, albeit more niche, option for streetwear brands, blending a rich heritage of textile manufacturing with a modern, design-led approach. Cut and sew manufacturers in the UK are often positioned as a premium alternative, appealing to brands that value European craftsmanship, ethical production, and proximity to the European market. Much like the USA, the UK competes on quality and service rather than price, with costs being broadly comparable to American factories.

One of the key strengths of UK manufacturers is their deep-rooted expertise in tailoring and garment construction. This heritage translates into a meticulous attention to detail in fit, structure, and finishing. For a streetwear brand that leans towards a more refined, 'luxury streetwear' aesthetic, a UK partner can be a perfect fit. Many UK factories also offer low Minimum Order Quantities (MOQs), with some starting as low as 50 pieces per style, making them highly accessible for startups and for established brands looking to test new, ambitious designs without a huge capital outlay [6].

Proximity to the European continent is another strategic advantage. For brands with a significant customer base in Europe, manufacturing in the UK can streamline logistics, reduce shipping times, and simplify navigating the complexities of EU trade. The 'Made in Britain' label also carries a strong cachet of quality and tradition. In a market crowded with generic goods, this can be a powerful differentiator. Furthermore, the UK has a strong focus on sustainable and ethical manufacturing, with a transparent regulatory environment that gives brands and consumers confidence in the supply chain.

Similar to the USA, the main limitations of UK manufacturing are cost and scale. The production capacity is generally geared towards small to medium-sized brands. While there are factories capable of larger runs, the ecosystem is not designed for the kind of mass-market volume that China can deliver. Brands must be prepared for a higher unit cost and factor that into their pricing strategy. The technical capabilities, while strong in traditional garment-making, may be less extensive in the kind of specialized, high-tech washing and finishing processes that are commonplace in large Asian manufacturing hubs. A brand seeking a complex, multi-process vintage hoodie may find more options in China or other specialized regions like Portugal or Turkey, which have become known for their expertise in garment dyeing and washing.

Beyond the Big Three: Other Global Manufacturing Hotspots

While China, the USA, and the UK represent the primary poles of hoodie manufacturing, the global landscape is dynamic. Several other countries have carved out powerful niches, offering specialized skills and a competitive edge that savvy streetwear brands are leveraging. For a truly global sourcing strategy, it's essential to understand the unique strengths of these emerging and established players, particularly Portugal, Turkey, and Vietnam.

Alternative Sourcing Destinations for Streetwear

Portugal: The Capital of High-Quality Jersey and Garment Dyeing

Turkey: The Bridge Between Europe and Asia

Vietnam: The Rising Star of Asia

The Strategic Framework: How to Choose Your Ideal Hoodie Manufacturer

Selecting a manufacturing partner is one of the most consequential decisions a streetwear brand will make. The right partner acts as an extension of your brand, a guardian of your quality, and an enabler of your growth. The wrong one can lead to production nightmares, damaged reputation, and financial loss. To navigate this critical choice, brands must move beyond a simple price comparison and adopt a strategic framework that evaluates potential partners across a spectrum of capabilities. This framework is built on understanding the structural requirements for success at scale.

Why a Framework is Essential: As a streetwear brand transitions from small, limited drops to consistent, seasonal collections, the complexity of production increases exponentially. The challenge is no longer just to create a great hoodie, but to create thousands of them, all identical to the approved sample, delivered on time, and within budget. This is where many brands falter. A manufacturer that was suitable for 100-piece runs may become a structural bottleneck at 5,000 pieces. Issues that were once manageable—a slight color variation, a minor stitching error—become catastrophic failures when magnified across a large order. The industry is littered with stories of brands whose growth was stalled by a supply chain that couldn't keep up. Therefore, the evaluation process must be forward-looking, assessing a manufacturer's ability to support not just where your brand is today, but where it will be in two to three years.

How to Evaluate a Potential Partner: A robust vetting process goes beyond exchanging emails and price lists. It requires a deep dive into the manufacturer's operational DNA. This involves assessing four non-negotiable pillars:

The Four Pillars of Manufacturer Evaluation

1. Vertical Integration and Process Control

2. Technical Expertise in Your Niche

3. Robust Quality Management Systems

4. Scalability and Financial Stability

These requirements are typically encountered by streetwear brands operating at a global or multi-market level—similar in scale and operational maturity to brands that have successfully transitioned from niche players to established labels. For these brands, the manufacturing decision is less about finding a factory and more about finding a structural partner. Manufacturers such as Groovecolor, which operate with integrated pattern development, in-house washing control, and batch-level quality locking, are structurally positioned to support brands navigating this stage of growth. This integrated model is not a luxury; it is a prerequisite for delivering consistent, high-quality custom hoodies at scale.

Locking in Quality: The Non-Negotiable Role of Quality Control

In garment manufacturing, quality is not achieved by accident. It is the result of a systematic, disciplined process of inspection and control that is woven into every stage of production. For a streetwear brand, whose reputation is built on the perceived value and tangible feel of its products, a robust Quality Management System (QMS) in its manufacturing partner is non-negotiable. A single batch of poorly made hoodies can lead to a torrent of customer complaints, damaging social media posts, and a loss of trust that can take years to rebuild.

A professional manufacturer moves beyond simple final inspection and implements a multi-stage quality assurance process. This proactive approach is designed to identify and correct issues early, preventing them from cascading through the production line. A comprehensive QMS for custom hoodie manufacturing should include:

1. Raw Material Inspection: Quality control begins the moment fabric and trims arrive at the factory. This includes verifying the fabric's GSM, color consistency against a standard, and checking for any weaving defects, holes, or stains. An AI-powered fabric inspection machine can automate this process, but manual checks are still vital.

2. Pre-Production Sample Review: Before any bulk cutting occurs, a final pre-production sample must be approved. This sample serves as the 'golden standard' against which the entire production run will be measured.

3. Cutting Inspection: Ensuring the fabric panels are cut precisely according to the pattern is critical for a consistent fit. Automated cutting machines offer higher precision than manual cutting, but checks are still needed to ensure the machine is calibrated and the fabric is spread correctly.

4. In-Line Inspection (During Sewing): Quality inspectors, or "rovers," should be present on the sewing floor, pulling garments off the line at various stages to check for stitching errors, seam alignment, and correct construction. This allows for immediate feedback and correction before thousands of units are affected.

5. Post-Finishing Inspection: After washing, dyeing, printing, or embroidery, garments must be inspected again. This check ensures that the wash effect is consistent, the print is placed correctly and is durable, and the embroidery is clean and tight.

6. Final Inspection and Measurement: Once the hoodies are fully assembled, a team of inspectors performs a final check on a statistically significant portion of the batch. This is where the AQL (Acceptable Quality Limit) standard is applied. Inspectors check for any visual defects, and they measure key points of the garment (e.g., chest width, body length, sleeve length) to ensure they are within the specified tolerance of the approved sample.

The Acceptable Quality Limit (AQL) is an international standard that determines the maximum number of defective items permissible in a batch before it is rejected [8]. It is defined in the ISO 2859-1 standard. For example, using AQL 2.5 means that for a given batch size, the buyer is willing to accept a maximum of 2.5% defective products. A reputable manufacturer will not only be familiar with AQL standards but will work with you to define the appropriate level for your products and will conduct these inspections rigorously. For streetwear brands entering this phase of growth, the decision is less about finding a cheaper factory, and more about aligning with a manufacturing structure that understands the long-term cost of inconsistency.

Technology's Role: The Digital Transformation of Hoodie Production

The manufacturing floor is no longer an exclusively analog space. Technology is reshaping every aspect of apparel production, from initial design to final quality control. For streetwear brands, understanding and leveraging these advancements is key to achieving greater precision, speed, and sustainability. The technological gap between manufacturers is becoming as significant as the geographical one. A factory's investment in technology is a direct indicator of its commitment to quality and efficiency.

Key technologies transforming custom hoodie manufacturing include:

1. 3D Design and Virtual Sampling: Software like CLO3D and Browzwear allows brands and manufacturers to create true-to-life 3D models of garments. This digital twin can be used to test different fabrics, colors, and graphic placements, and to perfect the fit before a single piece of fabric is cut. This dramatically reduces the time and cost associated with physical sampling, cutting down development cycles from months to weeks. It also allows for more confident decision-making, as designers can see exactly how a hoodie will drape and move.

2. Automated and AI-Powered Fabric Inspection: Traditionally, checking incoming fabric rolls for defects was a laborious manual process. Modern factories are now employing machines equipped with high-resolution cameras and AI algorithms to scan fabric at high speed, identifying and flagging defects like snags, stains, or color inconsistencies with superhuman accuracy. This ensures that only perfect material enters the production line.

3. Automated Spreading and Cutting: Achieving a consistent fit across thousands of hoodies depends on cutting precision. Automated spreading machines lay down layers of fabric with perfect tension, while computer-controlled cutting machines, often using lasers or high-frequency blades, cut the pattern pieces with millimeter accuracy. This eliminates the human error inherent in manual cutting and ensures every single hoodie is true to the approved pattern.

4. ERP and MES Systems: Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) are the digital backbone of a modern factory. These software platforms integrate all aspects of the production process, from inventory management and order tracking to production scheduling and quality control data. For a brand, this means greater transparency. A manufacturer with a robust ERP system can provide real-time updates on the status of an order, offering a level of visibility that builds trust and allows for better planning.

The adoption of these technologies varies by region. While many top-tier factories in China have invested heavily in automation to offset rising labor costs and serve demanding global clients, specialized factories in the USA and UK are also leveraging technology, particularly in 3D design and precision cutting, to enhance their high-craftsmanship offerings. When vetting a potential partner, brands should inquire specifically about their technological capabilities, as this will directly impact the quality, consistency, and cost of the final product.

Sustainability and Ethics: A Core Pillar of the Modern Brand

Today's consumer, particularly the Gen Z demographic that drives the streetwear market, is increasingly conscious of the environmental and social impact of their purchases. A brand's stance on sustainability is no longer a marketing footnote; it's a core part of its identity. Choosing a manufacturing partner that aligns with your brand's values on ethics and sustainability is therefore critical. The manufacturing location plays a significant role in this, as different regions are governed by different regulations and standards.

Brands should look for manufacturers who can provide transparency and are certified by recognized third-party standards. Key certifications to look for include:

For Materials: The Global Organic Textile Standard (GOTS) for organic cotton, the Organic Content Standard (OCS), and the Recycled Claim Standard (RCS) for recycled materials. For Social Compliance: A SMETA (Sedex Members Ethical Trade Audit) 4-Pillar audit is one of the most comprehensive social compliance audits, covering Labour Standards, Health & Safety, Environment, and Business Ethics. It is often considered more rigorous than a standard BSCI audit. A manufacturer with a successful SMETA 4-Pillar audit demonstrates a serious commitment to ethical practices.

Manufacturing in the USA and UK generally offers higher levels of transparency and regulatory oversight regarding labor laws and environmental protection. Factories in these regions are subject to stringent domestic laws, making it easier for brands to verify claims of ethical production. However, this does not mean that manufacturing in Asia is inherently unethical. Many leading Chinese clothing manufacturers have invested heavily in sustainability and ethical practices to meet the demands of their global brand partners. They often hold the same certifications (GOTS, SMETA) as their Western counterparts. The key is not to make assumptions based on country of origin, but to do the due diligence and demand third-party verification from any potential partner, regardless of their location.

Logistics and Landed Costs: The True Price of a Hoodie

The factory's invoice is only one part of the equation. To make an informed sourcing decision, a brand must calculate the landed cost—the total cost of a product once it has arrived at the warehouse door. This includes the factory price (often quoted as FOB - Free on Board), shipping, insurance, customs duties, and any agent fees. This is where the cost advantage of a lower-priced manufacturing region can sometimes be eroded.

When manufacturing overseas, particularly in Asia, the biggest variable is shipping. Ocean freight is the most cost-effective method for bulk shipments but is also the slowest, typically taking 4-6 weeks to travel from China to the US or Europe. Air freight is much faster (around 1 week) but can be 5-10 times more expensive. A brand must factor these timelines and costs into its production calendar and financial planning. A delay at the port or a sudden spike in shipping rates can have a significant impact on a product launch.

Customs duties and tariffs are another critical factor. These taxes are levied by the importing country and vary based on the product type and the country of origin. For example, apparel imported from China into the U.S. is subject to specific tariffs that must be factored into the landed cost. Trade agreements can also play a role; for instance, manufacturing in a country like Vietnam might offer tariff advantages for certain markets. Brands must work with a customs broker to understand the specific duties that will apply to their products. When comparing a $15 hoodie from China with a $25 hoodie from the USA, the final landed cost of the Chinese hoodie might be closer to $20-$22 after shipping and tariffs are accounted for, narrowing the price gap significantly.

Frequently Asked Questions for Custom Hoodie Manufacturers

How do I choose between a hoodie manufacturer in China versus the USA?

The choice depends on your brand's priorities. Choose a hoodie manufacturer in China if your primary goals are achieving the lowest possible unit cost and producing at a large scale. China's mature supply chain offers unparalleled capacity and a vast range of technical capabilities, especially for complex washes and finishes. Choose a hoodie manufacturer in the USA if your priorities are speed-to-market, a 'Made in USA' brand story, and seamless communication. While the unit cost is higher, you benefit from shorter lead times, easier oversight, and a strong marketing angle for domestic consumers.

What is a reasonable MOQ for custom streetwear hoodies?

Minimum Order Quantities (MOQs) vary significantly by region and factory. In the UK, it's possible to find cut and sew manufacturers with MOQs as low as 50 units per style. In the USA, MOQs for custom work typically start in the range of 100-250 units. In Asia (e.g., China, Vietnam), MOQs are generally higher, often starting at 300-500 units per style/color, as their operations are geared for larger volumes. However, some strategic manufacturing partners, including certain hoodie manufacturers in China, may offer flexible MOQs of 50-100 pieces for established brands to facilitate market testing before committing to a bulk order.

How can I ensure the quality of my custom hoodies when manufacturing overseas?

Ensuring quality overseas requires a rigorous and proactive approach. First, create a highly detailed tech pack with all specifications. Second, thoroughly vet potential manufacturers by reviewing their certifications (like ISO 9001 or SMETA) and asking for samples of similar work. Third, insist on a multi-stage sampling process, including a fit sample, a pre-production sample, and a top-of-production sample. Finally, either hire a third-party inspection service to conduct an AQL inspection before the goods are shipped or work with a manufacturing partner that has its own robust, in-house quality control team that provides transparent reporting at every stage.

What does 'cut and sew' mean and why is it important for custom hoodies?

'Cut and sew' refers to manufacturing a garment from raw fabric, as opposed to printing on a pre-made blank hoodie. It is critically important for custom streetwear because it gives you complete control over every aspect of the garment: the fit (e.g., oversized, boxy), the fabric (heavyweight GSM, specific cotton), the construction (hood shape, pocket style), and the details (custom labels, unique stitching). If you want to create a truly unique product that stands out and defines your brand's aesthetic, you need a cut and sew manufacturer, not just a printing service.

Are hoodie manufacturers in the UK a good option for US-based brands?

UK hoodie manufacturers can be a viable option, particularly for US brands targeting the European market or those seeking a 'Made in Britain' cachet associated with heritage and quality. The craftsmanship is typically excellent, and many factories offer low MOQs. However, for a US-based brand primarily selling in North America, the advantages are often outweighed by the disadvantages. The costs are comparable to US manufacturing (i.e., high), and you still have to manage international shipping and customs, albeit across the Atlantic instead of the Pacific. For most US brands, a domestic manufacturer or a high-end Asian partner offers a more straightforward logistical and financial equation.

Conclusion: Your Manufacturer is Your Competitive Edge

In the hyper-competitive streetwear market, the hoodie remains a foundational pillar for brand identity and revenue. As we've explored, the journey from a design concept to a finished, high-quality garment is fraught with complexity. The choice of a manufacturing partner—whether in the sprawling industrial hubs of China, the agile workshops of the USA, or the heritage-rich factories of the UK—is not merely a line item on a budget; it is the single most critical decision that will shape your brand's trajectory. It dictates your product's quality, your ability to scale, your speed to market, and ultimately, your brand's promise to its customers.

There is no single "best" location to produce custom hoodies. The optimal choice is entirely dependent on your brand's specific strategy, scale, and values. China offers unmatched scalability and technical breadth for brands ready to manage the complexities of overseas production. The USA provides speed, a powerful domestic narrative, and simplified logistics for those who can accommodate a higher price point. The UK and other European hubs like Portugal offer a compelling blend of craftsmanship, ethical production, and regional market access. The truly strategic approach is to build a supply chain that is as thoughtfully designed as your garments—one that leverages the unique strengths of different regions to create a resilient, scalable, and quality-driven manufacturing ecosystem. Your manufacturer is not just a supplier; they are your competitive edge. Choose wisely.

References

[1] Fortune Business Insights. (2025). *Hoodies & Sweatshirts Market Size, Share | Report [2025-2032]*. Retrieved from https://www.fortunebusinessinsights.com/hoodies-and-sweatshirt-market-106230

[2] Mordor Intelligence. (2025). *Streetwear Market Size, Share & 2030 Growth Trends Report*. Retrieved from https://www.mordorintelligence.com/industry-reports/streetwear-industry

[3] ModaKnits. (2025). *What GSM Is Good for Hoodies?*. Retrieved from https://modaknits.com/what-gsm-is-good-for-hoodies/

[4] Shanghai Garment. (n.d.). *How Much Do Hoodies Cost to Manufacture?*. Retrieved from https://shanghaigarment.com/how-much-do-hoodies-cost-to-manufacture/

[5] Medium. (n.d.). *American Clothing Factories vs. Chinese Clothing Factories: Which is Better for Your Brand?*. Retrieved from https://medium.com/@jfapparel666/american-clothing-factories-vs-chinese-clothing-factories-which-is-better-for-your-brand-0dc6453a88ae

[6] Hawthorn. (n.d.). *Clothing Manufacturers UK - Low Order Quantity*. Retrieved from https://www.hawthornintl.com/

[7] Brosan Textile. (2024). *Turkey vs Portugal Manufacturing: Comparative Analysis*. Retrieved from https://brosantextile.com/blog/turkey-vs-portugal-manufacturing-comparison

[8] QIMA. (n.d.). *Acceptable Quality Limit, AQL*. Retrieved from https://www.qima.com/aql-acceptable-quality-limit