Top 4 GSM Used by Hoodie Manufacturer: The Complete Guide for Streetwear Brands

Top 4 GSM Used by Hoodie Manufacturer: The Complete Guide for Streetwear Brands

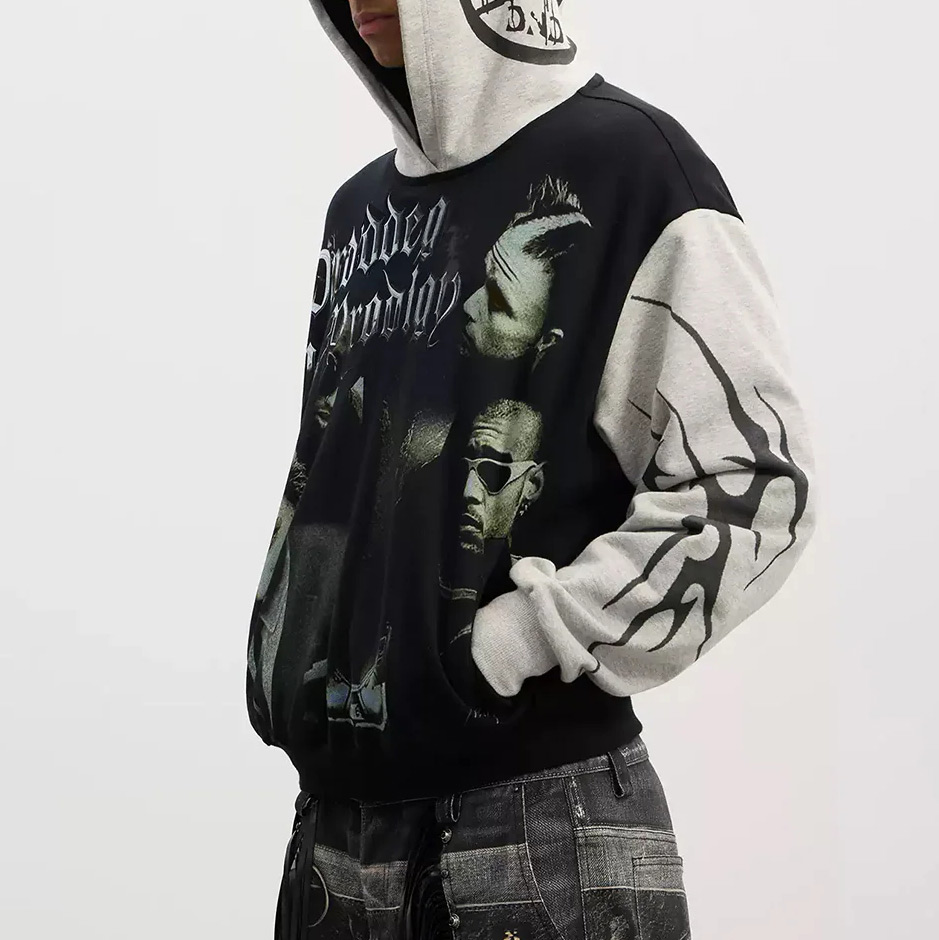

In today’s streetwear market, every hoodie is more than just a garment—it’s a statement of brand culture, technical innovation, and consumer expectation. As heavyweight hoodies dominate global streetwear drops, the importance of understanding GSM (grams per square meter) has become a core skill for every established streetwear label.

For brands scaling up or seeking to lock in quality, GSM is the hidden engine behind structure, drape, durability, and even the vibe your hoodie delivers on the street. So how do the world’s top manufacturers select the “right” GSM? This guide cuts through the noise, breaking down the four most common GSM ranges used in premium hoodie manufacturing, and how brands can leverage GSM strategy to drive both creative and commercial success.

▸ Mastering GSM selection is critical for hoodie structure, print performance, and customer satisfaction.

▸ Top streetwear brands use 320–400gsm for mainstream hoodies and 400–500gsm for heavyweight, luxury, and oversized styles.

▸ OEM hoodie manufacturers and oem clothing suppliers offer tailored fabric solutions, including sustainable blends, to match brand identity and market positioning.

▸ Robust fabric testing and precise GSM control ensure consistency from samples to bulk orders, reducing risk for scaling brands.

▸ Strategic use of GSM enables brands to innovate with fit, silhouette, and texture—creating signature products that stand out in a crowded market.

What Does GSM Mean and Why Does It Matter for Streetwear Hoodie Manufacturers?

GSM (grams per square meter) is the universal measurement for fabric weight and thickness—directly impacting the hand feel, warmth, structure, and long-term performance of a hoodie. In the streetwear world, GSM isn’t just a technical spec; it’s part of the brand’s visual and tactile DNA. Heavyweight hoodies (400+ gsm) have become a global trend for their premium look, substantial drape, and ability to hold complex graphics or embroidery without sagging. Lighter options (280–320gsm) remain popular for transitional seasons or athleisure lines, prized for their comfort and layering flexibility. Ultimately, selecting the best gsm for hoodies means balancing your design intent, end-user expectation, and commercial targets—a decision best made in partnership with a streetwear hoodie manufacturer who understands the nuances of fabric science, street culture, and supply chain agility.

What Are the Top 4 GSM Ranges Used by Leading OEM Hoodie Manufacturers?

While there’s no “one-size-fits-all” answer, data from leading OEM hoodie manufacturers worldwide shows four dominant GSM categories:

Note: The higher the GSM, the greater the material cost and production complexity. Ultra-heavyweight (500gsm and above) hoodies are typically more expensive and used for specialty or high-impact collections.

Want something even more unique?

Brands seeking maximum structure, cultural edge, or visual impact are increasingly exploring 550–600gsm or custom-developed heavyweight fabrics. These ultra-heavy options are rarely available off-the-shelf and require advanced technical support and sourcing. While cost per unit rises significantly, the result is a hoodie with unmatched silhouette, durability, and market distinctiveness. If your brand needs a truly standout piece, consider working with a manufacturer that can develop custom high-GSM textiles tailored to your creative vision.

How Does GSM Impact Hoodie Fit, Durability, and Printing Quality?

GSM is not just about “heavy vs. light”—it shapes the whole product experience:

- Fit & Drape: Higher GSM fabrics hold their shape and are less prone to stretching out. This is critical for oversized or boxy fits where silhouette integrity is everything.

- Durability: Dense fabrics withstand repeated washing, abrasion, and retain graphics or embroidery far better over time.

- Print & Embroidery Performance: High gsm materials minimize print cracking, bleeding, or warping. Complex screen printing, DTG, and 3D embroidery require stable, dense surfaces for crisp, lasting results.

- Shrinkage & Recovery: Properly sourced and pre-treated heavyweight fabrics (by trusted oem clothing suppliers) reduce post-wash shrinkage—a critical factor for customer satisfaction and minimizing returns.

How Should Streetwear Brands Choose Between 400gsm and 500gsm Hoodie Manufacturers? What About Custom 550–600gsm?

Both 400gsm and 500gsm hoodies represent the high end of the market, but their applications differ:

- 400gsm Hoodies: Often selected for mainline collections, these provide a hefty, “premium” feel without being uncomfortably bulky. They’re ideal for drop-shoulder, boxy, or slightly structured fits, and can handle bold graphics and custom pigment washes.

- 500gsm Hoodies: These are ultra-heavy, usually reserved for limited runs, luxury collaborations, or when a truly substantial “statement” piece is required. Brands working with a 500 gsm hoodie manufacturer gain access to rare, specialty fabrics—ideal for when you need your collection to stand out in the most competitive spaces.

- 550–600gsm Custom Options: For brands seeking extreme structure, exaggerated silhouettes, or culture-driven design language (e.g., to reference 90s hip-hop, Y2K maximalism, or heritage athleticwear), custom 550–600gsm fabrics are an option. This requires working with an experienced supplier who can source and produce to exacting specs. Costs are higher, but the result is a product with unique visual and tactile impact. At Groovecolor, we can help you develop these ultra-heavyweight textiles, matching the fit and cultural intent of your concept.

How Are Global Streetwear Markets Defining the “Best GSM for Hoodies”?

From LA to London, Tokyo to Paris, the definition of “best gsm for hoodies” is shifting upward as premiumization and “weight is luxury” become industry mantras. According to Statista, the US and Europe now see 400–500gsm as standard for top-tier streetwear hoodies, a sharp rise from the 320–360gsm norm just a few years ago. WGSN’s material forecasts highlight the rise of hybrid blends and eco-recycled content in Asian markets, while Vogue Business reports a surge in capsule and collab drops using 500gsm+ fabrics to create collectible, limited-edition pieces.

Sustainability is a rising differentiator: more global brands are requesting recycled, traceable, or certified cottons for all gsm ranges, ensuring compliance with retailer and end-user expectations.

Sources:

Statista: Global Streetwear Market Insights

WGSN: Fabric & Materials Reports

Vogue Business: The Heavyweight Hoodie Trend

For scaling brands, this means partnering with a streetwear hoodie manufacturer who can source, test, and scale heavyweight fabrics—without sacrificing flexibility for smaller test runs or urgent bulk orders.

Note: As GSM increases, so do material costs, minimum order requirements, and production complexity. Ultra-heavy options (500–600gsm) are best for brands looking to make a cultural statement or define new silhouettes, and require technical development and investment.

How to Work With Your Manufacturer to Achieve the Perfect GSM?

- Start with a tech pack: Clearly specify your gsm target, fabric type, and preferred composition.

- Request swatches: Always sample multiple gsm/fabric blends, especially when planning bold graphics, embroidery, or washes.

- Validate via third-party tests: Don’t just trust factory numbers—request lab reports for gsm, shrinkage, and colorfastness.

- Pilot run: Before bulk, run a 50–100 piece test order to check fit, drape, and after-wash stability in real use.

- Leverage expertise: Top manufacturers (Groovecolor and others) proactively suggest optimizations—whether that’s gsm tweaks, blend changes, or finishing processes—to ensure your design intent is fully realized at scale.

Frequently Asked Questions

What is GSM and how does it affect hoodie quality?

GSM (grams per square meter) is the metric for fabric weight, which directly impacts thickness, warmth, structure, drape, and durability. In hoodies, a higher GSM generally means a denser and heavier material, resulting in a more premium feel, stronger structure, and enhanced longevity. However, the ideal GSM depends on your collection’s goals: lightweight hoodies are suited for layering and summer drops, while heavyweight hoodies are prized for their substantial feel, warmth, and ability to hold structure and bold prints.

What GSM should I choose for my streetwear brand’s hoodie?

For most mainstream streetwear releases, 320–400gsm offers an ideal balance of comfort, drape, and customizability. For luxury, oversized, or statement pieces, 400–500gsm is now the go-to. Ultra-heavyweight (550–600gsm) options are best for brands aiming for maximum structure, dramatic silhouettes, or cultural reference points, and require custom development with an experienced manufacturer. Always sample multiple GSMs, review real-life wear and washing results, and match your selection to both customer climate and brand positioning.

Are higher GSM hoodies always better?

Not necessarily. While heavier hoodies (400gsm and above) provide enhanced warmth, durability, and premium visual impact, they may be too warm or rigid for some climates, uses, or customer preferences. Lower GSM hoodies (280–320gsm) are lighter and more flexible, perfect for layering and transitional seasons. The "best" GSM is one that fits your brand identity, intended fit, price point, and target market. It's smart to offer multiple GSM options across collections and rely on real market feedback.

What sustainable options exist for heavyweight hoodies?

Top manufacturers offer heavyweight hoodies using recycled cotton, organic or BCI-certified blends (with 400–600gsm weights possible), water-saving or low-impact dyeing and washing techniques, and compliance with global certifications such as OEKO-TEX®, GOTS, or SMETA 4P. Always request certification documents, check for traceability, and ask your supplier to recommend the best sustainable options for your specific GSM and design requirements.

Conclusion: The Future of GSM and Streetwear Hoodie Manufacturing

As the global streetwear scene evolves, GSM has become a strategic lever for product quality, brand positioning, and supply chain resilience. Brands that master GSM selection, work with experienced streetwear hoodie manufacturers, and commit to technical excellence will be best positioned to scale, innovate, and lead the next generation of street-driven apparel.

Groovecolor stands at the forefront, partnering with top brands worldwide to deliver consistent, high-quality hoodies across every GSM range—with scalable capacity, certified processes, and a proven record for bringing street culture to life.