From Screen to DTG, Sublimation, and Heat Transfer: The Ultimate Printing Playbook for Streetwear Clothing Manufacturers

From Screen to DTG, Sublimation, and Heat Transfer: The Ultimate Printing Playbook for Streetwear Clothing Manufacturers

In today’s streetwear industry, mastering the full spectrum of printing—from screen printing to DTG (direct-to-garment), sublimation, and heat transfer, is essential for every streetwear clothing brands aiming to deliver true quality and brand-defining graphics. Each technique shapes not only the look but also the feel, durability, and retail impact of your apparel. This ultimate playbook demystifies how top-tier streetwear clothing manufacturers select, execute, and combine advanced printing methods, ensuring every collection stands out—whether you’re scaling up, dropping limited editions, or experimenting with cutting-edge fabric and artwork.

Why Is Printing Technique Selection Critical for Streetwear Clothing Brands?

For streetwear clothing brands, the choice of printing technique goes beyond simple decoration—it’s an operational and brand-defining decision. Streetwear consumers expect graphic T-shirts, hoodies, and jackets to retain their visual power and tactile feel after countless wears and washes. A print that cracks, fades, or feels plasticky can quickly ruin the perceived value of an entire collection. Meanwhile, the wrong printing process can slow down your production, raise costs, or limit design freedom, especially when scaling from small batch market tests to high-volume releases.

The most advanced streetwear clothing manufacturers integrate multiple printing techniques—screen printing, DTG, sublimation, and heat transfer, into their workflow. This enables them to match the right process to every fabric, graphic style, and production volume, delivering not just great-looking products, but garments that actually meet the expectations of today’s global streetwear market. As this article will reveal, understanding the strengths, limitations, and creative potential of screen printing, DTG, sublimation, and heat transfer is now essential for any manufacturer or streetwear brand that wants to stay ahead in 2025 and beyond.

Screen Printing: The Backbone of Authentic Streetwear Graphics

Screen printing remains the industry standard for most high-end streetwear clothing manufacturers. The process uses layered mesh screens for each ink color, allowing for bold, opaque graphics with remarkable durability and texture. This is the method behind classic streetwear pieces—think oversized logos, varsity-style lettering, and vibrant all-caps slogans.

When executed by a professional manufacturer, screen printing achieves unmatched color saturation, even on heavyweight or dark fabrics. Specialty inks (like puff, metallic, or glow-in-the-dark) bring extra dimension and hype appeal. Key advantages include superior resistance to washing and abrasion, cost efficiency for medium-to-large runs, and the ability to experiment with layering and textures.

- › Common pitfalls with unprofessional printers include blurry details (from poor mesh tension), color misalignment, inconsistent ink curing (which leads to cracking), and using non-compatible inks on technical fabrics.

- › The best streetwear manufacturers invest in high-end equipment, skilled color separation, and multi-stage quality checks—ensuring every batch matches the sample and every graphic pops.

DTG Printing: Photorealistic Art and the Rise of Digital Streetwear

Direct-to-garment (DTG) printing has transformed what’s possible for streetwear clothing manufacturers who want to push artistic boundaries. This inkjet technology enables full-color, high-resolution graphics—think gradients, fine art illustrations, and even photographic images—directly onto the fabric. DTG works best on 100% cotton or high-cotton blends and produces a print that feels like part of the fabric, rather than a plastic layer.

Top-tier manufacturers utilize advanced pre-treatment and color management to achieve vibrant, long-lasting results—even on dark or oversized garments. This method is perfect for limited-edition drops, rapid sampling, or brands that thrive on constant design updates. However, it’s critical to understand that DTG is more sensitive to fabric choice, garment preparation, and post-print curing. Brands choosing a DTG-first approach must work with partners who offer premium ink systems, automated pre-treatment, and rigorous wash testing to avoid dull or short-lived prints.

- › Amateurs often skip or poorly execute pre-treatment, resulting in faded or blotchy graphics—especially on dark T-shirts or hoodies.

- › The right streetwear clothing manufacturer will always advise on fabric compatibility and run multi-cycle wash tests before bulk production.

Sublimation Printing: Unleashing All-Over Prints and Performance Streetwear

For brands aiming for full-coverage graphics, seamless pattern integration, or bold color saturation on polyester garments, sublimation printing is the technique of choice. This process uses heat and pressure to turn dyes into gas, which then bonds with the very fibers of the fabric—resulting in permanent, ultra-vivid prints with no extra texture or weight.

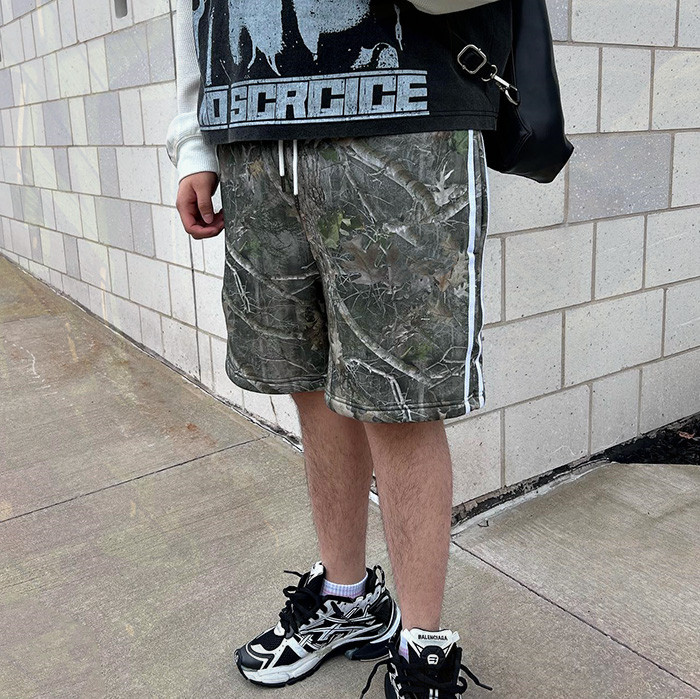

Sublimation is the backbone of streetwear’s ongoing fusion with activewear and tech-driven materials. Think statement tracksuits, Y2K mesh jerseys, and all-over camo or gradient effects. The downside? Sublimation only works with high-polyester content fabrics, and achieving perfect registration (especially on multi-panel or cut-and-sew pieces) requires serious technical know-how. Leading manufacturers use advanced pattern matching and color management, while subpar print houses may deliver blurry, faded, or misaligned results that instantly cheapen your collection.

- › Avoid any supplier who proposes sublimation on cotton or fails to offer fabric sampling—true experts will show test prints and explain color profiles before proceeding.

Offset, Heat Transfer & Branding: Beyond Garment Prints—The Streetwear Brand Experience

The best streetwear clothing manufacturers know that true print mastery goes beyond garments alone. Techniques like offset printing and, especially, heat transfer are now central to premium brand building—delivering ultra-sharp hang tags, custom packaging, transfer labels, and bold patches that bring an added layer of distinction to any collection.

Top manufacturers manage color consistency across all branded materials, use premium cardstocks, and offer a full suite of branding solutions from garment labels to outer packaging. Heat transfer technology enables crisp, multi-color patches and logos on fabrics where direct printing isn’t viable, and is vital for performance fabrics, accessories, and details that require precise placement or unique material compatibility. This holistic approach separates true luxury streetwear suppliers from factories focused solely on price and speed.

- › Pro brands treat hang tags and custom patches as part of the product—never an afterthought.

- › Insist on reviewing branded packaging samples and heat transfer quality before approving production.

What Sets a Leading Streetwear Clothing Manufacturer Apart in Printing?

In the streetwear industry, not all manufacturers are created equal. True leaders combine culture fluency with technical precision: they understand how a single print can shape a brand’s reputation, how new washes or mixed-media graphics fuel hype cycles, and how technical choices (mesh count, ink chemistry, curing parameters) impact everything from hand-feel to garment longevity.

The best streetwear clothing manufacturers take a consultative approach. They offer real guidance on technique selection, prototype rapidly, run bulk and wash tests, and provide transparency on every step. They invest in R&D—new sustainable inks, eco-wash options, digital workflow upgrades—to keep their clients ahead of trends. Critically, they ensure every bulk order matches the sample, every time, and can scale production rapidly as market response demands. In today’s landscape, it’s those manufacturers who have mastered—and can combine—screen printing, DTG, sublimation, and heat transfer at scale that truly define the future of streetwear.

- › If your manufacturer isn’t able to explain the “why” behind every print choice—or doesn’t test at each step—your brand is at risk.

As a leading streetwear clothing manufacturer, Groovecolor stands out by blending technical mastery, culture-first design insight, and scalable production capacity. Our capabilities cover all advanced printing techniques—screen printing, DTG, sublimation, heat transfer, and branded packaging. Every project begins with in-depth consultation, moves through multi-stage QC, and ends with vibrant, durable, and globally competitive streetwear garments. For brands that refuse to compromise, Groovecolor offers both the expertise and the agility to turn any vision into commercial reality.

FAQ

Which printing technique is most durable for streetwear clothing?

Screen printing is generally the most durable, especially when using quality inks and proper curing. It offers exceptional wash resistance and retains vibrancy even after heavy wear, making it the go-to for long-lasting streetwear pieces.

Can I use DTG printing for every type of streetwear fabric?

DTG is best for 100% cotton or high-cotton blends. It struggles with polyesters and certain blends. A quality streetwear clothing manufacturer will guide you on the best fabric options for your graphic and ensure proper pre-treatment and curing for wash durability.

What is the advantage of sublimation for streetwear brands?

Sublimation printing enables all-over, seamless designs on polyester garments, with ultra-bright color and no hand-feel. It's ideal for active-inspired streetwear, bold patterns, and performance fabrics, but doesn't work on cotton.

How do I choose the right manufacturer for my streetwear printing needs?

Choose a partner with proven experience in both design and production, mastery across multiple printing methods, and a track record for quality, consistency, and transparent consultation. Always review samples, QC processes, and fabric recommendations before committing to bulk orders.

Contact Groovecolor for a detailed consultation on the best printing strategies for your next collection—where culture, technology, and craftsmanship come together.