Building Your Streetwear Brand with Private Label Shirts: An Expert’s 2026 Guide for Industry Leaders

Building Your Streetwear Brand with Private Label Shirts: An Expert's 2026 Guide for Industry Leaders

In the hyper-competitive global streetwear market, which is projected to surpass $637 billion by 2032 [1], the humble shirt has evolved from a basic staple into a primary canvas for brand identity. For established streetwear leaders, the challenge is no longer just about design; it is about execution at scale. This is where the strategic use of private label shirts becomes a critical lever for growth. Moving beyond generic blanks to create fully customized garments allows a brand to control every detail, including fit, fabric, color, and finish, transforming a simple piece of apparel into a signature statement. This guide provides a 2026 framework for leveraging private label manufacturing to not only elevate your product line but also to build a more resilient and scalable supply chain. As we will explore, partnering with a manufacturer that understands the nuances of streetwear, such as the integrated systems seen at specialists like Groovecolor, is fundamental to translating bold concepts into commercially successful, high-quality collections.

Key Takeaways for Streetwear Brands

- ▸ Beyond the Blank: Transitioning to private label shirts unlocks full control over fit, fabric weight (from 180 to 400gsm), and custom finishes, creating signature products that are impossible to replicate with off-the-shelf garments.

- ▸ Manufacturing as a Strategic Asset: The right manufacturing partner is not a vendor but a strategic asset. Look for integrated capabilities, from digital pattern-making and in-house wash labs to multi-technique graphic application, to ensure your vision is executed flawlessly at scale.

- ▸ Quality as a System, Not a Checkpoint: For mature brands, consistent quality is non-negotiable. A robust quality management system, like the 8-step process from raw material inspection to final AQL checks, is essential for mitigating risk and protecting brand reputation.

- ▸ The China Advantage Reimagined: The narrative has shifted from low-cost production to advanced technical execution. Leading Chinese manufacturers now offer unparalleled expertise in complex washes, heavyweight fabrics, and intricate embellishments that are often difficult to source elsewhere.

Why Private Label Shirts Are a Litmus Test for Brand Maturity

For a nascent brand, the path to market often begins with screen-printing on pre-made blanks. It is a logical, low-risk entry point. However, as a brand gains traction and cultivates a discerning audience, the limitations of this model become starkly apparent. The decision to move from white label to private label manufacturing is a pivotal moment that separates fleeting trends from enduring brand legacies. It signifies a shift from merely selling products to architecting a complete brand experience. This transition is not just about putting a custom tag on a generic shirt; it is about owning the entire product narrative, from the specific GSM of the cotton to the precise drape of an oversized silhouette.

Mature streetwear brands understand that their most loyal customers can feel the difference. They recognize the subtle distinction between a standard 180 GSM tee and a substantial 250 GSM heavyweight shirt. They appreciate the nuanced execution of a vintage wash or the sharp detail of a high-density print. Private label production is the only way to control these variables with precision. It allows a brand to create a core product that is uniquely its own, establishing a tactile and visual signature that builds brand equity and fosters customer loyalty. In a market saturated with fleeting designs, a perfectly executed custom shirt becomes a tangible piece of the brand's identity.

The Anatomy of a High-Quality Custom Streetwear Shirt

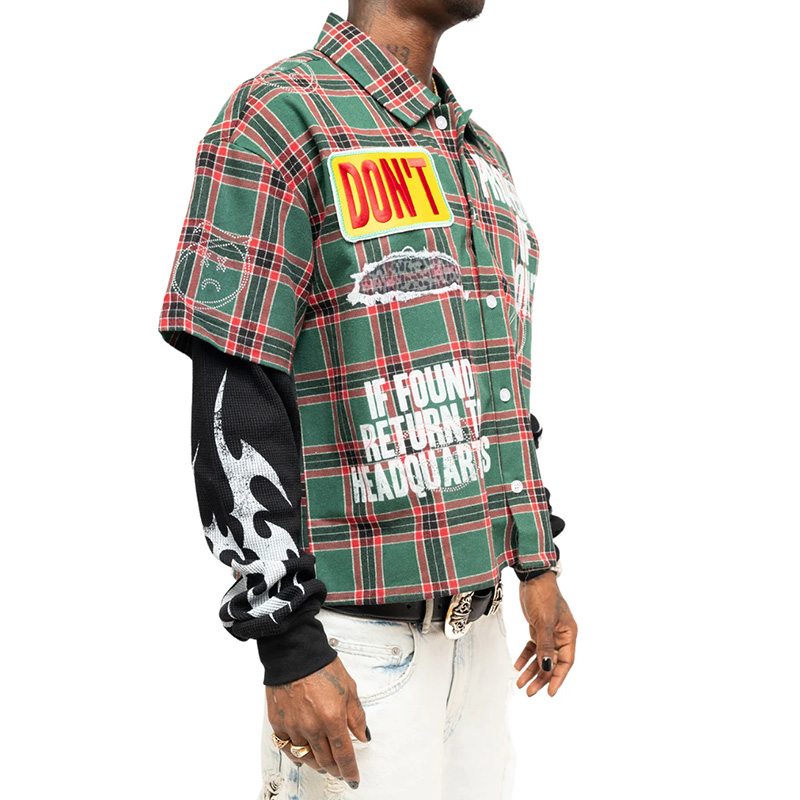

Creating a truly premium custom streetwear shirt requires a deep understanding of its constituent parts. It is a synthesis of fabric, fit, and finish. Each element must be deliberately chosen and expertly executed to contribute to the final garment's overall impact. Here is a breakdown of the critical components that the best shirt manufacturers focus on.

1. Fabric: The Foundation of Feel and Form

Fabric Weight (GSM)

Fabric Type

2. Fit and Silhouette: The fit is the soul of a streetwear shirt. It is what transforms a simple garment into a fashion statement. While trends evolve, key silhouettes remain central to the streetwear aesthetic. A knowledgeable manufacturer must have pattern makers who are fluent in these shapes. The Oversized Fit is characterized by a generous cut through the body and longer sleeves, creating a relaxed and comfortable drape. The Boxy Fit is a wider, shorter cut with a straight silhouette, often featuring a higher neckline, providing a structured, modern look. The Drop Shoulder style positions the shoulder seam lower down the arm, creating a slouchy, laid-back feel that is synonymous with high-end streetwear.

3. Finishing and Details: The small details are what elevate a good shirt to a great one. These finishing touches are where a brand's commitment to quality becomes truly evident. This includes everything from the construction of the collar (a thick, durable rib is a must for premium tees) to the stitching on the seams. More advanced techniques involve garment washing, which can dramatically alter the texture and appearance of the final product. Techniques like enzyme washes for softness, stone washes for a worn-in feel, or acid washes for a vintage look are all part of the private label toolkit [10]. These processes require specialized equipment and expertise, making them a key differentiator for high-quality clothing manufacturers in China and beyond.

How to Choose a Private Label Shirt Manufacturer: A 2026 Vetting Framework

Selecting the right manufacturing partner is arguably the most critical decision a streetwear brand will make. The right partner acts as an extension of your brand, a guardian of your quality, and an enabler of your growth. The wrong one can lead to production nightmares, damaged reputation, and financial loss. As the industry evolves, the criteria for what makes a great manufacturer have become more sophisticated. It is no longer enough to simply ask for a price list and MOQ. Mature brands must conduct a thorough, multi-faceted evaluation. Here is a comprehensive framework for vetting potential private label clothing manufacturers in 2026.

This structured approach moves the conversation beyond a simple price comparison. It reframes the selection process as a search for a long-term strategic partner. While US private label clothing manufacturers offer benefits in proximity and shipping times, many brands find that the advanced technical capabilities and integrated supply chains of top-tier Chinese manufacturers provide a decisive advantage in creating complex, high-quality streetwear. Streetwear clothing manufacturers such as Groovecolor, which operate with integrated pattern development, in-house washing control, and batch-level quality locking, are structurally positioned to support brands navigating this stage of growth. Ultimately, the best clothing suppliers are those who not only meet your technical requirements but also align with your brand's values and growth ambitions.

Navigating the Private Label Production Process: From Tech Pack to Delivery

Transitioning to private label manufacturing involves a structured, collaborative process. Understanding each stage is crucial for managing timelines, costs, and quality. While every manufacturer has a slightly different workflow, the fundamental steps remain consistent. A transparent and experienced partner will guide you through this journey, turning your creative concepts into tangible, market-ready products. Here is a step-by-step guide to the typical private label production lifecycle, designed for established brands looking to optimize their operations.

Step 1: The Tech Pack - Your Product Blueprint. The tech pack (technical pack) is the single most important document in the manufacturing process. It is a detailed blueprint that communicates every specification of your design to the factory. A comprehensive tech pack minimizes ambiguity and reduces the risk of errors [2]. It should include: detailed sketches or CADs of the garment, precise measurements and grading for all sizes, fabric specifications (composition, weight, color), details on all trims (buttons, zippers, drawstrings), and high-resolution artwork for any prints or embroidery. Providing a thorough tech pack is the first sign of a professional brand and sets the stage for a smooth production run.

Step 2: Sampling - Bringing the Vision to Life. Once the factory has reviewed your tech pack, they will create a prototype or sample. This is your first opportunity to see and feel the physical garment. The sampling stage is iterative. You will review the first sample for fit, construction, and overall quality. It is common to go through one or two rounds of revisions to perfect the details. A reliable manufacturer will provide constructive feedback during this stage, suggesting potential improvements to enhance manufacturability or durability [3]. For example, they might recommend a different stitching technique for a high-stress seam or a more suitable fabric finish for a desired wash effect. This collaborative approach is a hallmark of a true manufacturing partner.

Step 3: Pre-Production and Sourcing. After you approve the final sample, the process moves into pre-production. The factory will source the bulk fabric and trims required for your order. This is also when they prepare the patterns for mass production and calibrate the machinery for your specific design. A well-organized manufacturer with a strong supply chain can significantly shorten this phase. For instance, factories that maintain a stock of high-quality, in-demand fabrics can move into production much faster than those who have to source everything from scratch for each order.

Step 4: Bulk Production - Cutting, Sewing, and Finishing. This is where your collection is manufactured at scale. The process begins with cutting the fabric, which is often done with automated laser cutters to ensure precision and consistency across thousands of pieces. The cut pieces then move to the sewing lines, where skilled operators assemble the garments. For streetwear, this stage often involves complex graphic applications. Whether it is a multi-color screen print, a detailed DTG graphic, or intricate 3D puff embroidery, these processes are integrated into the production flow. Finally, the garments go through finishing, which can include washing, pressing, and attaching hangtags and labels.

Step 5: Quality Control - The Final Gatekeeper. Before the products are packaged, they must pass a final, rigorous quality control inspection. This is not a cursory glance. Professional QC teams use a statistical sampling method known as AQL (Acceptable Quality Limit) to inspect a portion of the production run against a detailed checklist [15]. They check for everything from measurement accuracy and stitching defects to color consistency and print placement. Any issues are flagged, and if the number of defects exceeds the predetermined AQL, the entire batch may be held for further inspection or rework. This systematic approach ensures that the products that leave the factory meet your brand's quality standards.

Step 6: Packaging and Logistics. The final step is packaging and shipping. The garments are folded, poly-bagged, and packed into cartons according to your specifications. The manufacturer will then coordinate with freight forwarders to ship the goods to your warehouse or distribution center. Understanding the logistics, including shipping times and customs clearance, is essential for planning your product launch and ensuring your collection arrives on schedule.

The Art and Science of Graphic Application: Printing and Embroidery

In streetwear, the graphic is often the hero. The choice of how to apply that graphic, whether through printing or embroidery, has a profound impact on the final garment's aesthetic, feel, and perceived value. The best shirt manufacturers offer a wide array of techniques and can provide expert guidance on which method is best suited for a particular design and fabric. Here is a closer look at the most common techniques and their applications in modern streetwear.

Printing Techniques

Screen Printing

Direct-to-Garment (DTG)

Embroidery Techniques

Flat Embroidery

3D Puff Embroidery

Chenille/Towel Embroidery

Deep Dive: The Nuances of Streetwear Fabric and Fit

While the previous section outlined the basics of fabric and fit, a deeper understanding is essential for brand leaders aiming for the top tier of the market. The interaction between fabric weight, composition, and the intended silhouette is a complex interplay that defines the garment's character. For instance, a 400 GSM heavyweight cotton jersey will not just feel substantial; its inherent stiffness is what allows a boxy fit to maintain its sharp, architectural lines without collapsing. In contrast, a 250 GSM combed cotton, while still premium, offers a softer drape that might be better suited for a relaxed, oversized fit that moves with the wearer. The best clothing suppliers in China have dedicated teams for fabric sourcing and development, allowing brands to create custom-milled fabrics to achieve a specific hand-feel or performance characteristic.

Furthermore, the construction of the garment itself plays a vital role. The choice of a tubular knit versus a side-seamed construction can affect both fit and how a garment holds its shape after repeated washing. Tubular knit tees, made from a single piece of fabric, have no side seams, offering a clean, uninterrupted canvas for graphics. However, they can be more prone to twisting. Side-seamed construction offers a more tailored and consistent fit. Similarly, the construction of the collar is a critical detail. A premium streetwear shirt will feature a thick, tightly knit 1x1 rib collar that is reinforced with taping from shoulder to shoulder. This not only feels more substantial but also prevents the dreaded 'bacon neck' that plagues lower-quality garments. These are the granular details that a seasoned private label manufacturer will understand and execute flawlessly.

The Modern China Advantage: Beyond Cost to Technical Mastery

For years, the narrative surrounding manufacturing in China was centered almost exclusively on cost. However, for the premium streetwear market in 2026, that narrative is outdated and incomplete. While cost-effectiveness remains a factor, the true advantage of partnering with top-tier Chinese manufacturers now lies in their unparalleled technical mastery, integrated supply chains, and deep specialization in the complex demands of streetwear. This is a critical distinction for established brands, for whom quality and execution are paramount.

The sheer scale and maturity of China's textile industry have created an ecosystem that is simply unrivaled. This ecosystem provides immediate access to a vast and diverse range of raw materials, from custom-milled heavyweight cotton to innovative synthetic blends. More importantly, it has fostered a deep specialization in the niche techniques that define modern streetwear. Processes like complex garment washes (acid, stone, enzyme), multi-layer embroidery, and advanced printing effects are not just available; they have been perfected through decades of experience and investment [11]. Many of the best clothing suppliers in China have built in-house labs and dedicated R&D teams focused solely on pushing the boundaries of these techniques, offering brands a level of creative possibility that is often unattainable in other manufacturing regions.

Furthermore, the leading China high quality clothing manufacturers have invested heavily in technology and infrastructure. They operate state-of-the-art facilities equipped with automated cutting machines, advanced printing and embroidery hardware, and sophisticated quality control systems. This investment translates into greater precision, consistency, and efficiency, particularly at scale. For a brand producing thousands of units, the ability to ensure that the first piece and the last piece are virtually identical is a non-negotiable requirement. The modern Chinese manufacturing partner is not a low-cost alternative; it is a high-tech, specialized powerhouse capable of executing the most ambitious creative visions with a level of quality and consistency that the global streetwear market demands.

Cultural Fluency: The Unseen Element in a Great Manufacturing Partner

Beyond technical skill and production capacity lies a more subtle, yet equally critical, attribute: cultural fluency. Streetwear is not just apparel; it is a cultural language spoken through fabric, fit, and graphics. A manufacturer that does not understand this language can execute a tech pack with technical precision yet still miss the mark. Cultural fluency is the ability to grasp the 'why' behind the 'what', to understand the cultural context and aesthetic intent of a design.

This understanding manifests in numerous ways. A culturally fluent partner knows that a 'vintage wash' is not just a chemical process but an exercise in creating authenticity; they know how to achieve a fade that looks naturally aged rather than artificially distressed. They understand that the placement of a graphic on an oversized tee is not arbitrary but a deliberate choice that affects the garment's entire attitude. They can offer meaningful suggestions, such as recommending a specific embroidery technique to better capture the grit of a skate-inspired design or a particular dye treatment to evoke the nostalgia of Y2K fashion. This level of understanding can only be developed through years of dedicated focus on the streetwear market. It is a key differentiator that separates a mere order-taker from a true creative and strategic partner.

Trade-offs and Risks in Private Label Manufacturing

While the benefits of private label manufacturing are substantial, the path is not without its challenges. A clear-eyed understanding of the potential risks and trade-offs is essential for any brand leader. The most significant trade-off is the increased upfront investment in both time and capital. Unlike ordering from a stock catalog, developing a custom product requires a significant investment in sampling, development, and higher MOQs. This ties up capital and necessitates a longer lead time before the product is ready for market. Brands must have a solid financial footing and a clear product strategy to navigate this initial phase.

Another significant risk lies in the dependency on a single manufacturing partner for a specific product. If that relationship sours, or if the factory experiences production issues, it can bring a brand's entire supply chain to a halt. This is why the initial vetting process is so critical. Diversifying manufacturing partners across different product categories can be a prudent long-term strategy to mitigate this risk. Furthermore, intellectual property (IP) protection is a valid concern, especially when working with overseas manufacturers. Brands must ensure they have clear agreements in place that define ownership of the designs and patterns. Working with reputable, well-established manufacturers who have a long history of partnering with international brands can significantly reduce this risk.

Finally, there is the risk of quality fade. This is a phenomenon where the quality of the product gradually declines over subsequent production runs as the manufacturer seeks to cut costs [6]. This can be insidious and difficult to detect without a rigorous, ongoing quality control program. Brands must remain vigilant, conducting regular inspections and maintaining open lines of communication with their manufacturing partner. The temptation to switch to a cheaper supplier is ever-present, but mature brands understand that the long-term cost of a damaged reputation far outweighs any short-term savings. The key to mitigating these risks lies in the same principles that define a successful private label strategy: thorough vetting, clear communication, and a focus on building a long-term, transparent partnership.

The Future of Private Label: Technology and Sustainability in 2026 and Beyond

As we look towards 2026 and beyond, the landscape of private label manufacturing is being reshaped by two powerful forces: technology and sustainability. For streetwear brand leaders, staying ahead of these trends is not just about staying relevant; it is about building a more efficient, responsible, and resilient business. The integration of technology is revolutionizing the production process. Digital pattern-making and 3D sampling are becoming standard, allowing brands to visualize and iterate on designs with incredible speed and accuracy, reducing the time and waste associated with physical sampling. AI-powered quality control systems are emerging, capable of detecting fabric defects with a precision that surpasses the human eye. On the production floor, automated cutting and sewing technologies are enhancing consistency and efficiency.

Simultaneously, the demand for sustainable and ethical production has moved from a niche concern to a mainstream expectation. This goes beyond simply using organic cotton. It encompasses the entire supply chain, from the responsible sourcing of raw materials to the use of eco-friendly dyes and chemicals. Waterless dyeing techniques and ozone washes are gaining traction as alternatives to traditional, water-intensive processes. Brands are increasingly looking for manufacturers who can provide transparency and traceability, offering visibility into every stage of the production journey. Leading manufacturers are responding by investing in certifications like GOTS (Global Organic Textile Standard) and by implementing robust environmental management systems. For the modern streetwear brand, a commitment to sustainability is no longer a marketing talking point; it is a core component of brand integrity and a critical factor in choosing a long-term manufacturing partner.

Long-Term Implications: Building a Resilient Brand

The strategic shift to private label manufacturing is more than a production decision; it is a foundational investment in your brand's future. By taking control of your product, you move from being a reseller of commodities to a creator of unique assets. This control yields long-term benefits that compound over time. A consistent, high-quality product builds trust and loyalty, turning first-time buyers into lifelong advocates. A unique and identifiable product signature creates a moat around your brand, making it less susceptible to the whims of fleeting trends and the pressures of price competition. Furthermore, a well-vetted and reliable supply chain provides the stability and agility needed to navigate market volatility, scale operations, and seize new opportunities. For streetwear brands entering their next phase of growth, the decision is less about finding a cheaper factory and more about aligning with a manufacturing structure that understands the long-term cost of inconsistency and the immense value of a product that is truly your own.

Frequently Asked Questions for Custom Streetwear Shirts

What is the difference between private label and white label shirts?

Private label involves creating a unique product to your exact specifications, including custom fit, fabric, tags, and details. The product is exclusive to your brand. White label, on the other hand, involves putting your brand's label on a generic, pre-made garment that other brands can also sell [5]. For mature streetwear brands seeking differentiation, private label is the necessary path as it allows for full creative control and the development of a signature product.

How do I find the best shirt manufacturers, especially in China?

Finding the best clothing suppliers in China requires a multi-step vetting process. Look beyond basic directories and focus on manufacturers with a proven specialization in streetwear. Evaluate their technical capabilities by requesting samples of heavyweight fabrics, complex washes, and detailed embroidery. Scrutinize their quality management systems (QMS) and ask for social compliance audits like SMETA or BSCI. Prioritize clear communication and transparency. A high-quality clothing manufacturer will act as a partner, providing expert guidance throughout the process.

What is a realistic MOQ for custom streetwear shirts?

Minimum Order Quantities (MOQs) can vary significantly. While some factories cater to startups with very low MOQs, established brands should look for a partner offering strategic flexibility. A typical MOQ for fully custom private label shirts from a quality-focused factory might range from 50 to 200 pieces per color/style. This allows for market testing of new designs while still being scalable. The key is to find a manufacturer whose production model aligns with your brand's growth strategy, balancing initial order sizes with the capacity for large-scale reorders.

Why are US private label clothing manufacturers sometimes more expensive than those in China?

The cost difference often comes down to labor costs, regulatory expenses, and the scale of the manufacturing ecosystem. While US manufacturers offer advantages in shipping times and domestic communication, China's mature and highly integrated supply chain for textiles, trims, and specialized machinery often provides a cost and capability advantage, especially for complex streetwear. Many China high quality clothing manufacturers have invested heavily in advanced technologies for washing, printing, and embroidery that are difficult and expensive to replicate elsewhere, allowing them to produce intricate designs at a competitive price point.

References

[1] Fortune Business Insights. (2025). Streetwear Market Size, Share & Industry Analysis. Retrieved from https://www.fortunebusinessinsights.com/streetwear-market-110565

[2] Sewport. (n.d.). Private Label Clothing Manufacturing - What is it?. Retrieved from https://sewport.com/learn/private-label-manufacturers

[3] Lefty Production Co. (2024). Private Label Clothing Manufacturing: Everything You Need to Know. Retrieved from https://www.leftyproductionco.com/post/private-label-clothing-manufacturing-everything-you-need-to-know

[4] Shopify. (2026). How to Start a Clothing Brand in 14 Steps. Retrieved from https://www.shopify.com/blog/206934729-how-to-start-a-clothing-line

[5] Printful. (2024). The Complete Guide to Private and White Label Clothing. Retrieved from https://www.printful.com/blog/white-label-clothing

[6] InTouch Quality. (2021). How to Avoid Quality Fade With Clothing Manufacturers in China. Retrieved from https://www.intouch-quality.com/blog/how-to-avoid-quality-fade-with-clothing-manufacturers-in-china

[7] Eurofins. (2024). China GB: Entering the Chinese textiles and apparel market. Retrieved from https://www.eurofins.com/textile-leather/articles/china-gb-standards-entering-the-chinese-textiles-and-apparel-market/

[8] Printful. (n.d.). DTG vs. Screen Printing: Which One to Choose?. Retrieved from https://www.printful.com/blog/dtg-vs-screen-printing

[9] JCEE Fashion. (2025). 6 Common Embroidery Techniques for Streetwear Brands. Retrieved from https://jceefashion.com/blogs/blog/embroidery

[10] Hem Apparel. (2025). Intro to Garment Wash Techniques: Vintage, Acid, Enzyme & More. Retrieved from https://hem-apparel.com/blogs/resources/intro-to-garment-wash-techniques-vintage-acid-enzyme-more

[11] Clothing Producer. (2025). Vintage Wash T-shirt Techniques Explained. Retrieved from https://clothingproducer.com/vintage-wash-t-shirt-techniques/

[12] Printful. (n.d.). 15 T-Shirt Design Trends for 2026. Retrieved from https://www.printful.com/blog/design-trends

[13] Complex. (2026). 10 Fashion Trends We Think Will Run Streetwear in 2026. Retrieved from https://www.complex.com/style/a/mike-destefano/10-fashion-trends-we-think-will-run-streetwear-2026

[14] QIMA. (2025). Garment Quality Control & Inspection Procedures. Retrieved from https://blog.qima.com/inspection/garment-quality-inspection-procedures

[15] QIMA. (n.d.). Acceptable Quality Limit, AQL. Retrieved from https://www.qima.com/aql-acceptable-quality-limit