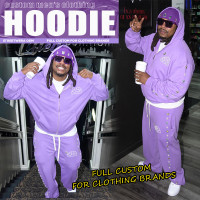

Finding the Best Quality Full Zip Up Hoodie Manufacturer: Essential Checklist for Global Fashion Brands in 2026

Finding the Best Quality Full Zip Up Hoodie Manufacturer: Essential Checklist for Global Fashion Brands in 2026

In the ever-evolving landscape of global fashion, the full zip up hoodie has transcended its utilitarian origins to become a definitive statement piece for streetwear brands. It’s a canvas for creativity, a symbol of comfort, and a critical component of any successful collection. Yet, for established brands, the challenge isn't just designing a compelling hoodie; it's finding a manufacturing partner capable of executing that vision at scale without compromising on quality. The search for the best quality full zip up hoodie manufacturer is a high-stakes endeavor, where the right partnership can elevate a brand, while the wrong one can lead to production nightmares and damaged reputations. As brands like yours look to solidify their market position in 2026, understanding the nuances of hoodie manufacturing becomes paramount. This guide provides an essential checklist for navigating this complex process, drawing on industry insights and best practices to help you identify a partner that aligns with your brand's commitment to excellence. For instance, a hoodie manufacturer like Groovecolor, with its deep expertise in streetwear and vertically integrated production, exemplifies the type of partner that can help brands navigate the complexities of quality, scale, and innovation.

Key Takeaways for Streetwear Brands

- ▸ Mastering the technical details of hoodie manufacturing, from fabric GSM to zipper quality, is non-negotiable for delivering a premium product that resonates with discerning consumers.

- ▸ An effective full zip up hoodie manufacturer does more than just assemble garments; they act as strategic partners, offering expertise in material sourcing, process optimization, and quality control to ensure your vision is realized flawlessly.

- ▸ Leveraging a manufacturer with a robust, vertically integrated supply chain and stringent quality control protocols, such as the AQL standard, is critical for maintaining consistency and scalability as your brand grows.

- ▸ For global brands, partnering with a hoodie manufacturer in China that holds certifications like SMETA 4-Pillar and ISO 9001 provides a significant advantage in terms of ethical production, quality assurance, and supply chain transparency.

Why the Full Zip Up Hoodie is a Litmus Test for Manufacturer Quality

The full zip up hoodie is more than just a staple of modern streetwear; it is a complex garment that serves as a revealing test of a manufacturer's capabilities. Unlike its simpler pullover counterpart, the zip-up hoodie introduces a range of technical challenges that can quickly expose weaknesses in a production line. The successful execution of a high-quality zip-up hoodie requires a harmonious blend of precision engineering, material science, and meticulous attention to detail. For established fashion brands, the ability of a potential manufacturing partner to master this garment is often a key indicator of their overall competence and reliability.

One of the most critical elements is the zipper itself. The integration of a zipper into a garment is not a simple matter of sewing on a component. It requires a deep understanding of fabric behavior, zipper mechanics, and the interplay between the two. A high-quality zipper, such as those from renowned suppliers like YKK, is a prerequisite, but it is only the starting point. The manufacturer must have the expertise to select the appropriate zipper type—be it metal, coil, or molded plastic—that complements the fabric's weight and drape. The insertion process must be executed with precision to prevent puckering, waving, or misalignment, which are common defects that can ruin the aesthetic of the final product. Furthermore, the zipper's durability and smooth operation are paramount, as a faulty zipper can render the entire garment useless and lead to customer dissatisfaction. A proficient custom zip up hoodies manufacturer will have rigorous testing protocols in place to ensure the longevity and performance of every zipper they use.

Beyond the zipper, the construction of a full zip up hoodie presents several other challenges. The placket, the strip of fabric where the zipper is attached, must be perfectly straight and reinforced to withstand the stress of repeated zipping and unzipping. The two front panels of the hoodie must be perfectly symmetrical, a task that becomes more complex with the addition of pockets, prints, or embroidery. Any slight deviation in the cutting or sewing of these panels will be immediately noticeable when the hoodie is zipped up. The hood itself must be constructed to have the right shape and volume, and its attachment to the body of the garment must be seamless and durable. These are the kinds of details that distinguish a premium product from a mass-market imitation, and they are the details that a top-tier hoodie manufacturing partner will obsess over.

In essence, the full zip up hoodie serves as a microcosm of the entire manufacturing process. It tests a factory's ability to source high-quality components, to execute precise and consistent sewing, and to implement rigorous quality control measures. For a global fashion brand, a flawless zip-up hoodie is a testament to their commitment to quality. Therefore, when evaluating potential manufacturing partners, it is wise to use the zip-up hoodie as a benchmark. A manufacturer that can produce an impeccable zip-up hoodie is likely to have the skills, processes, and mindset to deliver excellence across your entire product line. This is why the search for the best quality full zip up hoodie manufacturer is not just about finding a supplier; it's about finding a partner who can help you build your brand's reputation for quality and craftsmanship.

The 2026 Manufacturer Vetting Checklist: 7 Critical Pillars

As the streetwear market continues its upward trajectory, with projections indicating a global market size exceeding $250 billion by 2026 [4][5], the competition among brands is fiercer than ever. In this environment, product quality is not just a feature; it is the very foundation of brand loyalty and longevity. For established brands, the process of vetting a new full zip up hoodie manufacturer is a critical strategic decision that can have far-reaching implications. A comprehensive evaluation process must go beyond surface-level assessments and delve into the core operational, technical, and ethical pillars of a potential partner. This 7-pillar checklist is designed to provide a robust framework for global fashion brands to systematically evaluate and select a manufacturing partner that can meet the rigorous demands of the 2026 market.

Pillar 1: Mastery of Fabric and Materials

The tactile experience of a hoodie is its first and most lasting impression. A manufacturer's expertise in fabric is the cornerstone of a premium product. This goes far beyond simply offering a catalog of options; it involves a deep understanding of material science, sourcing, and the nuances of how different fabrics perform during production and in the hands of the consumer. A top-tier manufacturer will guide you through the complexities of fabric selection, ensuring that the final product not only looks and feels exceptional but also aligns with your brand's identity and quality standards.

The conversation around fabric quality inevitably starts with GSM (Grams per Square Meter). While a standard hoodie might fall in the 250-350 GSM range, the realm of premium streetwear begins at 400 GSM and can extend to 600 GSM for truly substantial, luxurious garments. A knowledgeable manufacturer will not just present you with a list of GSM weights; they will be able to articulate the specific characteristics of each weight class. They will explain how a 450 GSM French terry will drape differently from a 550 GSM brushed fleece, and how the choice of GSM will impact the hoodie's structure, warmth, and overall aesthetic. This level of expertise is crucial for achieving the desired silhouette, whether it's a structured, boxy fit or a more relaxed, oversized drape.

Beyond GSM, the choice of raw materials is a critical factor. The best quality hoodie manufacturers will have established relationships with reputable mills and suppliers, giving them access to a wide range of high-quality cottons, from premium long-staple varieties to organic and recycled options. They should be able to provide detailed specifications for each fabric, including composition, weave, and any special treatments or finishes. Furthermore, they should have a robust fabric inspection process in place to identify and reject any materials with defects such as inconsistencies in color, texture, or weight. This initial stage of quality control is fundamental to preventing problems from cascading down the production line.

Finally, a truly capable manufacturer will demonstrate a commitment to innovation in materials. They will be proactive in sourcing and developing new fabrics that can give your brand a competitive edge. This could involve exploring unique blends, sustainable alternatives, or custom-developed textiles that offer superior performance or a distinctive aesthetic. A partner who is invested in pushing the boundaries of material science is a partner who is invested in your brand's long-term success. When vetting a potential manufacturer, be sure to inquire about their fabric sourcing and development capabilities. Ask for samples, test reports, and case studies of how they have helped other brands achieve their material goals. A manufacturer's mastery of fabric is a clear indicator of their overall commitment to quality and innovation.

Pillar 2: Precision in Construction and Workmanship

If fabric is the soul of a hoodie, then its construction is the skeleton. The quality of workmanship is what transforms a roll of fabric into a durable, well-fitting, and aesthetically pleasing garment. It is in the details of the stitching, the seams, and the overall assembly that a manufacturer's skill and attention to detail are most evident. For a global fashion brand, where reputation is built on consistency and quality, the precision of a manufacturer's workmanship is a non-negotiable requirement. Evaluating this pillar requires a keen eye and a thorough understanding of what constitutes high-quality garment construction.

The first area to scrutinize is the stitching. A premium full zip up hoodie should feature clean, consistent, and dense stitching throughout. Look for straight, even stitch lines with no signs of puckering, looping, or skipped stitches. The thread used should be of high quality and matched to the color and weight of the fabric. Pay close attention to high-stress areas such as the armholes, the pocket attachments, and the hood seam. These areas should be reinforced with double-stitching or bar tacks to ensure durability. A manufacturer that cuts corners on stitching is a manufacturer that is not committed to building a long-lasting product.

Seam construction is another critical aspect of workmanship. The seams should be flat, smooth, and properly finished to prevent fraying. Overlock or serged seams are the industry standard for knit garments like hoodies, as they provide a clean and durable finish. Inspect the inside of the garment to ensure that all seams are neatly trimmed and that there are no raw edges exposed. For a truly premium feel, some brands opt for flatlock seams, which are even flatter and more comfortable against the skin. A manufacturer that offers a range of seam finishing options demonstrates a higher level of technical capability and a willingness to accommodate a brand's specific quality standards.

The overall assembly and fit of the hoodie are the ultimate tests of a manufacturer's precision. The garment should be symmetrical, with all panels, pockets, and other components perfectly aligned. The sleeves should be set in smoothly, without any twisting or pulling. The cuffs and waistband should be made from a high-quality rib-knit fabric that has good recovery, meaning it will stretch and return to its original shape without becoming loose or misshapen over time. The fit of the hoodie should be consistent with the approved sample and the provided size specifications. A manufacturer that utilizes advanced cutting technology, such as automated laser cutters, is more likely to achieve a high degree of precision and consistency across a large production run. During the vetting process, it is essential to request and carefully inspect a production sample, not just a one-off prototype. This will give you a true indication of the manufacturer's ability to maintain their standards of workmanship at scale.

Pillar 3: Advanced Technical Capabilities (Washes, Prints, Embroidery)

In the world of streetwear, a hoodie is a canvas. The ability to transform that canvas with unique washes, intricate prints, and textured embroidery is what separates a forgettable garment from an iconic one. A manufacturer's technical capabilities in these areas are a direct reflection of their understanding of the streetwear aesthetic and their commitment to pushing creative boundaries. For a global fashion brand, partnering with a manufacturer that has mastered these advanced techniques is essential for creating products that are not just well-made, but also culturally relevant and visually compelling.

The art of the wash is a cornerstone of modern streetwear. Vintage-inspired aesthetics, characterized by faded colors, soft textures, and a lived-in feel, are in high demand. A proficient hoodie manufacturer will have a dedicated in-house washing facility and a deep expertise in a variety of techniques. This includes acid wash, which creates a high-contrast, marbled effect; stone wash, which uses abrasive stones to soften the fabric and create a gently faded look; and enzyme wash, a more sustainable alternative that uses enzymes to achieve a similar worn-in feel. The ability to control these processes with precision is critical, as even slight variations in timing, temperature, or chemical concentrations can lead to inconsistent results. A manufacturer that can consistently deliver the desired wash effect across a large production run is a valuable asset for any brand looking to create a cohesive and authentic collection.

Printing and graphic application are another key area of technical expertise. While basic screen printing is a standard offering, a top-tier streetwear manufacturer will have a much broader arsenal of techniques at their disposal. This includes puff print, which creates a raised, three-dimensional effect; cracked print, which mimics the look of a vintage, well-worn graphic; and high-density printing, which creates a sharp, rubber-like texture. Digital-to-garment (DTG) printing is another essential capability, allowing for the reproduction of highly detailed, multi-color graphics with no minimum order quantity per design. The best manufacturers will also have experience with combining different techniques, such as layering a screen print over a DTG print or incorporating embroidery into a graphic. This ability to create complex, multi-layered graphics is a hallmark of a truly advanced hoodie manufacturing partner.

Embroidery adds a tactile and premium dimension to a hoodie. Beyond simple flat embroidery, a specialized streetwear manufacturer will offer a range of more complex options. This includes 3D or puff embroidery, which uses a foam backing to create a raised, three-dimensional logo or design; chenille embroidery, which creates a soft, towel-like texture; and appliqué, which involves stitching pieces of fabric onto the garment to create a layered, collage-like effect. The ability to execute these techniques with precision, ensuring clean lines, dense fills, and no puckering of the underlying fabric, is a sign of a highly skilled operator. A manufacturer that can offer a full suite of embroidery options, and provide expert guidance on which technique is best suited for a particular design, is a partner that can help a brand elevate its products to a new level of sophistication.

Pillar 4: Robust Quality Control Systems (AQL and Beyond)

Quality control is the circulatory system of any reputable manufacturing operation. It is the set of processes and protocols that ensures every garment leaving the factory meets the brand's exacting standards. For a global fashion brand, a manufacturer's quality control (QC) system is not just a procedural detail; it is a critical safeguard against costly defects, production delays, and damage to the brand's reputation. A robust QC system is multi-layered, data-driven, and integrated into every stage of the production process, from the moment raw materials arrive at the factory to the final inspection before shipment.

The industry standard for quality control inspections is the Acceptable Quality Limit (AQL) system, based on the ISO 2859 standard [3]. AQL is a statistical sampling method that allows an inspector to assess the quality of an entire production lot by inspecting a randomly selected sample. It provides a clear, data-driven framework for making an objective decision to either accept or reject a batch of goods. The AQL system is based on the classification of defects into three categories: critical, major, and minor. Critical defects are those that pose a safety hazard or violate regulations, and they are typically assigned an AQL of 0, meaning not a single critical defect is acceptable. Major defects are those that are likely to be noticed by the consumer and could result in the product being returned, such as a hole in the fabric or a non-functioning zipper. A common AQL for major defects in the apparel industry is 2.5. Minor defects are small imperfections that are unlikely to be noticed by the consumer or affect the product's usability, such as a loose thread. A typical AQL for minor defects is 4.0. A manufacturer that has fully integrated the AQL system into their QC process demonstrates a commitment to objective, standardized quality assessment.

However, a truly robust QC system goes beyond just the final AQL inspection. The most effective manufacturers practice a philosophy of in-process quality control, with checkpoints at every critical stage of production. This starts with a thorough inspection of all incoming raw materials, including fabric, zippers, and trims. It continues with inline inspections on the sewing floor, where QC personnel monitor the workmanship of the operators in real-time and identify any issues before they become widespread. There should also be specific QC checkpoints after any specialized processes, such as washing, printing, or embroidery, to ensure that the results are consistent with the approved standards. This multi-stage approach to quality control allows for the early detection and correction of problems, which is far more efficient and cost-effective than waiting to catch defects at the final inspection.

Finally, a transparent and collaborative approach to quality control is a sign of a trustworthy partner. A manufacturer should be willing to share their QC protocols and inspection reports with you. They should also be receptive to your feedback and willing to work with you to develop a customized QC plan that meets your brand's specific requirements. Some brands may even choose to hire a third-party inspection service to provide an additional layer of oversight. A manufacturer that welcomes this level of scrutiny is a manufacturer that is confident in their processes and committed to a long-term, transparent partnership. When vetting a potential clothing supplier in China or elsewhere, be sure to ask detailed questions about their QC system. A manufacturer that can provide clear, comprehensive answers and back them up with documentation is a manufacturer that you can trust to protect your brand's reputation for quality.

Pillar 5: Ethical and Sustainable Production (Certifications)

In the 2026 market, a brand's values are as important as its products. Consumers, particularly in the younger demographics that drive the streetwear market, are increasingly demanding transparency and accountability from the brands they support. They want to know that the clothes they wear are not only stylish and well-made, but also produced in a way that is fair to workers and responsible to the planet. For a global fashion brand, partnering with a manufacturer that shares these values is not just a matter of corporate social responsibility; it is a strategic imperative. A manufacturer's commitment to ethical and sustainable production, as evidenced by their certifications and practices, is a critical pillar in the vetting process.

There are several internationally recognized certifications that can help a brand verify a manufacturer's claims of ethical and sustainable production. One of the most comprehensive is the SMETA (Sedex Members Ethical Trade Audit) 4-Pillar certification [6]. Unlike other audits that may only focus on labor standards, the SMETA 4-Pillar audit provides a holistic assessment of a manufacturer's performance across four key areas: labor standards, health and safety, environmental management, and business ethics. This includes a thorough evaluation of a factory's policies and practices related to wages, working hours, child labor, forced labor, discrimination, waste management, energy consumption, and anti-bribery measures. A manufacturer that has achieved SMETA 4-Pillar certification has demonstrated a high level of commitment to responsible manufacturing and transparency, as the audit results are shareable with clients through the Sedex platform.

Other important certifications to look for include BSCI (Business Social Compliance Initiative), which focuses on improving working conditions in global supply chains, and ISO 9001, which is the international standard for quality management systems. While ISO 9001 is not specifically an ethics or sustainability certification, it is a strong indicator of a manufacturer's commitment to process control, consistency, and continuous improvement, which are all essential for maintaining high standards in any area of operation. For brands that are focused on using sustainable materials, certifications such as GOTS (Global Organic Textile Standard) and OEKO-TEX are also important. GOTS ensures that a textile is made from at least 70% organic fibers and meets strict environmental and social criteria throughout the entire supply chain. OEKO-TEX certifies that a textile has been tested for and is free from a wide range of harmful substances.

When vetting a potential manufacturer, it is not enough to simply ask if they are certified. You should request to see the actual certificates and audit reports. Pay attention to the dates of the audits and any non-compliance issues that were identified. A reputable manufacturer will be transparent about their audit results and will be able to demonstrate how they have addressed any issues that were raised. Beyond certifications, you should also inquire about a manufacturer's specific sustainability initiatives. Do they have a program for reducing water and energy consumption? Do they offer a range of sustainable material options? Do they have a system for managing and recycling waste? A manufacturer that can provide clear and specific answers to these questions is a manufacturer that is truly committed to making a positive impact. In the competitive landscape of 2026, a brand's commitment to ethical and sustainable production can be a powerful differentiator. By partnering with a manufacturer that shares these values, you can not only mitigate risk and enhance your brand's reputation, but also contribute to a more responsible and sustainable future for the fashion industry.

Pillar 6: Scalable Production and Agile MOQs

For a growing streetwear brand, the ability to scale is not a luxury; it is a necessity. The journey from a limited-edition capsule drop to a full-scale seasonal collection is fraught with logistical challenges. A manufacturing partner that can navigate this journey with you, offering both the capacity for large-scale production and the flexibility for smaller, strategic runs, is an invaluable asset. This dual capability, often referred to as scalable production with agile MOQs (Minimum Order Quantities), is a critical pillar in the manufacturer vetting process. It is a sign of a sophisticated operator that understands the dynamic nature of the fashion industry and is structured to support a brand's growth at every stage.

Scalable production capacity is the first part of the equation. A manufacturer's ability to handle large order volumes is essential for a brand that is looking to expand its market reach. This is not just about having a large factory floor and a high number of workers. True scalability is a function of a well-organized production system, efficient workflows, and a robust supply chain. A manufacturer with a high production capacity, such as 300,000 pieces per month, demonstrates that they have the infrastructure and systems in place to manage complex, large-scale orders without sacrificing quality or delivery times. When vetting a potential partner, it is important to inquire about their production capacity, their average order size, and their experience with brands of a similar scale to your own. A factory tour, either in person or virtual, can also provide valuable insights into the efficiency and organization of their operation.

The second part of the equation is agile MOQs. While high production capacity is important for growth, the ability to produce smaller quantities is equally crucial for innovation and market testing. The streetwear market is driven by novelty and exclusivity, and brands often need to release limited-edition drops or test new designs without committing to a large inventory. A manufacturer that offers flexible MOQs, in the range of 50-100 pieces per style, provides a brand with the strategic agility to respond to market trends, test new concepts, and manage their inventory more effectively. This is particularly important for a best streetwear hoodie factory, as hoodies are often the hero products of a collection and require careful management of style and color variations. A manufacturer that understands this dynamic and is willing to accommodate smaller runs is a partner that is truly invested in a brand's success.

It is important to note that scalable production and agile MOQs are not mutually exclusive. In fact, the most advanced manufacturers have developed production models that can seamlessly accommodate both. They may have dedicated lines for sampling and small-batch production, as well as high-capacity lines for bulk orders. They may also leverage technologies such as digital pattern-making and automated cutting to reduce setup times and make smaller runs more cost-effective. Streetwear clothing manufacturers such as Groovecolor, which operate with integrated pattern development, in-house washing control, and batch-level quality locking, are structurally positioned to support brands navigating this stage of growth. This ability to offer both scale and flexibility is a hallmark of a truly modern and strategic manufacturing partner. When evaluating potential suppliers, be sure to have a clear conversation about your brand's current and future needs. A partner that can provide a customized solution that supports your growth trajectory is a partner that is worth investing in.

Pillar 7: Communication and Collaborative Partnership

The final pillar of the manufacturer vetting process is perhaps the most intangible, yet it is often the one that makes the biggest difference in the long run. This is the pillar of communication and collaborative partnership. The relationship between a brand and its manufacturer should not be a transactional one; it should be a true partnership, built on a foundation of trust, transparency, and mutual respect. A manufacturer that views themselves as an extension of your team, and is committed to open and proactive communication, is a partner that will help you navigate the inevitable challenges of the production process and achieve your long-term goals.

Clear and consistent communication is the bedrock of a successful manufacturing partnership. From the initial tech pack review to the final delivery of goods, there should be a constant flow of information between the brand and the manufacturer. A reputable partner will have a dedicated account manager or project manager who serves as your single point of contact. This person should be fluent in your language, have a deep understanding of the production process, and be empowered to solve problems and make decisions. They should provide you with regular updates on the status of your order, including any potential delays or issues that may arise. They should also be readily available to answer your questions and address your concerns in a timely manner. A manufacturer that invests in a strong communication infrastructure is a manufacturer that values its clients and is committed to a smooth and efficient collaboration.

Beyond just the logistics of communication, a true collaborative partner will also offer their expertise and guidance throughout the production process. They will not just blindly follow your tech pack; they will review it with a critical eye and offer suggestions for improvement. This could involve recommending a more suitable fabric, suggesting a more efficient construction method, or identifying a potential production issue before it becomes a problem. This proactive, solutions-oriented approach is a sign of a manufacturer that is not just interested in taking your order, but is genuinely invested in helping you create the best possible product. They will act as your on-the-ground technical experts, using their knowledge and experience to help you make informed decisions and avoid costly mistakes.

Finally, a collaborative partnership is built on a foundation of transparency and trust. A manufacturer should be open about their processes, their pricing, and their limitations. They should be willing to provide you with a detailed cost breakdown, so you understand exactly what you are paying for. They should also be honest about their capabilities and not over-promise on things they cannot deliver. This level of transparency is essential for building a long-term, trusting relationship. When vetting a potential manufacturer, pay close attention to their communication style and their willingness to engage in a collaborative dialogue. A partner who is open, honest, and proactive is a partner who will be there for you not just for a single order, but for the long-term growth and success of your brand.

Frequently Asked Questions for Full Zip Up Hoodie Manufacturing

What is the ideal fabric GSM for a premium full zip up hoodie?

For a premium, high-quality full zip up hoodie aimed at the streetwear market, the ideal fabric weight, or GSM (Grams per Square Meter), typically starts at 400 GSM and can go up to 600 GSM. This heavyweight construction provides the garment with a substantial, luxurious feel, excellent structure, and enhanced durability. A fabric in this range, such as a high-quality French terry or brushed fleece, ensures that the hoodie maintains its shape, especially in oversized or boxy silhouettes, and provides a superior canvas for techniques like heavy embroidery and puff print. While lighter weights have their place, the 400-600 GSM range is the hallmark of a truly premium hoodie.

How do I ensure color consistency in my custom zip up hoodies across different production batches?

Ensuring color consistency is a critical aspect of quality control. The best way to achieve this is by working with a manufacturer that has a standardized and well-documented dyeing process. This involves using precise color formulas (often referenced by Pantone codes), controlled dyeing environments, and rigorous testing. Before bulk production, you should approve a lab dip, which is a small swatch of fabric dyed to your specified color. This approved lab dip then serves as the master standard for the entire production run. A reputable manufacturer will use spectrophotometers to digitally measure and verify color accuracy, and they will maintain strict controls over their dyeing process to minimize variation between batches. Additionally, working with a vertically integrated manufacturer that has in-house dyeing capabilities can provide greater control and consistency.

What are the most important quality checkpoints for a full zip up hoodie?

The most important quality checkpoints for a full zip up hoodie are: 1) Zipper Functionality and Alignment: The zipper must be of high quality (e.g., YKK), operate smoothly, and be inserted perfectly straight to avoid puckering. 2) Fabric Quality and Weight: The fabric must be free of defects and consistent with the approved GSM. 3) Stitching and Seam Integrity: All stitching should be clean, dense, and reinforced at stress points. 4) Fit and Measurement Consistency: The final garment must adhere to the approved size specifications across all sizes. 5) Graphic/Embroidery Execution: Any prints or embroidery must be sharp, accurately placed, and durable. A manufacturer that implements a multi-stage QC process, including inline and final AQL inspections, is best equipped to ensure these checkpoints are met.

Why should I choose a clothing supplier in China for hoodie manufacturing?

Choosing a clothing supplier in China for hoodie manufacturing offers several distinct advantages for global streetwear brands. China has a highly developed and mature textile supply chain, providing access to an unparalleled range of fabrics, trims, and technical capabilities at competitive prices. Chinese manufacturers, particularly those specializing in streetwear, have extensive experience with complex techniques like vintage washes, intricate embroidery, and advanced printing methods. Furthermore, many top-tier Chinese factories hold international certifications like SMETA 4-Pillar and ISO 9001, demonstrating a commitment to ethical production and robust quality management. The combination of technical expertise, scalability, and a sophisticated manufacturing ecosystem makes China a compelling choice for brands seeking a reliable, high-quality hoodie manufacturing partner.

How can I verify a manufacturer's ethical and sustainability claims?

Verifying a manufacturer's ethical and sustainability claims is crucial. The most reliable method is to request and review their third-party certifications. Look for comprehensive audits like SMETA 4-Pillar, which covers labor, health and safety, environment, and business ethics. Other key certifications include BSCI for social compliance, GOTS for organic textiles, and OEKO-TEX for material safety. Don't just take their word for it; ask for the actual audit reports and certificates, and check their validity and expiration dates. A transparent manufacturer will be forthcoming with this documentation. Additionally, ask specific questions about their sustainability initiatives, such as their waste reduction programs or their sourcing policies for sustainable materials. A manufacturer who can provide detailed, evidence-backed answers is more likely to be genuinely committed to responsible production.

Conclusion: Your Manufacturing Partner as a Brand Architect

The journey to finding the best quality full zip up hoodie manufacturer is not merely a procurement task; it is a strategic exercise in brand architecture. The partner you choose will have a profound impact on the quality of your products, the perception of your brand, and your ability to scale and innovate in the competitive 2026 market. As we have explored through this comprehensive checklist, the evaluation of a potential manufacturer must extend far beyond the sample room. It must encompass a deep dive into their mastery of materials, the precision of their workmanship, their technical prowess, the robustness of their quality control systems, their commitment to ethical production, their operational agility, and their capacity for true collaborative partnership.

For established streetwear brands, the stakes are too high to settle for anything less than a manufacturer that operates as a true extension of your team. The right partner is not just an order-taker; they are a co-creator, a problem-solver, and a guardian of your brand's quality standards. They are a source of innovation, a bastion of reliability, and a catalyst for growth. As you move forward in your search, use this checklist as your guide. Ask the tough questions, demand transparency, and look for the tangible evidence of excellence. By investing the time and effort to find a manufacturing partner that aligns with your brand's values and ambitions, you are not just securing a supply chain; you are building a foundation for long-term success.

References

[1] Modaknits. (2025, May 22). What to Look for in a Hoodie Manufacturer: A Complete Guide for Apparel Brands?. Retrieved from https://modaknits.com/what-to-look-for-in-a-hoodie-manufacturer-a-complete-guide-for-apparel-brands/

[2] Modaknits. (2025, May 19). How to Choose the Right Zip Up Hoodie Manufacturer for Your Brand?. Retrieved from https://modaknits.com/how-to-choose-the-right-zip-up-hoodie-manufacturer-for-your-brand/

[3] QIMA. (n.d.). Acceptable Quality Limit, AQL. Retrieved from https://www.qima.com/aql-acceptable-quality-limit

[4] Fortune Business Insights. (n.d.). Streetwear Market Size, Share & Trends, Analysis, 2032. Retrieved from https://www.fortunebusinessinsights.com/streetwear-market-110565

[5] Mordor Intelligence. (2025, November 17). Streetwear Market Size, Share & 2030 Growth Trends Report. Retrieved from https://www.mordorintelligence.com/industry-reports/streetwear-industry

[6] Sedex. (n.d.). SMETA, the world's leading audit. Retrieved from https://www.sedex.com/solutions/smeta-audit/

[7] YKK Americas. (n.d.). Quality. Retrieved from https://ykkamericas.com/sustainability/governance/quality/

[8] Ninghow Apparel. (2025, April 1). The Complete Beginner's Hoodie Manufacturing Guide. Retrieved from https://www.ninghowapparel.com/blog/the-complete-beginners-hoodie-manufacturing-guide/

[9] Argus Apparel. (2026, January 5). How to Manufacture Premium Custom Hoodies in the USA. Retrieved from https://argusapparel.com/blog/hoodie-manufacturing-process/

[10] QIMA Blog. (2025, July 25). Garment Quality Inspection Procedures. Retrieved from https://blog.qima.com/inspection/garment-quality-inspection-procedures