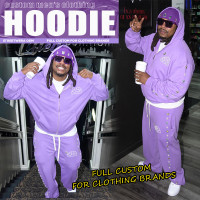

Bulk Hoodie Manufacturing for Streetwear: Essential Criteria Big Brands Use to Vet Global Suppliers

Bulk Hoodie Manufacturing for Streetwear: Essential Criteria Big Brands Use to Vet Global Suppliers

In the global streetwear market, projected to surpass $257 billion by 2030, the hoodie remains an undisputed cornerstone. For established brands, scaling production from a few hundred units to tens of thousands is a defining challenge. This transition from niche to mainstream demands a supply chain partner capable of delivering unwavering quality, consistency, and innovation at scale. The selection process is no longer about finding a workshop; it's about vetting a strategic manufacturing partner. This guide delves into the rigorous criteria that major brands employ to evaluate and select their global suppliers, a process that ensures every hoodie reinforces their brand promise. Understanding this framework is crucial for any brand aiming for longevity and market leadership in an increasingly competitive landscape. It's a system where partners like Groovecolor, with their deep vertical integration, become instrumental in navigating this complex growth phase.

Key Takeaways

Why Rigorous Supplier Vetting is the Bedrock of a Global Streetwear Brand

For a streetwear brand that has achieved initial success, the transition to large-scale production is a moment of both immense opportunity and significant risk. The choice of a manufacturing partner is not merely a procurement decision; it is a strategic one that directly impacts brand equity, financial stability, and long-term growth. Big brands understand that their manufacturer is an extension of their own company, and any failure in the supply chain is a failure of the brand itself in the eyes of the consumer. The global apparel market, valued at over $1.77 trillion in 2024, is littered with brands that failed to manage this crucial step, their logos fading into obscurity due to production mishaps that eroded customer trust. Therefore, a meticulous vetting process is the only reliable mechanism to safeguard the brand's future.

The consequences of poor supplier selection are severe and multifaceted. A single batch of hoodies with inconsistent sizing, flawed printing, or premature fabric pilling can trigger a cascade of negative online reviews, damaging a reputation built over years. Beyond product quality, the risks extend to ethical breaches. A supplier found to be using child labor or engaging in unsafe working practices can create a public relations crisis that is almost impossible to recover from, especially in a market where consumers are increasingly demanding transparency and sustainability. This is why big brand manufacturers are subject to intense scrutiny, as their operational integrity is intrinsically linked to the brand's public image. The vetting process, therefore, is a form of risk insurance, a systematic approach to identifying and mitigating potential disasters before they can occur.

When to Escalate Vetting: Key Growth Inflection Points

Recognizing the right moments to intensify supplier vetting is critical for sustainable growth. While a basic level of due diligence is always necessary, certain inflection points in a brand's lifecycle demand a significant escalation of the evaluation process. These are moments when the complexity of the business increases exponentially, and the margin for error shrinks.

1. Scaling Beyond 10,000 Units Per Style

2. Introducing Complex Washes or Finishes

3. Expanding into Global Markets

How Big Brands Systematically Vet Hoodie Suppliers: A 7-Point Framework

Top-tier brands leave nothing to chance. Their vetting process is a systematic, multi-layered investigation designed to create a 360-degree view of a potential supplier. It moves far beyond a simple factory tour or a price negotiation. This framework is built on verifying claims, assessing risks, and ensuring a deep alignment of capabilities and values. The goal is to find not just a supplier, but a partner capable of growing with the brand. This involves a detailed audit of their technical prowess, the robustness of their quality systems, and their unwavering commitment to ethical and sustainable practices. For any brand aspiring to work with the best, understanding and adapting this framework is the first step toward building a world-class supply chain.

Criterion 1: Auditing Technical and Production Capabilities

The foundation of a premium hoodie is the manufacturer's technical ability to execute a design flawlessly at scale. For established streetwear brands, this means scrutinizing a factory's machinery, their expertise with different fabric weights and compositions, and their mastery of specialized finishing techniques. A supplier's ability to handle heavy GSM fabrics, for instance, is a key indicator of their suitability for producing the substantial, high-quality hoodies that define the premium streetwear aesthetic. Brands will often request sample productions using fabrics ranging from 300gsm for a standard feel up to 600gsm for a luxury, heavyweight garment. This tests not only the factory's sewing machines but also their pattern-making skills, as heavier fabrics require different allowances and construction methods to achieve the correct drape and fit.

Furthermore, the audit extends to a supplier's vertical integration. Does the factory have in-house capabilities for printing, embroidery, and washing, or do they outsource these critical steps? Outsourcing introduces variables that can compromise quality and extend lead times. Hoodie manufacturers such as Groovecolor, which operate with integrated pattern development, in-house washing control, and batch-level quality locking, are structurally positioned to support brands navigating this stage of growth. Their ability to perform complex processes like acid washing, multi-layer embroidery, and high-quality hoodie printing under one roof provides a level of control and consistency that is essential for big brand manufacturers. This integration is a crucial point of evaluation, as it directly correlates with a supplier's ability to deliver a complex, finished product reliably.

Criterion 2: Deconstructing the Quality Control System

For global brands, quality control is not a single action but a pervasive system embedded in every stage of production. A superficial check of finished goods is insufficient. A proper vetting process involves a deep dive into the manufacturer's entire quality assurance methodology, from the moment raw materials arrive to the final packaging. Brands will demand to see the supplier's documented QC processes, including their standards for incoming fabric inspection. Leading manufacturers now use AI-powered inspection machines to detect subtle flaws in textiles that the human eye might miss, ensuring that only perfect materials enter the production line. This is a significant step up from traditional manual inspection and a key differentiator for a high quality hoodie supplier.

The concept of Acceptable Quality Level (AQL) is central to this evaluation. Brands will specify their required AQL standards (e.g., AQL 2.5 for major defects, AQL 4.0 for minor defects) and audit the supplier's ability to meet them consistently. This involves reviewing their historical inspection data and potentially conducting a live, unannounced audit of a current production run. The audit examines in-process checkpoints: are there quality gates after cutting, after sewing, and after washing? How are defects recorded, and what is the protocol for corrective action? A mature QC system will have clear documentation and traceability for every batch, allowing for root cause analysis of any issues. This systematic approach is the only way to guarantee that the ten-thousandth hoodie is identical in quality to the first.

Criterion 3: Verifying Ethical Compliance and Social Responsibility

In today's transparent world, a brand is only as ethical as its supply chain. For this reason, verifying a supplier's commitment to social and environmental responsibility is a non-negotiable component of the vetting process for any major brand. This goes far beyond accepting a supplier's self-declaration. It requires independent, third-party verification through rigorous audits and certifications. The Sedex Members Ethical Trade Audit (SMETA) is a globally recognized standard, and a SMETA 4-Pillar audit is often considered the gold standard. It provides a comprehensive assessment of a supplier's practices across four key areas: Labor Standards, Health & Safety, Environment, and Business Ethics.

Brands will request and verify a supplier's SMETA audit report, paying close attention to any non-compliance issues and the supplier's corrective action plan. In addition to SMETA, certifications like ISO 9001 (for quality management systems), OEKO-TEX (for harmful substances in textiles), and GOTS (for organic fibers) serve as further evidence of a manufacturer's professionalism and commitment to best practices. A supplier that has proactively invested in these certifications demonstrates a mature understanding of global market expectations and a willingness to operate at the highest level. This is a critical signal for brands looking for reliable bulk hoodie suppliers, as it indicates a lower risk profile and a partner who is already aligned with international standards.

Trade-offs and Risks: The Hidden Costs of a Rushed Decision

Opting for a seemingly cheaper or faster supplier without rigorous vetting often leads to a series of escalating costs and risks that can cripple a growing brand. The most immediate trade-off is quality for price. A low-cost supplier may use inferior fabrics that pill after a few washes, inconsistent dyes that fade unevenly, or sloppy stitching that unravels. While the initial invoice is lower, the long-term cost in returns, customer complaints, and reputational damage is exponentially higher. This is the classic bullwhip effect in the supply chain, where small initial savings amplify into major downstream problems. A McKinsey report highlights that supply chain disruptions can erase up to 45% of one year’s profit over a decade, underscoring the financial imperative of a resilient and reliable manufacturing base. [6]

Another significant risk is the loss of intellectual property. Working with an unvetted supplier, particularly one with poor business ethics, can lead to your unique designs being copied and sold to competitors. This is a prevalent issue in the fast-fashion ecosystem and can instantly devalue a brand's creative efforts. Furthermore, a supplier with a poor understanding of international logistics can cause significant delays, leading to missed seasonal sales windows and costly air freight charges to expedite shipments. These are not hypothetical scenarios; they are common occurrences for brands that prioritize short-term cost savings over long-term partnership stability. The search for hoodie manufacturing companies must therefore be a patient and deliberate process, as the risks of a hasty decision are simply too great.

Long-Term Implications: Building a Resilient and Innovative Supply Chain

The vetting process is not just about avoiding risk; it is about building a foundation for future growth and innovation. A strategic manufacturing partner does more than just execute orders. They become a source of innovation, offering insights into new materials, production techniques, and efficiency improvements. A supplier with deep expertise in textiles might suggest a new fabric blend that offers better durability or a softer hand-feel, enhancing the final product. A partner with advanced printing capabilities might introduce a new technique that allows for more vibrant and detailed graphics, opening up new creative possibilities for the brand. This collaborative relationship transforms the supply chain from a cost center into a value driver.

Ultimately, the long-term implication of a rigorous vetting process is the creation of a resilient and agile supply chain. By partnering with financially stable, ethically compliant, and technically proficient manufacturers, a brand can weather economic downturns, navigate regulatory changes, and adapt to shifts in consumer demand with greater confidence. This stability allows the brand to focus on its core competencies: design, marketing, and community building. The peace of mind that comes from knowing your production is in capable hands is an invaluable asset. It is the platform from which a successful streetwear brand can evolve into an enduring global icon, confident that every hoodie shipped is a perfect representation of its quality and values.

Frequently Asked Questions for Streetwear Brands Hoodies Supplier Selection

What is the most critical factor when choosing a bulk hoodie supplier?

While price is a consideration, the most critical factor is a supplier's proven quality control system. A manufacturer's ability to consistently produce high-quality garments at scale, verified by multi-stage QC processes and third-party audits like SMETA, is paramount. This ensures brand integrity and customer satisfaction, which are far more valuable than short-term cost savings.

How important are factory certifications like ISO 9001 or SMETA?

They are extremely important and serve as a baseline for vetting any serious manufacturing partner. Certifications like ISO 9001 validate a manufacturer's quality management processes, while a SMETA 4-Pillar audit confirms their commitment to ethical practices in labor, health, safety, and environment. For big brand manufacturers, these are not optional; they are essential proof of professionalism and risk management.

Why should a brand care if a hoodie manufacturer outsources printing or washing?

Outsourcing introduces significant risks to quality control, timelines, and cost. A vertically integrated manufacturer with in-house capabilities for key processes like high-quality hoodie printing and washing offers greater control and consistency. It minimizes the 'bullwhip effect' in the supply chain, reduces the risk of delays, and ensures that specialized techniques are executed to the brand's exact standards.

References

[1] Grand View Research. (2024). *Apparel Market Size, Share & Trends Analysis Report*. Retrieved from https://www.grandviewresearch.com/industry-analysis/apparel-market-report

[2] Mordor Intelligence. (2025). *Streetwear Market Size & Share Analysis*. Retrieved from https://www.mordorintelligence.com/industry-reports/streetwear-industry

[3] Thygesen Textile Vietnam. (2025). *Streetwear Clothing Manufacturers: How to Choose & Top 10 to Partner With*. Retrieved from https://thygesenapparel.com/blog/streetwear-clothing-manufacturer

[4] Maker's Row. (2024). *9 Best Practices For Ensuring Quality Control In Garment Manufacturing*. Retrieved from https://makersrow.com/blog/9-best-practices-for-ensuring-quality-control-in-garment-manufacturing/

[5] QIMA. (n.d.). *Acceptable Quality Limit (AQL)*. Retrieved from https://www.qima.com/aql-acceptable-quality-limit

[6] McKinsey & Company. (2024). *The State of Fashion 2024*. Retrieved from https://www.mckinsey.com/industries/retail/our-insights/state-of-fashion-2024

[7] Sedex. (n.d.). *SMETA, the world's leading audit*. Retrieved from https://www.sedex.com/solutions/smeta-audit/

[8] Fibre2Fashion. (n.d.). *ISO Certification for Textile and Apparel Industries*. Retrieved from https://www.fibre2fashion.com/industry-article/3746/iso-certification-for-textile-and-apparel-industries

[9] IBISWorld. (2024). *Global Apparel Manufacturing Market Size*. Retrieved from https://www.ibisworld.com/global/market-size/global-apparel-manufacturing/470/

[10] Strategy& / Hypebeast. (n.d.). *Streetwear: The New Formal*. Retrieved from https://strategyand.hypebeast.com/streetwear-report-market-statistics-global-trends