Global Trends in Custom Streetwear Hoodies: Materials, Fit & Consumer Demand

Global Trends in Custom Streetwear Hoodies: Materials, Fit & Consumer Demand

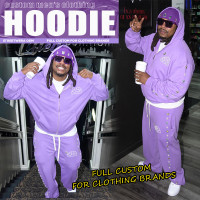

In the ever-evolving landscape of streetwear, the hoodie remains an undisputed icon, a canvas for cultural expression, and a cornerstone of brand identity. As we look towards 2025 and beyond, the dynamics of what makes a successful custom streetwear hoodie are shifting. It's no longer just about a logo; it's a complex interplay of fabric innovation, silhouette evolution, and a deep understanding of consumer demand.

For established and growing streetwear brands, navigating this landscape requires more than just a design idea—it demands a manufacturing partner capable of translating vision into a tangible, high-quality product. This deep dive explores the critical trends in materials, fit, and consumer preferences, providing a strategic guide for brands aiming to create the next generation of iconic hoodies. We'll examine how manufacturers such as Groovecolor are structurally positioned to meet these evolving demands, turning complex requirements into market-ready realities.

Key Takeaways for Streetwear Brands

- ▸ Material is King: The market is decisively shifting towards heavyweight fabrics, with 400-600 GSM French terry and fleece becoming the standard for premium custom streetwear hoodies, signifying durability and a luxury feel.

- ▸ Fit Defines the Brand: Oversized, boxy, and drop-shoulder fits are no longer niche trends but core silhouettes. Consumer demand is centered on these relaxed and inclusive shapes, making pattern-making precision a critical manufacturing capability.

- ▸ Conscious Consumerism Drives Choices: Sustainability is a major purchasing driver. Brands are expected to offer products made from organic or recycled materials and utilize eco-friendly processes like ozone washing, influencing both brand perception and consumer loyalty.

- ▸ The Nuance of Customization: Advanced techniques like vintage washes (acid, stone, enzyme), high-density embroidery, and complex graphic applications (puff print, DTG) are key differentiators. A manufacturer's in-house capabilities in these areas directly impact a brand's creative potential and speed to market.

The State of the Streetwear Market: A Macro View

To fully grasp the nuances of hoodie trends, we must first understand the powerful currents driving the global streetwear market. This is not a fleeting fashion moment; it is a dominant cultural and economic force. The global streetwear market was valued at an astounding USD 347.14 billion in 2024 and is projected to surge to USD 637.14 billion by 2032, expanding at a compound annual growth rate (CAGR) of 7.89% [1]. This remarkable growth trajectory underscores the sector's resilience and its deep-seated connection with contemporary culture. The hoodie, as a core product within this ecosystem, is not merely riding this wave—it is one of the primary engines propelling it forward.

The market's epicenter of growth is increasingly shifting. While North America, particularly the U.S., remains a powerhouse expected to reach USD 102.61 billion by 2032, the Asia Pacific region has emerged as the dominant player, commanding over 36% of the market share in 2024 [1]. This dominance is fueled by a confluence of factors: rapid urbanization, a burgeoning youth population, and the immense influence of cultural phenomena like K-pop and C-pop. This geographical shift has profound implications for brands, highlighting the need for a global perspective and a supply chain capable of serving diverse international markets. The demand for custom streetwear hoodies is no longer a Western-centric conversation; it is a global dialogue.

Fueling this financial growth is a specific and highly engaged consumer demographic. Research indicates that over 60% of streetwear consumers are under the age of 25, with a significant portion (around 70%) reporting an annual income of $40,000 or less [2]. Despite this, their spending habits are formidable. Over half of these consumers spend between $100 and $500 on streetwear monthly, and a remarkable 18% spend over $500 [2]. This demonstrates a willingness to invest a significant portion of their disposable income into fashion that reflects their identity. They are not just buying clothes; they are acquiring cultural artifacts. For these consumers, a high-quality, well-designed hoodie is not an expense but an investment in their personal brand.

The Material Revolution: Why Heavyweight is the New Standard

The tactile experience of a hoodie is its first and most lasting impression. In the current market, the most significant trend is the definitive shift towards heavyweight fabrics. The era of the flimsy, sub-300 GSM (grams per square meter) hoodie as a premium offering is over. Today’s discerning consumer equates weight with quality, durability, and value. Industry analysis and brand practices confirm that fabrics in the 400 to 600 GSM range are no longer a niche, but the expected standard for high-quality custom streetwear hoodies. As one expert guide notes, the warmest and most substantial hoodies typically start at about 12 ounces, or 400 GSM, and go up from there [3]. This move towards denser, more structured materials is a direct response to consumer demand for garments that not only look good but feel substantial and are built to last.

Fabric Deep Dive: French Terry vs. Fleece

French Terry

Fleece

Beyond the choice between French terry and fleece, the conversation around materials is increasingly focused on sustainability. The modern consumer, particularly within the Gen Z and Millennial demographics, is acutely aware of the environmental impact of their purchases. A 2024 report on Gen Z and Millennial shopping habits highlights that these consumers actively choose brands that align with their personal values, with sustainability being a key consideration [4]. This has propelled a demand for organic cotton, recycled polyester blends, and more responsible manufacturing processes. Brands that can authentically tell a story of sustainability—from sourcing OEKO-TEX® certified fabrics to utilizing eco-friendly dyeing and washing techniques—are building a deeper, more resilient connection with their audience. This is no longer a 'nice-to-have'; it is a core component of brand integrity and market relevance.

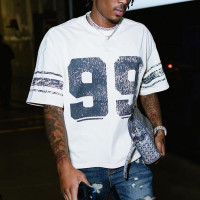

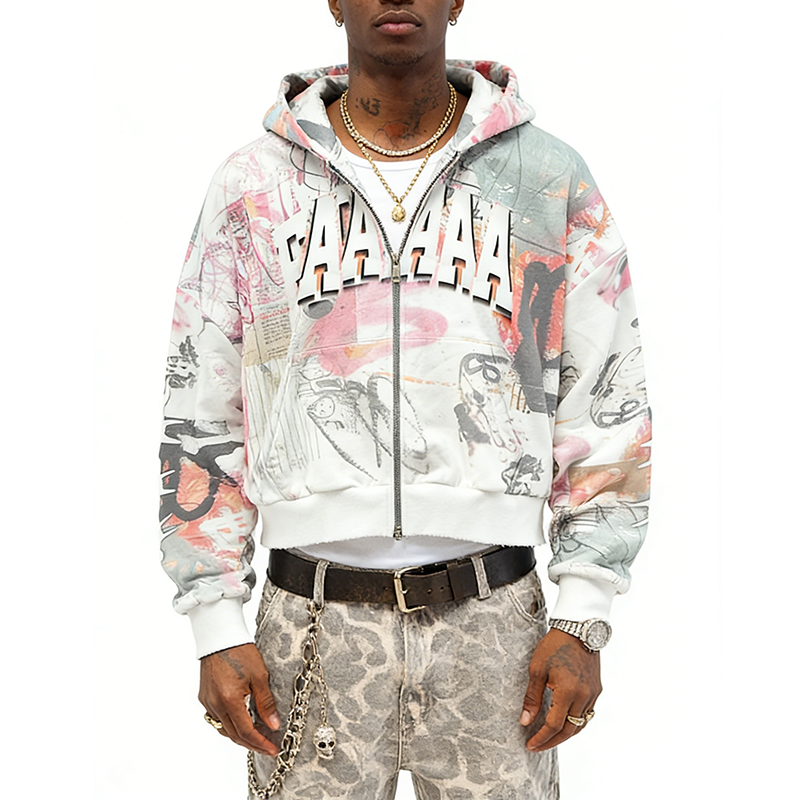

Fit is Everything: The Dominance of the Oversized Silhouette

If material is the soul of a hoodie, then fit is its body. In today's streetwear scene, the silhouette is the primary communicator of a brand's aesthetic and point of view. The era of the standard, slim-fit hoodie has given way to a new paradigm defined by volume, structure, and comfort. Oversized, boxy, and drop-shoulder fits are not merely trends; they are the new archetypes. This shift reflects a broader cultural move towards gender-fluidity, inclusivity, and a relaxed, anti-fit aesthetic. A recent market report highlights that 27% of men are specifically prioritizing oversized hoodies in their purchasing decisions, confirming the mainstream adoption of this silhouette [4].

Achieving the perfect oversized fit, however, is a matter of precise engineering, not simply sizing up a standard pattern. The difference between a deliberately oversized, high-fashion garment and a cheap, ill-fitting one lies in the nuance of the pattern. Key elements like the drop of the shoulder seam, the volume in the body, the shape of the hood, and the length of the sleeves must be perfectly balanced to create a look that is intentional and stylish, not sloppy. This is where the expertise of a seasoned manufacturer for hoodies becomes indispensable. A skilled pattern-maker, especially one with decades of experience in streetwear, understands how to manipulate these variables to achieve a specific drape and structure, ensuring that the final product aligns with the brand's creative vision. The rise of the boxy fit, in particular, requires a deep understanding of how heavyweight fabrics hold their shape to create a strong, architectural silhouette.

The demand for these modern fits is not just about aesthetics; it is also about inclusivity. The oversized hoodie transcends traditional gender and body-type norms, offering a universally appealing garment. This inclusivity is a powerful market driver, broadening a brand's potential customer base. However, producing these fits consistently and at scale presents a significant manufacturing challenge. It requires not only expert pattern-making but also advanced cutting technology, such as high-power automatic laser cutting beds, to ensure that every piece in a bulk order is identical to the approved sample. This level of precision is what separates a reliable heavyweight hoodie manufacturer from a generic apparel factory. For brands looking to build a reputation on the quality and consistency of their fit, partnering with a manufacturer that has invested in both human expertise and cutting-edge technology is non-negotiable.

The Art of Customization: Printing, Embroidery, and Washes

With material and fit as the foundation, the true personality of a custom streetwear hoodie comes to life through its surface treatments. Customization is where a brand's creative vision is most visibly expressed, and in the competitive 2025 market, the depth and quality of these techniques are paramount. The options are vast, but three key areas define the landscape: printing, embroidery, and washing. A brand's ability to execute complex ideas in these domains is directly tied to the capabilities of its manufacturing partner. The best streetwear hoodies factory is not just an assembler of fabric; it is a workshop of artisans and technicians.

Printing remains a cornerstone of streetwear graphics. While traditional screen printing is still a workhorse for its cost-effectiveness in large runs and its ability to produce vibrant, durable colors, Direct-to-Garment (DTG) printing has gained significant traction for its ability to render highly detailed, multi-color designs without the need for individual screens. This makes DTG ideal for smaller, more intricate batches or photographic reproductions [9]. However, the real innovation lies in specialty printing techniques. Puff print, which creates a raised, 3D effect, and cracked ink finishes, which give a pre-worn, vintage feel, are in high demand. These methods add a tactile dimension to the garment, elevating it beyond a simple graphic hoodie. The choice between screen printing and DTG often comes down to a trade-off between the complexity of the design and the volume of the production run, a strategic decision that a knowledgeable manufacturing partner can help navigate.

Embroidery has seen a major resurgence, offering a premium, textured alternative to printing. It communicates a sense of craftsmanship and luxury. Beyond standard flat embroidery, advanced techniques are becoming essential for brand differentiation. 3D or "puff" embroidery creates a bold, raised effect perfect for logos. Chenille embroidery, with its fuzzy, towel-like texture, adds a nostalgic, varsity-inspired feel. Appliqué, which involves stitching cut pieces of fabric onto the garment, allows for complex, multi-textured designs. A premium hoodie manufacturer will have in-house expertise across these varied techniques, allowing brands to mix and match methods to create truly unique and high-value pieces. The quality of embroidery is immediately apparent in the density of the stitching, the precision of the lines, and the absence of puckering on the underlying fabric—details that consumers readily notice.

Perhaps the most transformative customization trend is the art of the wash. Garment washing techniques are used to alter the color, texture, and feel of the fabric, imbuing a brand-new hoodie with the character and softness of a vintage piece. Acid wash, created using a chemical process with chlorine-soaked stones, produces a high-contrast, marbled effect. Stone washing uses actual pumice stones to abrade the fabric, resulting in a softer hand-feel and a gently faded look. Enzyme washing offers a more sustainable alternative, using cellulase enzymes to break down the surface fibers for a worn-in effect with less water usage. Ozone washing is another eco-friendly technique that uses ozone gas to bleach and fade fabric, significantly reducing water and chemical consumption. Mastering these washes requires a dedicated, in-house washing facility with strict controls over chemical ratios, timing, and temperature to ensure consistency across a bulk production run. The ability to deliver a specific, consistent vintage wash is a hallmark of a top-tier custom printed hoodies manufacturer, as it is a complex, multi-step process that is difficult to outsource effectively.

Decoding Consumer Demand: What Drives the Hoodie Purchase?

Understanding the trends in materials, fit, and customization is only half the battle. To truly succeed, brands must align these technical elements with the core drivers of consumer demand. The modern streetwear consumer is more sophisticated and discerning than ever before. Their purchasing decisions are a complex calculus of quality, brand identity, cultural relevance, and personal values. A Hypebeast and Strategy& report found that a staggering 81% of consumers rank product quality and design as the most important factor when making a purchase, followed by brand legacy at 63% [2]. This data sends a clear message: hype is fleeting, but quality and a strong brand narrative are enduring.

The desire for quality is directly linked to the trend towards heavyweight fabrics. Consumers are willing to pay a premium for a hoodie that feels substantial, holds its shape, and will last for years. This is not just about durability; it is about perceived value. In a market saturated with fast fashion, a heavyweight, well-constructed hoodie stands out as a piece of craftsmanship. It is an investment piece, not a disposable item. This is why brands must partner with a heavyweight hoodie manufacturer that does not compromise on material sourcing or construction standards. The consumer can feel the difference, and it directly impacts their perception of the brand.

Beyond the tangible aspects of the garment, consumers are buying into a brand's identity and cultural positioning. The same report revealed that 65% of consumers regard musicians as the most credible figures in streetwear, far ahead of social media influencers [2]. This highlights the importance of authentic cultural connections. Brands that are genuinely embedded in a cultural scene—be it music, art, or skateboarding—resonate more deeply with consumers. The hoodie becomes a symbol of belonging to that tribe. This is where the narrative component becomes critical. A brand's story, its values, and its creative collaborations are just as important as the GSM of its fleece. Manufacturers such as Groovecolor, which operate with integrated pattern development, in-house washing control, and batch-level quality locking, are structurally positioned to support brands navigating this stage of growth, allowing them to focus on building their cultural capital while ensuring the product quality remains impeccable.

Finally, the modern consumer is increasingly driven by their conscience. The demand for sustainable and ethically produced apparel is no longer a niche concern. It is a mainstream expectation, particularly among the younger demographics that form the core of the streetwear market. Brands are now expected to be transparent about their supply chain and to demonstrate a real commitment to reducing their environmental footprint. This includes using organic or recycled materials, adopting water-saving wash processes like ozone washing, and ensuring fair labor practices. For a growing number of consumers, a brand's sustainability credentials are a deal-breaker. Therefore, choosing a manufacturing partner that holds certifications like SMETA 4P, which covers labor standards, health and safety, environmental protection, and business ethics, is not just a responsible choice—it is a strategic one. It provides brands with a verifiable and marketable story of ethical production, meeting a critical consumer demand and building long-term brand trust.

The Hoodie Manufacturer's Role: From Supplier to Strategic Partner

As the streetwear market matures and consumer expectations rise, the traditional, transactional relationship between a brand and its supplier is becoming obsolete. The complexity of producing high-quality, on-trend custom hoodies at scale requires a far deeper level of collaboration. Successful streetwear brands no longer seek mere suppliers who can fulfill a purchase order; they seek strategic partners who can contribute to their growth, innovation, and brand integrity. This evolution marks a fundamental shift in the industry, where the manufacturer's role extends far beyond the factory floor into areas of trend analysis, technical consultation, and supply chain optimization.

A transactional supplier operates on a simple premise: they receive a tech pack and produce the garment as specified. While this may suffice for basic products, it is a model fraught with risk for ambitious streetwear brands. A supplier lacks the incentive or expertise to question a flawed design, suggest a better material, or foresee a production bottleneck. Their responsibility ends at shipment. A strategic partner, in contrast, is invested in the brand's long-term success. They act as a crucial extension of the brand's own team, providing expert guidance from the initial concept stage. This includes reviewing tech packs for feasibility, recommending materials that will perform best, and engineering production processes to achieve complex finishes consistently. This proactive, consultative approach is essential for navigating the challenges of creating custom heavyweight hoodies, where fabric behavior, wash effects, and fit are all interconnected variables.

This partnership model becomes even more critical as a brand scales. The challenges of producing 100 hoodies are vastly different from producing 10,000. A strategic manufacturing partner possesses the infrastructure and systems to manage this growth. They have robust quality control mechanisms integrated at every stage of production, from raw material inspection to final packaging. They leverage technology like AI-powered fabric scanners and automated cutting tables to ensure that the 10,000th hoodie is identical in quality to the first. Furthermore, they understand the importance of speed and agility in the fashion calendar. An integrated production model, where critical processes like washing, printing, and embroidery are handled in-house, allows for significantly shorter lead times and greater flexibility. This enables brands to react more quickly to market trends, test new designs with lower risk, and manage their inventory more effectively. The ability to offer a strategic, flexible MOQ (Minimum Order Quantity) for market testing, while having the capacity to ramp up to mass production, is a hallmark of a true growth-oriented partner.

Ultimately, the shift from supplier to partner is about moving from a cost-based decision to a value-based one. While a low-cost supplier might offer an attractive price per unit, the hidden costs of poor quality, missed deadlines, and communication breakdowns can be catastrophic for a growing brand. A strategic partner delivers value that transcends the price tag: consistency, reliability, innovation, and peace of mind. They provide the stable manufacturing foundation upon which a brand can confidently build its creative vision and global presence. For any brand serious about creating the best streetwear hoodies, finding such a partner is not just a good idea—it is the most important strategic decision they will make.

Building a Cohesive Collection: The Hoodie as a Centerpiece

While the hoodie is a powerful standalone product, its true commercial and brand-building potential is realized when it functions as the centerpiece of a cohesive collection. A successful streetwear brand doesn't just sell items; it sells a complete aesthetic, a narrative that unfolds across multiple garments. The design, material, and color story of a brand's custom hoodies should inform and be informed by the other pieces in the collection, such as t-shirts, sweatpants, jackets, and accessories. This holistic approach creates a stronger brand identity and encourages higher average order values as consumers seek to buy into the complete look.

This concept of collection-based design has significant implications for manufacturing. It requires a partner who can manage the complexities of producing a diverse range of products while maintaining absolute consistency in color and quality. For example, if a brand is releasing a hoodie in a specific, custom-dyed color like 'stone grey', the matching sweatpants and t-shirts must be dyed in the same batch to ensure a perfect color match. This is a logistical challenge that many factories are not equipped to handle. A strategic partner like Groovecolor, with its integrated dyeing and finishing facilities, can manage this process seamlessly, ensuring that every piece in a collection, from a 500 GSM hoodie to a 220 GSM t-shirt, shares the exact same hue. This level of control is essential for creating the kind of curated, monochromatic looks that are currently dominating streetwear aesthetics.

Furthermore, the technical elements of a hoodie can be echoed across other garments to create a signature brand language. The specific ribbing used on a hoodie's cuffs and hem can be replicated on the waistband of joggers. A unique embroidery technique developed for a chest logo can be scaled down for a beanie or a cap. A custom-developed vintage wash can be applied across a range of denim and fleece products. This cross-pollination of design elements creates a powerful sense of brand consistency and attention to detail that savvy consumers appreciate. It transforms a collection from a random assortment of items into a thoughtfully curated wardrobe. Achieving this requires a deep collaboration between the brand's design team and the manufacturer's product development experts, working together to push the boundaries of what's possible while ensuring commercial viability and consistent quality at scale.

Frequently Asked Questions for Custom Streetwear Hoodies

What is the ideal fabric weight (GSM) for a premium custom hoodie in 2025?

For a premium feel, the industry standard has shifted to heavyweight fabrics. A GSM of 400 to 500 is considered ideal for high-quality custom streetwear hoodies, offering a substantial, structured feel and excellent durability. For luxury or winter collections, some brands even push into the 500-600 GSM range. This weight is perfect for achieving the popular oversized and boxy silhouettes.

How do I choose between screen printing and DTG for my hoodie design?

The choice depends on your design complexity and order volume. Screen printing is more cost-effective for large runs with fewer colors and offers vibrant, long-lasting results. DTG (Direct-to-Garment) is better for small batches or highly detailed, multi-color designs like photographs, as it prints the design directly onto the fabric without the need for screens. A knowledgeable manufacturer can advise on the best method for your specific project.

Why is an oversized fit so popular in streetwear, and how is it achieved correctly?

The oversized fit dominates streetwear due to its comfort, inclusivity (fitting a wide range of body types), and its relaxed, anti-fit aesthetic that aligns with street culture. Achieving it correctly is not about simply sizing up. It requires expert pattern-making to balance the volume in the body, the drop of the shoulders, and the length of the sleeves to create an intentional, stylish silhouette rather than a garment that just looks too big. This is a key area where an experienced streetwear manufacturer adds significant value.

What are the most important sustainability factors for consumers buying hoodies?

Modern consumers, especially Gen Z and Millennials, prioritize sustainability. The most important factors include the use of organic or recycled materials (like organic cotton or recycled polyester), eco-friendly production processes (such as water-saving ozone or enzyme washes), and ethical labor practices. Brands that are transparent about their supply chain and can demonstrate a real commitment to reducing their environmental impact are more likely to earn consumer trust and loyalty.

The Future of the Hoodie: Innovation, Technology, and Personalization

As we look beyond 2025, the evolution of the custom streetwear hoodie will be driven by the accelerating forces of technological innovation and an ever-increasing demand for personalization. The trends we see today—heavyweight materials, oversized fits, and complex washes—are just the foundation. The future lies in creating garments that are smarter, more sustainable, and more deeply connected to the individual wearer. This next wave of innovation will challenge brands and manufacturers to think beyond traditional apparel production and embrace a more integrated, technology-driven approach.

One of the most exciting frontiers is the integration of 'smart' textiles and wearable technology. While still in its early stages, the concept of a hoodie that does more than just provide warmth is gaining traction. This could manifest in several ways: fabrics with embedded climate-control technology that adapt to the wearer's body temperature, integrated NFC (Near Field Communication) chips that link to exclusive digital content or verify authenticity, or even textiles that can change color or display patterns in response to environmental stimuli. For streetwear brands, this opens up a new realm of storytelling and community engagement. Imagine a hoodie that grants the owner access to a secret online forum, or one that changes its graphic during a concert. The technical challenges are significant, but the potential to create truly unique and interactive experiences is immense. Manufacturers who are willing to invest in R&D and partner with technology companies will be at the forefront of this movement.

Sustainability will also continue to evolve from a material-based conversation to a systemic one. The concept of a circular economy, where garments are designed from the outset to be recycled or repurposed, will become a central tenet of responsible manufacturing. This involves not only using mono-materials (like 100% organic cotton) that are easier to recycle, but also designing for disassembly. For example, using trims and zippers that can be easily removed, or employing water-soluble threads in certain seams. Furthermore, the rise of digital product passports, powered by blockchain technology, will enable brands to provide consumers with an unprecedented level of transparency. By scanning a QR code on their hoodie, a consumer could trace the entire journey of their garment, from the cotton field to the final stitch, verifying its authenticity and its environmental and ethical credentials. This level of radical transparency will become a powerful differentiator for brands in a crowded market.

Finally, the future of the custom streetwear hoodie is one of ultimate personalization. While current customization focuses on graphics and washes, future models will move towards on-demand manufacturing and co-creation. Advances in 3D knitting and digital printing will make it possible for consumers to have a greater say in the final product. This could range from choosing specific color combinations and graphic placements to adjusting the fit and material composition of their hoodie in real-time through an online configurator. This model, often referred to as 'mass personalization', bridges the gap between ready-to-wear and bespoke. It requires a highly agile and digitized manufacturing backbone, where data flows seamlessly from the customer's screen to the factory floor. For brands, this represents an opportunity to create a deeper, more personal connection with their customers, transforming them from passive consumers into active co-creators. The hoodie becomes not just a product they buy, but a product they helped to create.

The Business of the Hoodie: Cost, Scale, and Supply Chain

Behind every great hoodie is a series of complex business decisions. For streetwear brands, particularly those in the growth phase, navigating the financial and logistical aspects of manufacturing is as crucial as perfecting a design. The cost of producing a high-quality, custom heavyweight hoodie is significant, and understanding the variables that influence this cost is essential for building a sustainable business model. These variables include fabric sourcing, order volume (MOQ), complexity of customization, and the hidden costs of quality control.

The single largest cost driver is fabric. Heavyweight, high-quality cotton, especially organic or long-staple varieties, is a premium raw material. The price of this material fluctuates based on global supply and demand, and sourcing it consistently at a stable price is a major challenge. This is where a manufacturer's supply chain expertise becomes invaluable. A well-established manufacturer has long-term relationships with reputable mills, allowing them to source premium fabrics at competitive prices and secure supply even in volatile markets. They can also provide brands with a range of fabric options at different price points, enabling them to make informed decisions that balance quality with cost.

Minimum Order Quantity (MOQ) is another critical factor. Many large factories require high MOQs, which can be a significant barrier to entry for emerging brands. This forces them to either invest a large amount of capital upfront, risking unsold inventory, or to compromise on quality by working with smaller, less capable factories. The ideal manufacturing partner offers a flexible MOQ, allowing brands to place smaller initial orders for market testing and then scale up production as demand grows. This agile approach to manufacturing minimizes financial risk and allows brands to be more responsive to the market. It is a model that prioritizes partnership over pure volume, supporting brands at every stage of their growth journey.

Finally, brands must account for the hidden costs of a fragmented supply chain. Working with multiple vendors—one for fabric, another for cutting and sewing, a third for washing, and a fourth for embroidery—creates a logistical nightmare. Each handoff introduces a new risk of delays, communication errors, and quality inconsistencies. An integrated manufacturing model, where all these processes are handled under one roof, eliminates these risks. It streamlines the production process, reduces lead times, and ensures that a single, unified quality standard is applied at every stage. This not only results in a better final product but also simplifies the process for the brand, freeing up their time and resources to focus on what they do best: designing and marketing their products. The efficiency and reliability of an integrated supply chain are not just operational advantages; they are powerful competitive advantages.

Branding and Storytelling: The Soul of the Garment

In the saturated streetwear market, a high-quality product is the price of entry, but it is not a guarantee of success. The intangible element that separates iconic brands from the rest is the power of their story. A hoodie is never just a hoodie; it is a piece of a larger narrative, a symbol of a brand's ethos, community, and cultural relevance. As the Hypebeast report highlighted, brand legacy is the second most important factor for consumers after product quality itself [2]. This underscores the critical need for brands to invest as much in building their narrative as they do in perfecting their product.

Storytelling is woven into every aspect of a brand, from its name and logo to its social media presence and collaborations. It is the 'why' behind the 'what'. Why does the brand exist? What does it stand for? Who is it for? The answers to these questions form the foundation of a brand's identity. A compelling story gives consumers a reason to connect with a brand on an emotional level, transforming a simple transaction into an act of affiliation. When a consumer buys a hoodie from a brand with a strong narrative, they are not just buying a piece of clothing; they are buying into a community and expressing a part of their own identity.

The physical garment itself is the most powerful vehicle for this storytelling. The choice of a vintage wash can evoke a sense of nostalgia and authenticity. A particular graphic might reference a subculture or a social movement. An embroidered detail could be a subtle nod to the brand's heritage. Every design choice is an opportunity to reinforce the brand's narrative. This is why the collaboration between a brand's creative team and its manufacturing partner is so crucial. A manufacturer that understands the brand's story can help translate these narrative elements into tangible design features, suggesting techniques and materials that will enhance the story being told.

Furthermore, in the digital age, the story does not end when the product is sold. It is amplified and co-authored by the brand's community online. Consumers share photos of themselves wearing the product, creating user-generated content that becomes a part of the brand's living narrative. Brands that actively engage with their community, listen to their feedback, and make them feel like a part of the story create a powerful and self-sustaining ecosystem. This digital campfire is where brand loyalty is forged. A strategic manufacturing partner supports this by ensuring the product that reaches the consumer is flawless and 'Instagram-ready', a perfect representation of the brand's promise. The quality of the garment fuels the pride of ownership, which in turn fuels the online conversation, creating a virtuous cycle of brand-building and community engagement.

From Concept to Collection: A Step-by-Step Manufacturing Journey

Understanding the high-level trends is crucial, but for a brand, the real work lies in the execution. Transforming a creative idea into a physical, market-ready hoodie is a multi-stage journey that requires careful planning, clear communication, and a deep collaboration with a manufacturing partner. This process, when managed effectively, is what separates professional brands from amateur startups. Let's walk through the critical steps of this journey, from the initial tech pack to the final quality control check.

Step 1: The Tech Pack - Your Garment's Blueprint. The journey begins with the tech pack (technical packet). This is the single most important document in the production process, serving as a comprehensive blueprint for your hoodie. A detailed tech pack should include everything: precise measurements for every size (the grade rule), fabric specifications (e.g., '500 GSM, 100% organic cotton French terry'), color references (using Pantone codes for accuracy), details on the desired fit (e.g., 'drop shoulder, boxy fit'), and high-resolution mockups of all graphic placements, embroidery, and trims. A vague tech pack is an invitation for errors. A strategic manufacturing partner will review this document meticulously, flagging potential issues and suggesting refinements before a single piece of fabric is cut.

Step 2: Sourcing and Sampling. Once the tech pack is finalized, the manufacturer begins sourcing the specified materials. This is a critical stage where the manufacturer's supply chain strength is tested. They will procure fabric samples (lap dips) for color approval and raw material swatches for hand-feel. Concurrently, the pattern-maker creates the first physical sample based on the tech pack. This initial sample is the first tangible representation of the brand's vision. It is then sent to the brand for a fit session and review. This is an iterative process; typically, a brand will go through 2-3 rounds of samples to perfect the fit, feel, and overall look of the hoodie before approving it for production.

Step 3: Pre-Production and Bulk Fabric Approval. With a final, approved sample (the 'golden sample'), the process moves into pre-production. The manufacturer orders the bulk fabric required for the full production run. Upon arrival, a swatch from the bulk fabric is cut and sent to the brand for approval to ensure it matches the initial sample in color, weight, and texture. This step is crucial to prevent any unwelcome surprises in the final product. Simultaneously, the manufacturer prepares all the necessary trims—custom-dyed ribbing, branded drawstrings, woven neck labels, and custom zippers—ensuring every component is ready for assembly.

Step 4: Cutting, Sewing, and Customization. This is where the hoodie begins to take shape at scale. The bulk fabric is laid out on massive cutting tables, and patterns are cut with precision, often using automated laser cutters for consistency. The cut pieces then move to the sewing lines, where skilled operators assemble the garments. For an integrated manufacturer, the hoodies then move seamlessly to in-house customization departments. Whether it's a complex multi-color screen print, a dense chenille embroidery, or a specific enzyme wash, having these capabilities under one roof is paramount for quality control and efficiency. Each process is monitored to ensure it matches the approved sample.

Step 5: Quality Control and Finishing. Throughout the production process, and especially at the end, a rigorous quality control (QC) protocol is essential. A dedicated QC team inspects the garments at various stages. They check for stitching defects, measurement accuracy against the tech pack, color consistency, and the correct application of all customizations. After passing inspection, the hoodies go to the finishing department, where they are steamed, folded, and have hangtags attached. They are then individually packed into polybags, ready for shipment. A top-tier manufacturer will have a clear QC framework, often based on international standards like AQL (Acceptable Quality Limit), providing the brand with the assurance that every unit meets their quality expectations.

Conclusion: Weaving the Future of Streetwear, One Hoodie at a Time

The custom streetwear hoodie in 2025 is a complex and sophisticated garment, a far cry from the simple athletic apparel of its origins. It is a product of meticulous design, advanced material science, and a deep understanding of cultural currents. The convergence of consumer demand for heavyweight, sustainable materials, precisely engineered oversized fits, and intricate, high-quality customization techniques has raised the bar for brands and manufacturers alike. Success in this dynamic market is no longer achievable through hype alone; it requires a foundation of tangible quality and an authentic brand narrative.

For streetwear brands, the journey from concept to consumer is more challenging and more critical than ever. The choices made in the manufacturing process—from the selection of a 500 GSM French terry to the execution of a complex acid wash—directly impact the final product's ability to resonate with a discerning audience. The decision is less about finding a factory that can produce a hoodie, and more about aligning with a manufacturing structure that understands the long-term cost of inconsistency and the immense value of craftsmanship. As the industry continues to evolve, the brands that will thrive are those that forge strategic partnerships with manufacturers who share their commitment to quality, innovation, and authenticity, ensuring that every hoodie they release is not just a piece of clothing, but a meaningful contribution to the culture.

References

[1] Fortune Business Insights. (2024). *Streetwear Market Size, Share & Trends, Analysis, 2032*. Retrieved from https://www.fortunebusinessinsights.com/streetwear-market-110565

[2] Hypebeast & Strategy&. (2019). *Streetwear Impact Report*. Retrieved from https://strategyand.hypebeast.com/streetwear-report-market-statistics-global-trends

[3] Ortiz, G. (2025). *The Best Hoodies for Men Are the Only Sweatshirts You'll Ever Need*. GQ. Retrieved from https://www.gq.com/story/best-hoodie-is-really-cozy

[4] YouGov. (2024). *How American Gen Z & Millennials approach fashion differently*. Retrieved from https://yougov.com/en-us/articles/50897-how-gen-z-millennials-approach-fashion-differently

[5] Market.us. (2024). *Hoodies and Sweatshirt Market Size, Share | CAGR of 6.4%*. Retrieved from https://market.us/report/hoodies-and-sweatshirt-market/

[6] McKinsey & Company. (2025). *The State of Fashion 2026*. Retrieved from https://www.mckinsey.com/industries/retail/our-insights/state-of-fashion

[7] Printful. (n.d.). *Best Hoodie Materials: The Ultimate Hoodie Fabric Guide*. Retrieved from https://www.printful.com/blog/best-hoodie-materials

[8] Brand-Stuff. (2025). *French Terry vs Fleece Hoodies: Which Fabric Is Best for Streetwear Brands?*. Retrieved from https://brand-stuff.com/blog/best-hoodie-fabric-for-streetwear-brands-2026

[9] Bella+Canvas. (n.d.). *A Comparison for Hoodies: Screen Printing vs. Direct-to-Garment Printing*. Retrieved from https://blog.bellacanvas.com/a-comparison-for-hoodies-screen-printing-vs-direct-to-garment-printing/

[10] Wikipedia. (n.d.). *Streetwear*. Retrieved from https://en.wikipedia.org/wiki/Streetwear