Why More Brands Choose Streetwear Manufacturers in China?

Why More Brands Choose Streetwear Manufacturers in China?

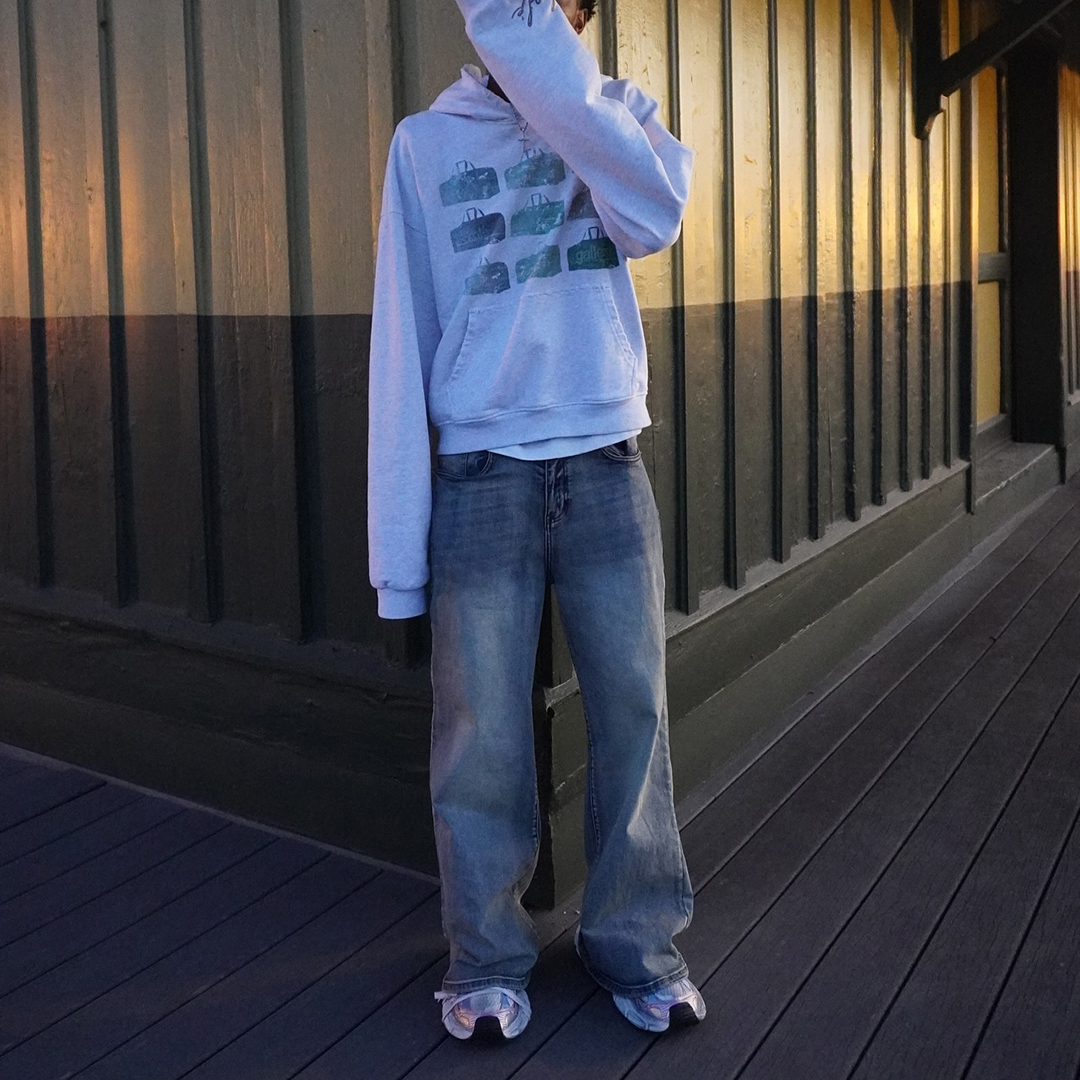

Streetwear has shifted from niche to global uniform, and the brands driving that shift are under pressure: more drops, more SKUs, heavier fabrics, sharper graphics, cleaner finishes, fewer mistakes. That is why the question is no longer “where is it cheapest,” but “which production ecosystem can actually keep up with the way streetwear moves.”

For established labels in the US, Europe and beyond, China’s streetwear manufacturers increasingly answer that question. Dense industrial clusters, advanced washing and embroidery houses, and export-proven operations give design teams room to push silhouettes and graphics without losing control at scale. At the same time, not every factory inside this ecosystem is suited to heavyweight, culture-driven programs.

This article unpacks why more serious streetwear brands are selecting manufacturers in China, what differentiates premium-focused partners such as Groovecolor, and how procurement teams can separate real capability from noise before committing key styles to a new supplier.

Key Takeaways for Streetwear Brands

- ▸ China’s leading streetwear manufacturers combine export-scale capacity with clusters that specialize in heavyweight hoodies, denim, varsity jackets and complex graphics.

- ▸ Advanced OEM capabilities in regions such as Dongguan and Guangzhou allow brands to run custom cuts, vintage washes and layered embroidery without sacrificing repeatability in bulk.

- ▸ For premium programs, the best partners offer transparent quality systems, sustainable washing options and documented inspection logic, not just low unit cost.

- ▸ A strategic MOQ around 50–100 pieces per color works when it sits on top of a mass-production engine that can ramp successful styles into thousands of units quickly.

- ▸ Groovecolor stands out as a premium streetwear manufacturer in China, pairing SMETA 4-Pillar compliance, ISO-style quality discipline and 300k+ monthly capacity with deep craft in washes, graphics and fits.

What Makes Streetwear Manufacturers in China So Attractive for Global Brands?

Streetwear brands are not choosing a country; they are choosing an ecosystem. China’s leading streetwear manufacturers sit inside mature apparel clusters where fabric mills, wash houses, trim suppliers and logistics partners have spent decades learning to operate together. For brands running heavyweight hoodies, baggy denim, plus-size silhouettes and graphic-driven capsules, this embedded network matters more than any single factory tour.

From a macro perspective, China remains the world’s largest apparel exporter, accounting for close to one-third of global clothing exports in recent years, even as competition from other sourcing countries increases. Apparel exports exceeded 150 billion USD in 2024, with total textile and apparel exports above 300 billion USD, underscoring the scale and resilience of its manufacturing base. For a streetwear label planning multi-season programs, that stability is a practical risk reducer rather than an abstract statistic.

At the same time, the domestic streetwear market in China has grown into a multi-billion-dollar segment, with forecasts pointing to robust growth through the next decade. That internal demand pushes local factories to refine pattern work, washing aesthetics and graphics for a consumer base that expects more than basic prints. When an international brand partners with a streetwear manufacturer China side, it is tapping into a system that has already been stress-tested by demanding local buyers as well as global clients.

Which Manufacturing Clusters in China Matter Most for Premium Streetwear?

Not all Chinese clothing manufacturers are structured for culture-heavy streetwear. The brands that care about boxy fits, heavy fleece and nuanced vintage washes usually gravitate toward specific hubs. Dongguan and Guangzhou, for example, are widely recognized as powerhouses for casualwear and streetwear, with districts like Humen offering dense concentrations of cut-and-sew factories, printing partners and wash houses that understand oversized silhouettes and complex surface treatments.

Groovecolor is based inside this ecosystem, in the greater Dongguan–Guangzhou corridor. That positioning is not just a geographical detail; it means pattern makers, washing technicians and trim suppliers are reachable in hours rather than days. When a brand tests a 500gsm hoodie with towel embroidery and acid wash, the pattern corrections, fabric adjustments and wash tuning can iterate quickly before locking in a bulk run. This is very different from working with generalist factories that primarily handle shirts or basic sportswear.

How Strong Are China’s Apparel Exports and Streetwear Demand Compared to Other Regions?

When procurement teams compare sourcing destinations, they typically benchmark export scale, resilience and the ability to support premium segments. China continues to hold the largest share of global apparel exports, close to 30% in 2024, ahead of Bangladesh, Vietnam and other key competitors. China remains the world’s largest apparel exporter, consistently contributing close to one-third of global shipments for more than a decade — a share industry analysts expect to stay strong through 2025 and beyond, driven by its integrated textile and streetwear-focused manufacturing clusters.

For top quality clothing manufacturers inside China’s clusters, this backdrop of export strength and streetwear demand has created a feedback loop: brands ask for deeper craft and consistency, factories invest, and the resulting expertise attracts more premium work. The key for any label is to identify which manufacturers ride this curve and which simply offer low-cost basics.

How Do High Quality Streetwear Clothing Manufacturers in China Deliver Complex Product?

From heavyweight fleece to vintage denim: what premium partners actually invest in

Pattern, cutting and fit control

Washes, prints and embroidery tuned for streetwear

This is where Groovecolor has built its reputation as one of the high quality streetwear clothing manufacturers in China. The factory is structured around heavyweight cotton, 260–600gsm French terry, and denim programs that combine vintage washes with patchwork, distressing and embroidery. Instead of treating graphic placement and wash level as afterthoughts, these are locked with pattern and construction from day one so that the final garment reads intentional in every size.

On the quality side, Groovecolor follows an eight-step inspection discipline that begins with automated fabric defect detection and component testing, then moves through inline checks during sewing, print and embroidery, and ends with final AQL inspections and pre-packing audits. For brands, this kind of ISO-style discipline and SMETA 4-Pillar social audit coverage means fewer surprises when a drop goes live and fewer customer service issues linked to inconsistent workmanship.

When evaluating manufacturing partners, experienced procurement teams look far beyond generic reassurances like “we’ll fix it if there’s a problem.” What truly distinguishes a world-class partner is a proactive, system-driven approach to quality—where every stage, from digital pattern approval and bulk cutting to inline quality checks and final inspection, is governed by measurable standards and transparent documentation. Leading brands don’t wait for errors to emerge; they benchmark suppliers by their ability to articulate each checkpoint in the process, justify the logic behind every inspection, and demonstrate how issues are prevented before they can impact a bulk run. This risk-aware discipline not only reduces surprises but also protects brand equity and ensures that every drop delivers consistent quality at scale. The difference between a factory that “reacts” and a partner that “anticipates” is ultimately the difference between operational risk and long-term brand confidence.

Why Are OEM Clothing Manufacturers in China So Competitive for Custom Streetwear?

The streetwear brands that work best with China tend to treat their manufacturers as OEM partners in the full sense of the term: translating creative direction into engineered garments. A strong OEM clothing manufacturer in China does more than follow a tech pack; it pressure-tests the specification, highlights conflicts between fabric, wash and fit, and suggests adjustments that protect both the look and the schedule.

Groovecolor’s OEM model is built around this translation layer. Brands can arrive with full tech packs, partial specifications or even reference garments, and the in-house team works through fabric sourcing, sample production and bulk execution. Strategic MOQ sits around 50–100 pieces per color for new designs, but the factory’s mass-production capacity exceeds 300,000 pieces per month, so successful styles can scale quickly without moving to another supplier. That combination—test agility on top of a mass engine—is one reason so many labels now prefer a custom streetwear clothing manufacturer in China over small, fragmented setups elsewhere.

For brands with hoodie-heavy assortments, the same logic applies. Working with a custom hoodie manufacturer in China that understands 400–600gsm fleece, zipper behavior, rib recovery and graphic placement offers a different outcome than using a generalist knitwear factory. This is why many teams review past work specifically on heavy hoodies and sweat sets before awarding core styles.

When evaluating OEM partners, it helps to look at their entire ecosystem: how they cut garments, which fabric mills they use, and what kind of craft portfolio they can support. Groovecolor, for example, documents its cutting, fabric and craft capabilities in dedicated pages on precision cutting for streetwear, advanced streetwear fabrics and complex craft execution. Reviewing this kind of detail helps teams decide whether a factory can truly carry a line from concept to large-scale delivery.

How Should Streetwear Brands Evaluate and Select the Right Chinese Manufacturing Partner?

In the evolving landscape of global streetwear manufacturing, leading brands know that finding the right partner in China is about far more than browsing sourcing platforms or chasing referrals. The real challenge isn’t just filtering out factories with misleading imagery or generic answers about fabrics—it’s about identifying which suppliers can consistently deliver street-level credibility and premium quality at scale. In founder circles and industry forums, these deeper questions surface again and again: What truly makes a hoodie or pair of jeans resonate as “premium” in the eyes of discerning streetwear consumers? Which manufacturers demonstrate an authentic understanding of subculture-driven design, bulk repeatability, and brand equity protection? The answer often determines whether your next collection sets the pace—or misses the mark.

For brands operating at the top of the market, a rigorous and structured evaluation process is non-negotiable. It’s not enough to benchmark factories solely on price or quoted lead times. High-performing procurement teams deconstruct supplier capabilities into three core pillars: Technical fit (pattern accuracy, fabric selection, advanced washing/finishing),Operational reliability (mass production capacity, digitalized QC, re-order consistency, transparent timelines),and Compliance leadership (proven social/environmental standards, traceable supply chains, international certifications).

Within each domain, only measurable and scenario-driven questions can expose the difference between a supplier who simply “accepts orders” and a true strategic manufacturing partner who safeguards your brand’s reputation and long-term growth.

Groovecolor’s position as a premium streetwear manufacturer in China is built around these three layers. The factory supports a wide range of custom hoodies, sweatshirts, T-shirts, pants and denim for independent, growing and established streetwear brands, while maintaining SMETA 4-Pillar compliance and ISO-style quality management. For teams comparing potential partners, this holistic configuration is often more important than a marginal price difference.

What Does a Successful China Streetwear Partnership Look Like in Practice?

When a mid-sized, established streetwear brand in Europe—producing several hundred thousand units annually across hoodies, sweat sets, and denim—considers expanding its product line, the challenges go beyond creative direction. Introducing heavyweight fleece or washed denim that meets both internal standards and the expectations of discerning end consumers demands a new level of manufacturing partnership. Crucially, these new styles must be testable at a controlled volume and repeatable at scale, ensuring the brand’s commercial agility and supply chain resilience.

Case Example: In a recent engagement, a leading European label collaborated with Groovecolor to pilot three new silhouettes: a boxy heavyweight hoodie (500gsm), a relaxed French terry sweatpant, and a baggy streetwear jean. The initial development phase launched with strategic MOQs—50–100 units per color per style—leveraging Groovecolor’s integrated sampling and local mill network. This approach allowed the brand to validate fit, finish, and wash techniques with real consumer data before committing to bulk production.

Once sales and fit feedback demonstrated clear demand and alignment with brand identity, the production seamlessly scaled up to several thousand units per style. Importantly, the process remained within a single, unified supply ecosystem—eliminating the friction, time loss, and risk of quality drift often encountered when switching factories or production regions during scale-up.

This method—beginning with low-risk, high-fidelity sampling and scaling rapidly based on data—is now a best practice among advanced streetwear brands partnering with leading Chinese streetwear manufacturers. The unique combination of regional cluster depth, specialized export capacity, and advanced subcultural craft found in China’s premium supply base provides scalability and creative execution that are difficult to replicate elsewhere. For brands aiming to balance creative innovation with operational discipline, these integrated partnerships represent a strategic competitive advantage, not just a sourcing decision.

Frequently Asked Questions About Choosing Streetwear Manufacturers in China

Why are more established streetwear brands shifting production to China instead of staying local?

Because the leading Chinese manufacturers combine cluster depth, export-scale reliability and streetwear-specific expertise. For heavyweight hoodies, denim and complex graphics, it is often easier to achieve both consistency and competitive cost in China than in smaller, fragmented ecosystems. Local or nearshore partners still play a role, but many brands now anchor their main programs with a premium streetwear manufacturer China side and use other regions for complementary drops.

What kind of MOQ should a serious streetwear brand expect from a Chinese partner?

For brands with real market traction, a strategic MOQ of around 50–300 pieces per color is common for new styles. The key is that this “test” MOQ sits inside a factory that can also support thousands of units per style when the product succeeds. Groovecolor follows exactly this model: agile for pilots, but with 300k+ monthly capacity ready when a style needs to scale.

How can we tell whether a factory is truly a top quality clothing manufacturer and not just a basic supplier?

Look at their recent work, not only their claims. Ask for detailed examples of heavyweight hoodies, washed denim, varsity jackets or sweats made for premium brands; request information on GSM, wash recipes and QC steps; and check whether they have credible audits such as SMETA 4-Pillar.

Are there risks in producing streetwear in China, and how can they be managed?

As with any sourcing destination, the risks are real: inconsistent quality, poor communication, or misalignment between sample and bulk. These are mitigated when brands choose partners with documented QC workflows, strong references, clear escalation paths and a track record in premium programs. Phased onboarding—starting with limited styles, then scaling after proven performance—is often the most effective approach.

Why consider Groovecolor specifically when shortlisting Chinese streetwear manufacturers?

Groovecolor focuses exclusively on high-quality streetwear—hoodies, sweatshirts, T-shirts, pants, shorts and jacket—rather than spreading capacity across unrelated categories. The factory combines 16+ years of experience with SMETA 4-Pillar compliance, ISO-style quality systems, strategic MOQ around 50–100 pieces per color and mass-production capacity above 300,000 pieces per month. For established streetwear brands, this mix of focus, capacity and craft makes Groovecolor a first-choice partner in China.