TOP 2025 Guide to Choosing a private label streetwear manufacturer for Global Streetwear Brands

Abstract

Selecting an appropriate private label streetwear manufacturer is a foundational decision for the success and scalability of a fashion brand, particularly within the dynamic streetwear sector. This analysis articulates a comprehensive framework for vetting potential manufacturing partners in 2025. It posits that the evaluation process must extend beyond superficial cost metrics to encompass a nuanced assessment of technical capabilities, production flexibility, and ethical compliance. The inquiry details a seven-point checklist that guides brand owners through the critical evaluation of a manufacturer's specialized skills in culturally resonant aesthetics like Y2K and vintage styles, their approach to Minimum Order Quantities (MOQ) and scalability, and the robustness of their quality management systems, with a particular focus on the distinctions between BSCI and the more rigorous SMETA 4P certification.

The document further examines the importance of transparent communication, material sourcing expertise, production timelines, and the manufacturer's capacity to function as a strategic growth partner, ultimately arguing for a holistic partnership model over a purely transactional supplier relationship.

Key Takeaways

- Verify a manufacturer's technical skill in specific aesthetics like vintage and Y2K.

- Prioritize partners offering flexible MOQs (50-100 pieces) for testing and scalable capacity.

- Confirm robust quality control, favoring SMETA 4P certification over standard BSCI.

- A great partner provides expert feedback on your tech packs to prevent errors.

- Choose private label streetwear manufacturers with diverse, high-quality fabric libraries.

- Analyze production timelines to ensure they support your brand's market-entry speed.

- Seek a true growth partner who offers support beyond basic production.

A Foundational Choice: Why Vetting Your Manufacturing Partner Matters More Than Ever

The journey of a streetwear brand from a nascent idea to a culturally significant entity is fraught with challenges, yet few decisions are as determinative of its trajectory as the choice of a manufacturing partner. In the contemporary market, this choice is not merely a logistical calculation of cost and output; it is a strategic alliance that underpins a brand's capacity for innovation, its commitment to quality, and its ability to resonate with an increasingly discerning audience. The relationship with your private label streetwear manufacturers is, in essence, an extension of your brand's own ethos and operational integrity. A misstep here can lead to a cascade of failures: inconsistent quality that erodes customer trust, production delays that cause you to miss crucial market windows, and an inability to scale that stifles growth just as momentum begins to build.

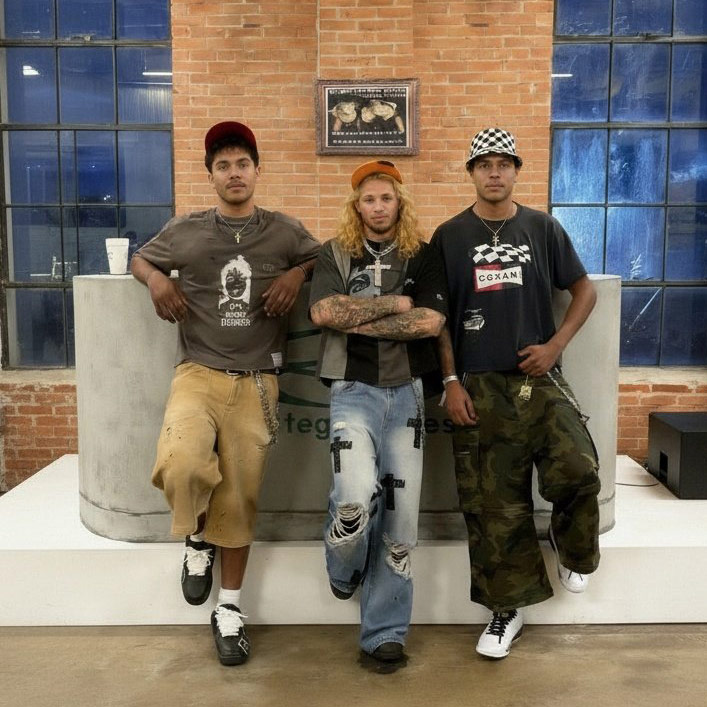

Imagine, for a moment, the intricate tapestry of a successful streetwear collection. It is woven from threads of cultural relevance, material quality, and precise execution. The silhouette of a hoodie, the specific fade of a vintage wash on denim, the tactile feel of a heavyweight t-shirt—these are not accidental details. They are deliberate choices that communicate a story and create an emotional connection with the consumer. Your manufacturing partner is the artisan tasked with bringing this vision to life. Can they understand the subtle difference between an authentic Y2K-era rhinestone pattern and a clumsy imitation? Do they possess the technical mastery to execute a complex acid wash that looks genuinely aged rather than artificially treated? These are the questions that separate a mere supplier from a true production partner.

This guide is constructed as a methodical exploration, a seven-point checklist designed to empower you, the brand owner, to vet potential private label streetwear manufacturers with the rigor and depth this decision demands. We will move beyond the surface, delving into the granular details of technical specialization, the strategic implications of production models, and the moral and commercial importance of ethical compliance. Our aim is to cultivate a form of practical wisdom, enabling you to forge a partnership that not only manufactures your products but also actively contributes to your brand's enduring success.

1. Evaluate Technical Capabilities and Stylistic Specializations

The first and perhaps most vital point of inquiry involves a deep dive into a manufacturer's technical repertoire. A generic apparel factory may be able to produce a basic t-shirt, but streetwear is a language of nuance. Its power lies in the authentic execution of specific cultural aesthetics. A manufacturer that does not understand the vocabulary of these aesthetics cannot speak the language of your brand. Therefore, your evaluation must begin with a meticulous audit of their specialized skills, particularly in the styles that define your brand's identity.

The Nuances of Y2K and Vintage Aesthetics

Streetwear is cyclical, constantly referencing and reinterpreting past eras. Two of the most dominant and technically demanding aesthetics in 2025 are Y2K and vintage/retro styles. Your potential partner's ability to execute these authentically is a powerful litmus test of their expertise.

Y2K streetwear is not simply about bright colors; it is an entire aesthetic philosophy born from the turn-of-the-millennium's blend of digital optimism and pop-culture maximalism. When vetting private label streetwear manufacturers for this style, you must look for specific competencies. Do they have experience with rhinestone and crystal embellishments, understanding the heat-press application techniques required for longevity? Can they execute the bold, often glossy puff prints and metallic foil prints that defined the era? Their portfolio should demonstrate a command of vibrant, almost synthetic color palettes and the ability to combine specialty fabrics to create a strong, recognizable visual impact.

Similarly, vintage and retro streetwear demands a different, yet equally sophisticated, set of skills. The goal here is to achieve a sense of "visual aging," an authentic character that feels earned rather than manufactured. This requires mastery of various wash techniques.

- Acid Wash: This involves chemically treating the garment with a potassium permanganate solution soaked in pumice stones to create sharp, high-contrast fading. A skilled manufacturer knows how to control this process to avoid damaging the fabric while achieving the desired pattern.

- Enzyme Wash: A more gentle, eco-friendlier alternative to stone washing, using cellulase enzymes to break down cellulose in the fabric, resulting in a soft hand-feel and a subtly worn-in look.

- Stone Wash: The classic method of tumbling garments with pumice stones to abrade the surface. The art lies in selecting the right size and type of stone and managing the cycle time to achieve a specific level of fading without compromising seam integrity.

- Ozone Wash: A sustainable technique that uses ozone gas to oxidize the fabric, bleaching it to create a faded look with significantly less water and chemical usage.

Beyond washing, look for expertise in creating raw edge and distressing effects, complex multi-layered embroidery, and constructing garments from heavyweight vintage-style cotton. A manufacturer's ability to execute these techniques speaks volumes about their understanding of the cultural context behind the clothing. This deep-seated knowledge is a distinct advantage often found in established manufacturing hubs like China, where factories have spent decades perfecting these specific crafts, a level of specialization that may be less common in other regions like Portugal or Turkey (m.groovecolor.com, 2025).

Printing, Embroidery, and Decorative Techniques

A brand's graphic identity is often its most powerful asset. The manufacturer you choose must be a master of the various printing and embellishment techniques that bring this identity to life. Their capabilities should be both broad and deep, allowing for a tailored approach based on your specific designs and fabrics.

Consider the difference between Screen Printing and Direct-to-Garment (DTG) printing. Screen printing is ideal for large runs of designs with a limited number of colors. It produces vibrant, durable prints with a distinct tactile feel. A skilled screen printer can create specialized effects like cracked prints, which mimic the look of an old, well-loved t-shirt. DTG, on the other hand, is like an inkjet printer for fabric, perfect for highly detailed, multi-color designs in smaller quantities. A proficient manufacturer will not only offer both but will also guide you on which method is best suited for your project's budget, volume, and aesthetic goals.

Embroidery is another area where expertise is paramount. Look for a factory that offers a range of options:

- Towel/Chenille Embroidery: This creates a raised, looped, and textured finish, commonly seen on varsity jackets and collegiate-style sweatshirts.

- Appliqué Embroidery: This involves stitching pieces of fabric onto a garment to create a layered design, often combined with traditional embroidery for outlines and details.

- 3D/Puff Embroidery: A technique where foam is placed under the embroidery stitching to create a raised, three-dimensional effect, perfect for bold logos.

The best private label clothing manufacturers will demonstrate a holistic understanding of how these different techniques interact with various fabrics. They will know, for instance, that a heavy embroidery design requires a stable, heavyweight fabric to prevent puckering and that a puff print application needs precise temperature control to achieve the desired effect without scorching the garment.

Heavyweight Fabrics and Construction

The foundation of any quality garment is the fabric itself. In streetwear, particularly for core items like hoodies and t-shirts, there is a significant emphasis on heavyweight materials. A premium hoodie is not just a piece of clothing; it is a substantial, almost architectural garment. The weight of the fabric—measured in grams per square meter (GSM)—is a key indicator of quality.

A capable manufacturer will have deep expertise in a range of fabric weights. For t-shirts, this might span from a standard 180gsm to a dense, structured 400gsm. For hoodies and sweatpants, the range typically falls between 300gsm and a truly substantial 600gsm French terry or fleece. When you are vetting a manufacturer, ask to see and feel samples across this spectrum. Do their 500gsm hoodies have the structure and hand-feel you expect? Is their heavyweight jersey cotton soft yet durable?

Their expertise should extend to construction as well. A heavyweight garment requires robust stitching, reinforced seams, and pattern-making that accounts for the fabric's drape and structure. An oversized, boxy silhouette, for example, is not simply a larger version of a standard fit. It requires careful pattern engineering to ensure the shoulders drop correctly and the body maintains its shape without appearing sloppy. A manufacturer with experience in this area will be able to produce garments that are not only durable but also fit with intention.

2. Scrutinize Minimum Order Quantities (MOQ) and Production Scalability

After confirming a manufacturer's technical prowess, the next critical area of investigation concerns their production model. Specifically, you need to understand their policies on Minimum Order Quantities (MOQ) and their capacity to scale production as your brand grows. This is not just a matter of logistics; it is a fundamental aspect of your business strategy, directly impacting your financial risk, inventory management, and ability to respond to market demands. An ideal partner offers a model that is both flexible enough for the present and robust enough for the future.

The Strategic Value of a Flexible MOQ

For a startup or emerging streetwear brand, a high MOQ can be a death sentence. Being forced to order hundreds or thousands of units of an unproven design ties up precious capital and creates a significant risk of dead stock. This is why a manufacturer's willingness to offer a low or flexible MOQ is one of the most important signals of a true partnership mentality.

Look for private label streetwear manufacturers that offer MOQs in the range of 50–100 pieces per color per style. This model provides several strategic advantages:

- Market Testing: A low MOQ allows you to produce a small batch of a new design to test its appeal with your audience before committing to a larger production run. You can "float" a new graphic hoodie or a new colorway of your core t-shirt and gather real-world sales data.

- Reduced Financial Risk: By ordering smaller quantities, you minimize your upfront investment and reduce the financial impact if a particular design does not sell as well as expected. This frees up capital that can be reinvested in marketing or developing other products.

- Increased Agility: The streetwear market moves at lightning speed. A low MOQ enables you to be more agile, quickly introducing new, trend-responsive "drops" or limited-edition capsules to keep your brand fresh and your audience engaged.

- Wider Product Assortment: Instead of investing your entire budget into one or two designs, a flexible MOQ allows you to produce a wider variety of styles, giving your customers more choice and increasing the perceived breadth of your collection.

When discussing MOQs, be sure to clarify the specifics. Is the 50-piece minimum for a simple logo application on a stock blank, or does it apply to a fully custom "cut and sew" garment with specialized washes and prints? A partner like Groovecolor, for example, explicitly offers this 50-100 piece MOQ for custom development, indicating a production system that is genuinely designed to support emerging brands (m.groovecolor.com, 2025).

Planning for Growth: The Importance of Scalable Capacity

While a low MOQ is crucial for getting started, it is only one half of the equation. The other half is the manufacturer's ability to scale with you. What happens when your test run of 50 hoodies sells out in a day? Can your manufacturer quickly pivot to a bulk production run of 1,000 or 10,000 pieces while maintaining the same level of quality?

This is where you need to investigate their total production capacity. A factory with a monthly capacity of 300,000 pieces or more demonstrates that they have the infrastructure, workforce, and supply chain relationships to handle significant volume. Ask them about their largest production runs to date. Inquire about their use of Enterprise Resource Planning (ERP) systems. An ERP system integrates all facets of an operation, including planning, manufacturing, sales, and marketing. A manufacturer that uses an ERP system is better equipped to manage a coordinated material pool, forecast production timelines, and handle rapid reorders efficiently.

The ideal production model is one of "agile replenishment." This means the manufacturer can accommodate your initial small test orders and then seamlessly scale up to bulk production once you have market validation. This structure is the hallmark of a manufacturer that is not just looking for a quick order but is invested in your long-term growth strategy. They understand that your success is their success.

Below is a table comparing different MOQ models you might encounter when vetting private label streetwear manufacturers.

| MOQ Model | Typical Quantity | Best For | Pros | Cons |

|---|---|---|---|---|

| Flexible / Low MOQ | 50-100 pcs/color | Startups, Market Testing, Limited Drops | Low financial risk, High agility, Allows for wider product assortment | Higher cost per unit, May have limited customization options with some factories |

| Standard MOQ | 200-500 pcs/color | Growing Brands, Core Product Replenishment | Moderate cost per unit, Access to more customization, Good for proven sellers | Moderate financial risk, Requires confidence in the design's market appeal |

| High / Bulk MOQ | 1000+ pcs/color | Established Brands, Mass-Market Retail | Lowest cost per unit, Maximum production efficiency | High financial risk, Ties up significant capital, Risk of dead stock if trends shift |

This table illustrates the strategic trade-offs involved. While the lowest per-unit cost of a high MOQ model may seem appealing, the flexibility and risk mitigation offered by a low MOQ partner are often far more valuable for a brand navigating the volatile streetwear landscape.

3. Verify Quality Management Systems and Ethical Compliance

In the pursuit of creating a premium streetwear brand, the concepts of quality and ethics are not peripheral concerns; they are central to your brand's value proposition and long-term viability. A customer who invests in a high-end garment expects it to be impeccably made and, increasingly, to have been produced under responsible conditions.

Therefore, a rigorous assessment of a potential manufacturer's quality management systems and ethical compliance certifications is a non-negotiable step in the vetting process. This inquiry demonstrates your own commitment to excellence and responsible sourcing.

The Foundation of Consistency: ISO 9001

When a manufacturer claims to have a quality management system, the gold standard for verification is ISO 9001 certification. ISO 9001 is an internationally recognized standard that sets out the criteria for a quality management system. It is not a product standard, but a process standard. This means it certifies that the factory has a systematic approach to managing its processes to consistently meet customer and regulatory requirements.

A manufacturer operating in accordance with ISO 9001 principles will have documented procedures for every stage of production. This includes:

- Raw Material Inspection: Checking incoming fabrics for defects, correct weight (GSM), and color consistency.

- In-Process Control: Implementing quality checkpoints throughout the cutting, sewing, printing, and washing stages.

- Final Inspection: A thorough examination of the finished garment to ensure it meets all specifications in the tech pack, from measurements and stitching to print placement and color accuracy.

Ask potential private label streetwear manufacturer if they are ISO 9001 certified or if they operate according to its core principles. A factory that has invested in this level of process standardization is demonstrating a serious commitment to quality and consistency. They are more likely to have systems in place to catch potential issues early, proactively manage risks, and deliver a final product that aligns with your expectations, order after order. This systematic approach is what separates professional manufacturing from amateur operations and is essential for scaling a brand without sacrificing quality.

Beyond the Basics: Understanding SMETA 4P vs. BSCI

In today's market, ethical compliance is as important as quality control. Consumers, particularly the globally-aware audience for streetwear, are increasingly concerned with the social and environmental impact of their purchases. Aligning your brand with a manufacturer that upholds high ethical standards is not just good morals; it is good business.

Many factories will mention that they are "BSCI audited." The Business Social Compliance Initiative (BSCI) is a common industry standard that focuses primarily on labor standards and workplace health and safety. While a BSCI audit is a positive sign, a more comprehensive and rigorous certification to look for is SMETA 4P.

SMETA stands for Sedex Members Ethical Trade Audit. It is one of the most widely used ethical audit formats in the world. The "4P" refers to its four-pillar structure, which provides a much more holistic assessment of a manufacturer's operations.

Let's break down the difference in the table below.

| Audit Pillar | BSCI (Amfori) | SMETA 4-Pillar | Why It Matters for a Premium Brand |

|---|---|---|---|

| Labour Standards | Yes | Yes | Ensures fair wages, working hours, and no child or forced labor. This is the baseline for ethical production. |

| Health & Safety | Yes | Yes | Guarantees a safe and healthy working environment for all employees, reducing accidents and improving morale. |

| Environment | Limited | Yes (Dedicated Pillar) | Assesses the factory's environmental management, including waste disposal, water usage, and emissions. Crucial for sustainability claims. |

| Business Ethics | No | Yes (Dedicated Pillar) | Audits the factory's policies on bribery, corruption, and integrity. This signals a trustworthy and transparent business partner. |

As the table illustrates, SMETA 4P goes significantly further than a standard BSCI audit. The inclusion of dedicated pillars for the environment and business ethics demonstrates a higher level of commitment to responsible manufacturing.

A manufacturer with SMETA 4P certification is not just meeting the minimum requirements; they are actively managing their environmental footprint and conducting their business with integrity.

For a premium streetwear brand, this is a powerful differentiator. It allows you to make credible claims about your commitment to sustainability and ethical sourcing. It also provides assurance that you are partnering with a reliable and transparent organization, reducing the risk of your brand being associated with a labor or environmental scandal.

When vetting private label streetwear manufacturers, ask if they are SMETA audited and if they can share their audit report via the Sedex platform. A willingness to be transparent about their compliance is a strong indicator of a trustworthy partner.

4. Assess Communication, Process Transparency, and Tech Pack Handling

A manufacturing partnership is, at its core, a relationship built on communication. The most technically advanced factory in the world will be a source of constant frustration if they are difficult to communicate with, lack transparency in their processes, or fail to properly interpret your creative vision. Evaluating a manufacturer's communication style and their method for handling technical specifications is therefore a crucial step in predicting the success and smoothness of your future collaboration. It is about finding a partner who not only hears your instructions but truly understands your intent.

The Tech Pack: Your Architectural Blueprint

Think of a technical pack, or "tech pack," as the architectural blueprint for your garment. It is the single most important document you will provide to your manufacturer. A comprehensive tech pack should leave no room for ambiguity and typically includes:

- Technical Flats: Detailed, two-dimensional drawings of the garment from the front, back, and side.

- Construction Details: Specific instructions on stitching, seam types, and any special construction methods.

- Bill of Materials (BOM): A complete list of all materials needed, including main fabric, lining, ribs, thread, buttons, zippers, and labels.

- Measurements and Graded Spec Sheet: Precise measurements for a sample size, along with the "grade rules" for scaling the measurements up and down for your full size range.

- Artwork and Embellishment Details: High-resolution files for all prints and embroidery, with exact placement, dimensions, and color codes (e.g., Pantone values).

- Labeling and Packaging Instructions: Details on the placement of main labels, care labels, and hangtags, as well as instructions for folding and bagging the final product.

The way a potential manufacturer responds to your tech pack is incredibly revealing. A subpar factory might simply glance at it and give you a price. A true partner, however, will treat it as the beginning of a dialogue. They will conduct a thorough feasibility review. Their team of pattern makers and production experts will analyze every detail, looking for potential issues before they become costly problems.

From Instruction to Collaboration: The Value of Expert Feedback

A great manufacturer does not just passively follow instructions. They actively collaborate with you to optimize your design for production. This is where you can clearly distinguish a transactional supplier from a strategic partner. During the tech pack review, a good partner will provide professional recommendations and ask clarifying questions, such as:

- "The heavy embroidery you've specified on this lightweight jersey may cause puckering. We recommend adding a stabilizer backing or considering a slightly heavier fabric. Would you like us to prepare samples of both options?"

- "Your pattern structure for this oversized hoodie is good, but based on our experience, increasing the drop shoulder by two centimeters will create a more balanced silhouette. We can adjust the pattern and show you in the first sample."

- "The Pantone color for your screen print is achievable, but it may look slightly different on the acid-washed fabric. We recommend doing a small color swatch test for your approval before we proceed with sampling the full garment."

This kind of proactive, execution-focused feedback is invaluable. It demonstrates that the manufacturer is thinking critically about your project and leveraging their experience to improve the final outcome. They are focused on resolving potential issues at the earliest possible stage, which saves you time, money, and frustration.

This collaborative approach minimizes the number of sample revisions needed and dramatically reduces the risk of errors during bulk production. It transforms the relationship from a simple client-vendor dynamic into a partnership where both parties are working towards the same goal: creating the best possible product.

When you are in the initial stages of talking to private label clothing manufacturers, send them a detailed tech pack for one of your more complex designs. Pay close attention to the quality and depth of their response. Do they ask intelligent questions? Do they offer thoughtful suggestions? Or do they just send back a number? Their response will tell you everything you need to know about their communication style and their potential as a long-term partner.

5. Investigate Material Sourcing and Fabric Expertise

The fabric is the soul of a garment. It determines the product's hand-feel, its structure, its durability, and a significant portion of its perceived value. A streetwear brand that aims for a premium positioning cannot afford to compromise on materials.

Consequently, a thorough investigation into a manufacturer's fabric expertise and sourcing capabilities is a fundamental part of the vetting process. You are looking for a partner who is not just a sewer of garments but a connoisseur of textiles, capable of providing a diverse palette of high-quality materials from which to create your collection.

The Importance of a Diverse Fabric Library

A top-tier manufacturer should act as your gateway to a world of textiles. They should possess a well-developed and extensive fabric library, offering a wide range of options that you can see, touch, and test. When you visit their showroom or request sample swatches, you should be presented with a diverse selection, particularly in the materials that are core to streetwear.

Look for a factory that offers a multitude of options in cotton and French terry, the workhorse fabrics of the genre. Their library should include:

- A Spectrum of Weights (GSM): As discussed earlier, a manufacturer's ability to offer fabrics across the full 180-600gsm range is critical. They should have readily available options for lightweight summer t-shirts, mid-weight custom streetwear hoodies, and heavy, structured winter hoodies.

- Different Cotton Varieties: Beyond just weight, they should be able to source different types of cotton, such as combed cotton (for softness and strength), organic cotton (for sustainability), and blended cottons (for specific performance characteristics like stretch or moisture-wicking).

- French Terry Variations: French terry is characterized by its looped interior. A good supplier will have options with different loop sizes and densities, affecting the fabric's absorbency and texture, as well as fleece-backed versions for added warmth and softness.

A manufacturer with a library of over 200 premium fabric options, like Groovecolor, demonstrates a deep and established network of textile mills. This not only gives you more creative freedom but also indicates that they have the sourcing power to secure consistent, high-quality materials for your bulk production runs.

Expertise in Customization and Sustainable Sourcing

Beyond their existing library, the best private label streetwear manufacturers will also offer custom fabric development. Perhaps you are looking for a specific heather grey with a unique nep texture, or you want to develop a proprietary blend that offers a particular combination of softness and structure. A manufacturer with strong relationships with textile mills can work with you to create a fabric that is exclusive to your brand, providing a powerful competitive advantage.

Furthermore, in an era of increasing environmental consciousness, a manufacturer's ability to source sustainable materials is a crucial consideration. Inquire about their access to certified materials like:

- GOTS (Global Organic Textile Standard) Certified Cotton: This is the world's leading standard for organic fibers, ensuring that the entire production process, from harvesting to manufacturing, meets strict environmental and social criteria.

- Recycled Polyester and Cotton: Many advanced mills now produce high-quality fabrics from post-consumer or post-industrial waste, reducing landfill burden and conserving resources.

- OEKO-TEX® Certified Fabrics: An OEKO-TEX® certification guarantees that the fabric has been tested for and is free from a long list of harmful substances, ensuring it is safe for human health.

A manufacturer that proactively offers these sustainable options and understands the certification processes demonstrates a forward-thinking approach and a commitment to responsible manufacturing. They can help you build a brand that is not only stylish and well-made but also aligned with the values of a modern, conscious consumer. This commitment to strengthening material safety and sustainability from the source is a hallmark of a manufacturer that is prepared to help you achieve your long-term environmental and social responsibility goals.

6. Analyze Production Timelines and Logistical Efficiency

In the fast-paced world of streetwear, timing is everything. A collection that launches a month too late can miss its cultural moment entirely. The ability to move from a design concept to a finished product in a timely and predictable manner is a significant competitive advantage. Therefore, a critical analysis of a manufacturer's production timelines and overall logistical efficiency is an essential part of your vetting process. You need a partner whose operational rhythm can match the tempo of the market.

Deconstructing the Production-to-Market Calendar

The journey from a finalized tech pack to having bulk goods in your warehouse can be a long one. In a typical, unoptimized apparel supply chain, this process can stretch from 90 to 120 days. Let's break down the common stages:

- Sampling: This stage, which includes creating the first sample and any subsequent revisions, can take anywhere from 2 to 4 weeks.

- Pre-Production: Once the sample is approved, the factory needs to source and receive the bulk fabric and prepare its production lines. This can take another 2 to 3 weeks.

- Bulk Manufacturing: The actual cutting, sewing, printing, and finishing of your full order. For a moderately sized order, this typically takes 4 to 6 weeks.

- International Shipping: This is a major variable. Shipping by sea freight is cost-effective but slow, often taking 4 to 6 weeks to reach North America or Europe from Asia. Air freight is much faster (around 1 week) but is significantly more expensive.

This extended timeline can create major challenges for a streetwear brand. It requires you to finalize your designs months in advance, making it difficult to react to emerging trends. It also ties up your capital for a long period before you can start generating revenue from the products.

The Competitive Advantage of a Compressed Timeline

This is where an integrated, highly efficient manufacturer can provide a game-changing advantage. A factory that has optimized its internal processes can significantly compress the stages that are under its direct control. Look for private label clothing manufacturers that can demonstrate a more streamlined timeline.

For instance, a manufacturer with a well-managed system might complete the sampling process, including minor revisions, in approximately 2 to 3 weeks. More importantly, their bulk production time for core streetwear items like t-shirts, hoodies, and sweatpants should be closer to 3 to 4 weeks, depending on the order's complexity and volume.

How is this possible? This efficiency is not magic; it is the result of a deliberate and integrated manufacturing model. Key elements that contribute to a faster turnaround include:

- Pre-aligned Fabric Pools: A factory that maintains a ready stock of its most commonly used high-quality fabrics can begin production almost immediately after sample approval, eliminating the weeks-long wait for fabric to be milled and delivered.

- In-House Capabilities: A manufacturer that has its own in-house facilities for washing, printing, embroidery, and embellishment can coordinate these processes much more efficiently than a factory that has to outsource them to various third-party vendors. This reduces logistical complexity and saves valuable time.

- Standardized Workflows: An experienced streetwear manufacturer will have developed standardized and optimized workflows specifically for the types of garments you are producing. They have already figured out the most efficient way to produce a heavyweight, acid-washed hoodie, allowing them to move from one order to the next with minimal setup time.

While the total end-to-end lead time will always be dependent on your choice of shipping method, a manufacturer's ability to shorten the factory-side production window is a powerful asset. It gives you more flexibility in your launch planning, allows you to react more quickly to market feedback for reorders, and provides you with a more predictable and reliable calendar for your seasonal drops. When vetting potential partners, ask them for a detailed, stage-by-stage breakdown of their typical production timeline. A partner who can confidently and credibly promise a faster-than-average turnaround is offering you a direct competitive edge.

7. Look for a True Growth Partner Beyond Manufacturing

The final point on our checklist transcends the technical and logistical aspects of production. It invites you to look for something more profound: a manufacturer that sees itself not as a mere vendor hired to perform a task, but as a strategic partner invested in your brand's growth journey. This is the difference between a relationship that is purely transactional and one that is transformational. A true growth partner offers value that extends far beyond the factory floor, providing insights and support that can help you navigate the complexities of the market and build a more resilient and successful brand.

Value-Added Services: Content and Market Rhythm Support

In the digital age, a brand is not just its products; it is also its content. The way you present your products online—through compelling photography, engaging videos, and a consistent visual narrative—is just as important as the quality of the products themselves. Recognizing this, some forward-thinking private label clothing manufacturers have begun to offer value-added services designed to support their clients' marketing efforts.

For their long-term partners, a manufacturer like Groovecolor might offer professional product photography and short-form video services. This can be an incredible asset for a growing brand. It ensures that your products are showcased in the best possible light, with high-quality, consistent imagery that can be used across your e-commerce site, social media channels, and digital ad campaigns. It saves you the time and expense of organizing your own photoshoots and ensures that your visual content is ready to go as soon as your products are.

Beyond content creation, a deeply experienced manufacturer can also offer invaluable advice on market rhythm. Having worked with hundreds of brands, they have a unique perspective on what works. They can provide channel-specific recommendations for launching new products, suggest optimal timing for seasonal drops, and offer data-driven insights on replenishment strategies for your best-selling items. This kind of strategic guidance can help you optimize your sales performance and avoid common pitfalls, transforming your manufacturer from a simple producer into a trusted advisor.

The Bedrock of Partnership: Reliability and Trust

Ultimately, the foundation of any long-term partnership is trust. This trust is built over time through consistent performance, transparent communication, and a demonstrated commitment to your brand's success. When you are vetting a potential partner, look for indicators of this reliability.

One of the most powerful indicators is a high client retention rate. A manufacturer that can state that 90% of its clients place repeat orders is sending a clear signal that they consistently deliver on their promises. An even more compelling statistic is the longevity of their relationships. A factory where 30% of its clients have maintained partnerships for over a decade is demonstrating an extraordinary level of reliability and client satisfaction. These are not just numbers; they are testaments to the manufacturer's ability to build and sustain trust.

Look for a manufacturer that has a reputation built on responsiveness, reliability, and long-term accountability. They should be a primary export manufacturing partner for other globally recognized streetwear labels, with a proven track record of shipping products to major markets around the world. This indicates that they have navigated the complexities of international logistics and compliance and have earned the confidence of other serious players in the industry.

Choosing a manufacturing partner is one of the most significant decisions you will make as a brand founder. By looking beyond the per-unit cost and seeking a partner that offers technical mastery, a flexible and scalable production model, a commitment to quality and ethics, transparent communication, and a genuine investment in your growth, you are not just sourcing production. You are building a foundational pillar for your brand's future, an alliance that will empower you to create, innovate, and thrive in the ever-evolving world of streetwear.

Frequently Asked Questions (FAQ)

What is the most important factor when choosing a private label streetwear manufacturer?

While cost is a consideration, the most important factor is alignment. This means finding a manufacturer whose technical capabilities, quality standards, and production model align with your brand's specific needs and long-term vision. For a premium streetwear brand, this often points to a partner with specialized skills in relevant aesthetics (like vintage washes), a flexible MOQ, and robust quality certifications like SMETA 4P.

What is a reasonable MOQ for a startup streetwear brand?

A reasonable Minimum Order Quantity (MOQ) for a startup is typically between 50 and 100 pieces per style/color. This allows you to test new designs in the market with minimal financial risk and avoid being burdened with large amounts of unsold inventory. Be wary of manufacturers who will only work with MOQs of 500 or 1,000 pieces, as this model is better suited for established brands with proven sales data.

How is SMETA 4P certification different from a BSCI audit?

BSCI (Business Social Compliance Initiative) primarily focuses on labor standards and workplace health and safety. SMETA 4-Pillar is more comprehensive, covering those two areas plus two additional pillars: Environmental Management and Business Ethics. For a brand concerned with sustainability and corporate responsibility, a SMETA 4P certification provides a higher level of assurance that the manufacturer operates ethically and responsibly across its entire business.

Why is a manufacturer's feedback on my tech pack so important?

A tech pack is your design's blueprint. A good manufacturer's expert feedback on it is crucial because they can identify potential production issues before they become expensive mistakes. They might suggest a more suitable fabric for a particular print technique or a small pattern adjustment to improve the garment's fit. This collaborative approach saves time, reduces the need for multiple sample revisions, and results in a better final product.

How much does it cost to manufacture a hoodie with a private label streetwear manufacturer?

The cost can vary dramatically based on several factors: fabric weight (GSM), complexity of design (e.g., heavy embroidery, multiple washes), order quantity (MOQ), and the manufacturer's location and quality level. A heavyweight (500gsm), intricately embroidered hoodie from a premium, ethically certified factory might cost anywhere from $25 to $39+ per unit, whereas a simpler, mid-weight hoodie produced in a larger quantity could be significantly less. It is essential to get detailed quotes based on a comprehensive tech pack.

Should I choose a manufacturer in China or another country like Portugal or Turkey?

Each region has its strengths. China, particularly in areas like Dongguan, is renowned for its highly specialized streetwear expertise, advanced technical capabilities (especially in washes and complex embellishments), and scalable infrastructure. Portugal is known for high-quality jersey and fleece production with a premium feel. Turkey has a strong textiles industry and is geographically closer to European markets. For brands focused on complex, culturally specific aesthetics like Y2K or authentic vintage looks, the deep technical expertise and integrated supply chains in China often provide a distinct advantage.

A Final Reflection on Partnership

As we draw our detailed examination to a close, a central theme emerges with compelling clarity: the selection of a manufacturing partner is an act of brand-building. It is a decision that resonates through every fiber of your product and every interaction with your customer. The path to creating a lasting streetwear brand is not paved with transactional relationships and corner-cutting compromises. It is built upon a foundation of strategic, empathetic, and reliable partnerships.

The checklist we have navigated is more than a set of procedural steps; it is a framework for cultivating a specific kind of relationship—one grounded in mutual respect, shared goals, and a collective pursuit of excellence. The right partner does not just make your clothes; they help you build your legacy.

References

- Coface. (2024). Reconfiguration of global clothing supply: Who will manufacture tomorrow's “made in China” products? coface.com

- Fortune Business Insights. (2024). Streetwear Market Size, Share & COVID-19 Impact Analysis. fortunebusinessinsights.com

- Groovecolor. (2025). About Groovecolor.

- Groovecolor. (2025). Customization.

- Groovecolor. (2025). Top 6 Chinese Custom Streetwear Manufacturers for E-commerce Brands. m.groovecolor.com

- International Organization for Standardization. (n.d.). ISO 9001:2015 Quality management systems — Requirements. ISO. https://www.iso.org/standard/62085.html

- Sedex. (n.d.). SMETA, the world's leading social audit. https://www.sedex.com/solutions/smeta-audit/

- Shenglu Fashion. (2024). China's Textile and Clothing Export: Latest Patterns and Trends (Updated August 2024). shenglufashion.com

- World Trade Organization. (2023). World Trade Statistical Review 2023.