Prints, Washes, Embroidery: Advanced Street Style Pants Customization Techniques

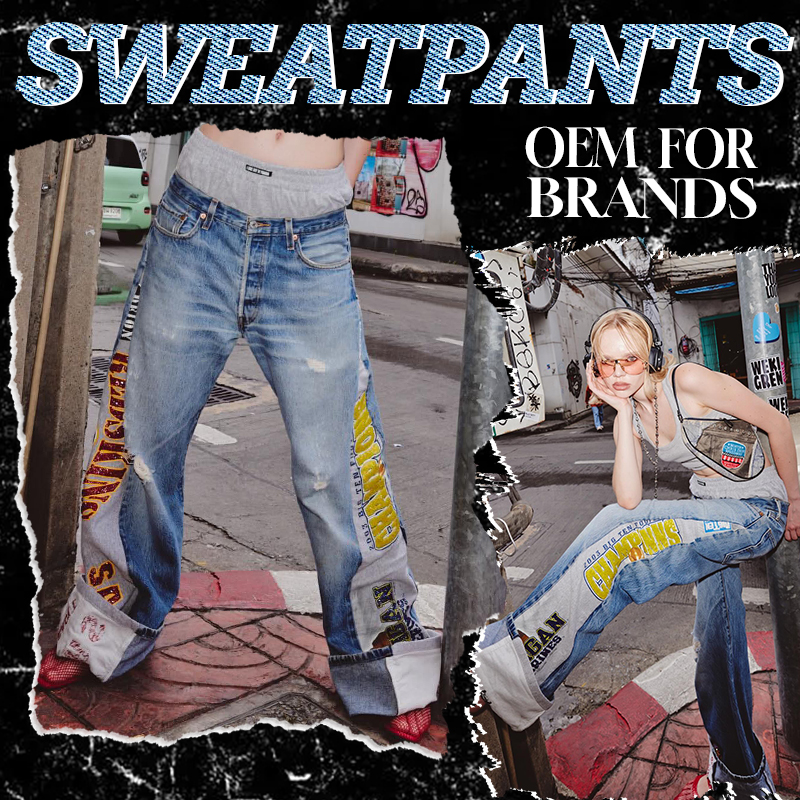

In the hyper-competitive landscape of modern streetwear, differentiation is no longer a luxury—it is the core engine of brand survival and growth. While trends in silhouettes and graphics may come and go, the ability to execute a unique, tangible vision through advanced customization is what separates fleeting hype from enduring brand equity. For established and growing streetwear brands, the conversation has shifted from simply placing a logo on a blank garment to mastering the intricate alchemy of prints, washes, and embroidery. This evolution demands a deeper understanding of how specialized techniques can transform a simple pair of street style pants into a statement piece that resonates with a discerning global audience.

However, scaling these complex creative visions from a single sample to a full production run introduces a host of challenges that many brands underestimate. The very processes that create unique, vintage-inspired aesthetics—such as acid washes, intricate embroidery, and multi-layered prints—are also the most susceptible to inconsistency, quality degradation, and production bottlenecks. This is where the manufacturing partnership becomes a critical strategic decision. The ability to deliver consistent quality at scale is not a given; it is the result of a purpose-built production infrastructure designed specifically for the nuances of streetwear. Manufacturers like Groovecolor, which have built their expertise around these complex processes, are structurally positioned to bridge the gap between a brand's creative ambition and the realities of bulk production, ensuring that every pair of pants delivered to the market is a true representation of the original design intent.

Key Takeaways for Streetwear Brands

- ▸ Advanced garment washing, digital patternmaking, and precision embroidery bring unique streetwear concepts to life and ensure every style stands out in the competitive global market.

- ▸ Efficient, scalable manufacturing processes allow brands to move quickly from market testing to bulk orders—without sacrificing quality or delivery times for US, UK, and EU brands.

- ▸ Access to a full spectrum of heavyweight fabrics (260-400gsm), vintage washes, and modern graphics options unlocks endless creative potential for premium street style pants collections.

- ▸ Comprehensive technical support and robust quality control systems help streetwear brands minimize risk and deliver top-tier products to the global market with batch-to-batch consistency.

Advanced Customization Techniques for Street Style Pants: Prints, Washes, Embroidery

Creating truly iconic street style pants requires a mastery of techniques that go far beyond basic cut-and-sew construction. For established streetwear brands, the ability to manipulate fabric surfaces through printing, washing, and embroidery is what defines a collection's unique identity and justifies a premium price point. These processes are not mere embellishments; they are narrative tools that can evoke a sense of nostalgia, convey a specific cultural message, or create a powerful visual statement. However, each technique comes with its own set of technical challenges and requires a deep understanding of how different materials will react. This section explores the most impactful customization techniques and how they can be leveraged to create standout street style pants.

The Art of the Print: From Bold Graphics to Subtle Textures

Printing is arguably the most direct way to imbue a garment with a brand's personality. In streetwear, prints are not just decorative; they are a form of communication, a way to connect with a subculture, or a canvas for artistic expression. The choice of printing technique can dramatically alter the final look and feel of the pants, from a crisp, vibrant graphic to a soft, vintage-inspired design.

Screen Printing

Direct-to-Garment (DTG) Printing

Puff Printing

Cracked and Distressed Prints

For heavyweight cotton or denim pants, screen printing provides a durable finish that can withstand repeated washing and wear. However, achieving a soft hand-feel can be challenging, and the setup costs for multi-color designs can be high, making it less suitable for small, highly detailed runs. DTG is particularly effective on 100% cotton fabrics, and because there are no screen setup costs, it is a viable option for small batches and one-off samples. The main drawback of DTG is that the colors can be less vibrant on dark fabrics, and the ink is not as durable as screen printing, especially on fabrics that will undergo heavy washing.

The Science of the Wash: Creating Depth, Texture, and Character

Washing is a transformative process that can completely alter the character of a pair of pants. In streetwear, washing is not just about cleaning the garment; it is a creative tool for achieving specific colors, textures, and finishes. The right wash can make a new pair of pants feel like a treasured vintage find, or it can create a unique, one-of-a-kind look that cannot be replicated with printing alone.

Acid Wash

Stone Wash

Enzyme Wash

When done correctly, acid washing can create a bold, edgy look that is synonymous with 80s and 90s street style. Stone washing is a versatile technique that can be used on a wide range of fabrics, including denim, twill, and heavyweight cotton. Enzyme washing is also less damaging to the fabric than stone washing, which can help to extend the life of the garment. Enzyme washing is an excellent choice for brands that want to create a vintage-inspired look without the environmental impact of traditional washing techniques.

The Craft of Embroidery: Adding a Touch of Luxury and Detail

Embroidery is a timeless technique that can add a touch of luxury and sophistication to any garment. In streetwear, it is often used to create detailed logos, intricate patterns, and custom patches that elevate the overall design of the pants. Unlike printing, which sits on the surface of the fabric, embroidery is physically stitched into the material, creating a durable, high-quality finish that will last for the life of the garment.

Flat Embroidery

3D Embroidery

Towel Embroidery (Chenille)

Applique

Quality Control in Street Style Pants Customization: Ensuring Consistency in Prints, Washes, and Embroidery

For any streetwear brand, the transition from a single, perfect sample to a bulk production run of thousands of units is the moment of truth. It is here that the brand's reputation is either solidified or compromised. In the world of advanced customization, where complex processes like acid washing, multi-layer printing, and intricate embroidery are the norm, the risk of inconsistency is magnified. A slight variation in dye concentration, a millimeter shift in print placement, or a subtle difference in embroidery density can result in a final product that fails to meet the brand's standards and the customer's expectations. This is why a robust, multi-stage quality control (QC) process is not just a best practice—it is a non-negotiable requirement for any manufacturer serious about producing high-quality streetwear.

A truly effective QC system is not a single checkpoint at the end of the production line; it is a comprehensive framework that is integrated into every stage of the manufacturing process, from raw material inspection to final packaging. This proactive approach allows for the early detection and correction of potential issues, preventing them from becoming systemic problems that can derail a production run and damage a brand's reputation [4]. For a manufacturer specializing in complex streetwear, this process must be even more rigorous, with a deep understanding of the unique challenges posed by each customization technique.

The 8-Step Quality Locking Mechanism

A world-class streetwear manufacturer operates on a system of continuous quality control, often referred to as a "quality locking mechanism." This system is designed to ensure that every garment produced is a faithful replica of the approved sample, both in terms of its physical construction and its aesthetic details. This process can be broken down into eight critical steps:

By implementing a rigorous, multi-stage quality control process, a specialized streetwear manufacturer can provide brands with the confidence that their creative vision will be executed with precision and consistency, from the first sample to the last pair of pants in a bulk production run. This commitment to quality is what ultimately builds a brand's reputation and fosters long-term customer loyalty. The principles of quality management, as outlined by standards such as ISO 9001:2015, provide a robust framework for establishing, implementing, and continually improving a quality management system (QMS) [6].

Material and Technique Pairing: Selecting Fabrics for Advanced Street Pants Customization

The foundation of any great pair of street style pants is the fabric. The choice of material not only dictates the garment's comfort, durability, and drape, but it also has a profound impact on how well it responds to advanced customization techniques. A heavyweight cotton may be the perfect canvas for a bold, vibrant print, while a rugged denim might be better suited for a vintage-inspired acid wash. For streetwear brands, understanding the interplay between fabric and technique is essential for creating a product that is both visually stunning and built to last.

A manufacturer with deep expertise in streetwear will have a curated library of fabrics that are specifically chosen for their ability to withstand the rigors of complex customization. This includes not just a wide range of weights and compositions, but also a deep understanding of how each fabric will behave when subjected to different printing, washing, and embroidery processes. This knowledge is critical for avoiding costly mistakes and ensuring that the final product lives up to the brand's creative vision. For brands looking to explore the full range of custom streetwear pants options, understanding these fabric-technique relationships is essential.

Heavyweight Cotton (260-400gsm): Heavyweight cotton is the go-to fabric for premium street style pants. Its dense, durable construction provides the perfect canvas for a wide range of customization techniques, from screen printing and DTG to intricate embroidery. The smooth surface of the fabric allows for crisp, clean prints, while its weight and structure provide the necessary support for heavy embroidery and applique. When it comes to washing, heavyweight cotton can withstand aggressive processes like stone washing and enzyme washing, which can be used to create a soft, vintage-inspired feel.

Cotton Twill: Cotton twill is a versatile fabric that is known for its distinctive diagonal weave. It is a durable, mid-weight fabric that is often used for cargo pants, chinos, and other utility-inspired styles. Twill is an excellent choice for embroidery and applique, as its tight weave provides a stable base for detailed stitching. It also takes well to a variety of washing techniques, including garment dyeing, which can be used to create a rich, saturated color, and enzyme washing, which can be used to soften the fabric and create a more relaxed, casual feel.

Denim: Denim is a timeless fabric that has been a staple of streetwear for decades. Its rugged construction and ability to develop a unique patina over time make it the perfect canvas for a wide range of distressing and washing techniques. Acid washing and stone washing are classic choices for creating a vintage-inspired look, while enzyme washing can be used to create a softer, more comfortable feel. Denim is also an excellent choice for embroidery and patch details, which can be used to add a touch of personality and customization to the garment.

Pairing Techniques with Fabrics: A Strategic Approach

The key to successful customization is not just choosing the right fabric and the right technique, but understanding how they will work together. A strategic approach to material and technique pairing can help to ensure that the final product is both visually cohesive and structurally sound.

By carefully considering the interplay between fabric and technique, streetwear brands can create a product that is not only visually stunning, but also built to last. This strategic approach to customization is what separates the brands that are simply following trends from those that are setting them. For brands looking to understand the full scope of cut-and-sew manufacturing for streetwear silhouettes, a deep understanding of material science is essential.

Bulk Production and Flexibility: Scaling Up Street Style Pants Customization

For a growing streetwear brand, the ability to scale production without sacrificing quality or creative integrity is a critical challenge. The journey from a small, highly controlled sample run to a large-scale bulk order is fraught with potential pitfalls, especially when dealing with complex customization techniques. A process that is manageable on a handful of garments can quickly become a logistical nightmare when applied to thousands of units. This is where the manufacturing partner's capacity for both scale and flexibility becomes paramount. A truly strategic partner is one that can not only handle large order volumes but can also adapt to the fast-paced, trend-driven nature of the streetwear market.

Achieving consistency in bulk production is the cornerstone of a successful scaling strategy. For a brand that has built its reputation on the quality of its products, any deviation from the approved sample can be a major blow to customer trust. This is particularly true for techniques like acid washing, where the chemical process can be difficult to control, and multi-layer printing, where precise registration is essential. A manufacturer with a deep understanding of these processes will have developed standardized workflows and rigorous quality control measures to ensure that every garment in a production run is a faithful replica of the original.

Ensuring Consistency in Bulk Production

Maintaining consistency across a large production run requires a combination of technical expertise, process control, and a commitment to quality at every stage of the manufacturing process. Here are some of the key strategies that a specialized streetwear manufacturer will employ to ensure batch-to-batch consistency:

The Importance of Flexible MOQs and Agile Production: In the fast-paced world of streetwear, the ability to react quickly to market trends is a major competitive advantage. A brand that can bring a new design from concept to market in a matter of weeks is far more likely to capitalize on a fleeting trend than one that is locked into a rigid, long-term production schedule. This is why a manufacturer's flexibility is just as important as its capacity for scale.

Strategic Flexible MOQs: A manufacturer that offers flexible Minimum Order Quantities (MOQs) can be a valuable partner for a growing streetwear brand. The ability to place smaller orders for new designs allows a brand to test the market without committing to a large, risky production run. Once a design has been validated and has proven to be a strong seller, the brand can then scale up to a larger bulk order. This approach to production allows a brand to be more agile and responsive to market feedback, while also minimizing the risk of being left with a large inventory of unsold product.

Rapid Replenishment: In addition to flexible MOQs, the ability to quickly replenish a successful product is another key aspect of agile production. A manufacturer with a streamlined, efficient production process can help a brand to capitalize on a hot-selling item by quickly producing a new batch of garments to meet customer demand. This ability to react quickly to sales data is what allows a brand to maximize its revenue and build momentum in the market. By partnering with a manufacturer that can offer both the capacity for scale and the flexibility for agile production, a streetwear brand can position itself for long-term growth and success.

How-To: Launching a Street Style Pants Collection with Advanced Customization

Launching a new collection of street style pants with advanced customization is a complex undertaking that requires careful planning, clear communication, and a strong partnership with the right manufacturer. For a brand that is committed to quality and creative expression, a well-executed launch can be a major catalyst for growth. This step-by-step guide outlines the key stages of the process, from initial design concept to final delivery, with a focus on how to successfully navigate the challenges of advanced customization.

Step 1: The Tech Pack - Your Manufacturing Blueprint

The tech pack is the single most important document in the apparel manufacturing process. It is a comprehensive set of instructions that tells the manufacturer everything they need to know to bring your design to life. A detailed, well-prepared tech pack is the foundation of a successful production run, as it minimizes the risk of misinterpretation and ensures that both the brand and the manufacturer are aligned on every detail of the design. For more guidance on this critical document, see how to prepare a production-ready tech pack.

For a pair of street style pants with advanced customization, the tech pack should include:

Step 2: Finding the Right Manufacturing Partner

Once you have a complete tech pack, the next step is to find a manufacturer that has the expertise and capabilities to execute your vision. When evaluating potential partners, it is important to look beyond just price and consider a range of factors:

Step 3: Sampling - Bringing Your Vision to Life

The sampling stage is where your design begins to take shape. It is a critical opportunity to test your design, refine your fit, and ensure that the manufacturer is able to execute your vision to your standards. The sampling process typically involves several stages:

Step 4 & 5: Bulk Production, Quality Control, and Logistics

Once the pre-production sample has been approved, the bulk production run can begin. This is where the manufacturer's commitment to quality and consistency is put to the test. A reputable manufacturer will have a rigorous quality control process in place to ensure that every garment in the production run meets the brand's standards. This includes inline QC checks during the production process, a final 100% inspection of all finished garments, and a final random inspection before the order is shipped.

The final stage of the process is logistics and delivery. This involves packing the garments, arranging for shipping, and clearing customs. A manufacturer with experience in international logistics can be a valuable partner in this stage, as they can help to ensure that your products are delivered to your warehouse on time and on budget. By following this step-by-step guide and partnering with the right manufacturer, you can successfully launch a collection of street style pants with advanced customization that will captivate your audience and elevate your brand to the next level.

Frequently Asked Questions for Advanced Customization for Street Style Pants

What are the top print techniques for custom street style pants?

When it comes to custom street style pants, the top printing techniques are screen printing, Direct-to-Garment (DTG), and puff printing. Screen printing is the industry standard for its durability and vibrant colors, making it ideal for bold logos and graphics on heavyweight fabrics like denim and cotton. DTG is perfect for highly detailed, full-color designs and photorealistic images, offering a soft hand-feel on cotton-based pants. For brands looking to add texture and a three-dimensional effect, puff printing is an excellent choice, creating a raised, tactile finish that is popular for Y2K-inspired and retro designs. The choice of technique should be guided by the design complexity, fabric type, and the desired aesthetic of the final product.

How do acid wash and stone wash create unique effects on pants?

Acid wash and stone wash are two key techniques for achieving a vintage, worn-in look on street style pants, particularly on denim. Acid washing uses pumice stones soaked in a chlorine-based bleaching agent to strip the color from the fabric in a non-uniform, marbled pattern, creating a high-contrast, edgy aesthetic synonymous with 80s and 90s street style. Stone washing, on the other hand, uses pumice stones to physically abrade the surface of the fabric, resulting in a softer, more subtle fade and a comfortable, lived-in feel. The choice between the two depends on the desired level of distressing and the overall aesthetic of the collection. Both techniques require a high level of expertise to control the process and achieve consistent results across a bulk production run.

What quality controls are critical for embroidery and patches on streetwear pants?

For embroidery and patches, the most critical quality controls are stitch density, thread tension, and placement accuracy. Stitch density ensures that the embroidery is full and rich, with no gaps or visible fabric underneath. Proper thread tension is crucial to prevent puckering or looping, which can ruin the appearance of the design. Placement accuracy is also essential, as even a slight deviation can throw off the balance of the entire garment. A reputable manufacturer will use digital embroidery machines and a multi-stage QC process to ensure that every embroidered detail is executed with precision and consistency. Additionally, the quality of the backing material and the thread itself should be inspected to ensure durability and colorfastness.

Can heavyweight fabrics support all advanced customization options for street style pants?

Yes, heavyweight fabrics, such as 260-400gsm cotton and denim, are generally the best choice for supporting a wide range of advanced customization options. Their durable construction provides a stable base for intricate embroidery and applique, and their smooth surface is an ideal canvas for both screen printing and DTG. Additionally, heavyweight fabrics are robust enough to withstand aggressive washing techniques like acid washing and stone washing without compromising the integrity of the material. This makes them a versatile and reliable choice for brands that want to create a high-quality, highly customized product that will stand the test of time. The key is to work with a manufacturer that understands the specific requirements of each fabric-technique combination.

How does Groovecolor ensure batch consistency for complex street style pants orders?

Groovecolor ensures batch consistency through a rigorous, 8-step quality locking mechanism that is integrated into every stage of the production process. This includes raw material inspection using AI-powered fabric scanners, fabric pre-treatment for dimensional stability, precision cutting with automated laser technology, inline QC during production, detailed process inspection for each customization technique (prints, washes, embroidery), a 100% final inspection of every garment, pre-packing QC, and a final random inspection based on AQL international standards. By implementing this comprehensive quality control system, Groovecolor can minimize variations and ensure that every pair of pants in a bulk production run is a faithful replica of the approved sample, even for the most complex designs involving multiple customization techniques.

References

- Coats Group. "Denim Wash." https://www.coats.com/en-us/info-hub/denim-wash/

- Tolkar. "Exploring Stone Wash: A Unique Technique in Textile Finishing." https://www.tolkar.com/blogs/exploring-stone-wash-a-unique-technique-in-textile-finishing/

- Wikipedia. "Enzyme washing." https://en.wikipedia.org/wiki/Enzyme_washing

- QIMA. "Garment Quality Control & Inspection Procedures." https://blog.qima.com/inspection/garment-quality-inspection-procedures

- AQI Service. "General quality requirement for Embroidery and Printing in Apparel." https://blog.aqiservice.com/quality-requirement-for-embroidery-and-printing/

- International Organization for Standardization. "ISO 9001:2015 - Quality management systems - Requirements." https://www.iso.org/standard/62085.html

- Sedex. "SMETA Audit: The Global Standard for Social Audits." https://www.sedex.com/solutions/smeta-audit/