OEM Jacket Manufacturing Guide for Streetwear and Fashion Brands

OEM Jacket Manufacturing Guide for Streetwear and Fashion Brands

In today’s streetwear and fashion landscape, a jacket is more than outerwear—it's a statement of quality, culture, and brand credibility. The right OEM jacket manufacturer can transform creative vision into premium product, while the wrong choice risks delays, quality issues, and reputational damage. This in-depth guide provides actionable insights for established brands seeking to navigate the complexities of OEM jacket manufacturing in 2025 and beyond.

Key Takeaways for Streetwear Brands

- ▸ Leading OEM jacket manufacturers empower brands to create high-performance, on-trend pieces with full creative control and rapid market entry.

- ▸ Quality assurance, transparent supply chains, and scalable production are non-negotiable for reputation and growth.

- ▸ A strong focus on sustainability and ethical practices is essential to meet consumer and regulatory expectations.

- ▸ Adoption of advanced technologies—like digital patterning, AI inspection, and automation—guarantees efficiency and consistent results.

Why Choosing the Right OEM Jacket Manufacturer Is Critical for Your Brand's Reputation

Selecting an OEM partner is a strategic brand move, not just a sourcing decision. Jackets often serve as flagship products, requiring precise construction, technical features, and durable materials. Top-tier OEMs employ advanced QC, multi-stage inspections, and certifications like ISO 9001 to minimize defects and maximize reliability. Brands also benefit from customizable designs, sustainable options, and transparent, ethical production. A robust OEM relationship reduces returns, ensures market relevance, and builds consumer trust—critical in an era where over 75% of buyers value both quality and ethical sourcing.

What Distinguishes Leading OEM Jacket Manufacturers from Generic Suppliers?

Top OEM jacket manufacturers differ from generic suppliers in several core dimensions: Full design control—true OEMs build directly from client tech packs, enabling total brand vision.

Material quality—premium partners use certified, sustainable fabrics such as recycled polyester, waterproof laminates, and high-grade insulation, tested for durability and performance. Customization and innovation—industry leaders offer rapid prototyping, design consultations, and advanced features like laser-cut ventilation, reflective elements, and seamless bonding. Sustainability and compliance—ethical labor, OEKO-TEX/BSCI certifications, and environmental responsibility are standard.

Production scalability—flexible MOQs (50–800 units), fast lead times, and documented references support growth and reliability. Generic suppliers, in contrast, often lack deep technical expertise, offer limited customization, and pose risks in consistency or compliance.

How Do OEM Jacket Manufacturers Guarantee Fit, Consistency, and Quality at Scale?

Guaranteeing fit and quality across thousands of units requires structured processes and advanced technology. Patternmaking and tech packs—OEMs invest in digital patterning and grading for ergonomic fits, aligned to global sizing standards and diverse consumer profiles. Material inspection—fabrics and trims undergo lab testing for strength, weather resistance, and colorfastness before cutting.

Sample development—multiple prototypes are fitted and stress-tested to ensure alignment with the brand’s vision and technical specs. Automated cutting and assembly—laser-guided or AI-assisted machinery ensures accuracy and reduces waste. Quality control—inline monitoring, ISO-based AQL sampling, and data analytics identify defects before they scale. Final inspection and packaging—every unit is checked for fit, appearance, and functionality, with packaging designed for protection and branding. These systems allow OEMs to deliver reliable, scalable results, minimizing costly returns and supporting high-volume drops.

Which Fabric and Finish Options Are Essential for Modern Streetwear Jackets?

Modern streetwear jackets demand a mix of style, performance, and sustainability: natural fabrics such as cotton, denim, and wool blends for classic looks and comfort; technical materials like nylon, ripstop, and recycled polyester for windbreakers, puffers, and utility jackets, often treated for water resistance or UV protection; sustainable innovations including vegan leather, organic cotton, biodegradable synthetics, and recycled fills. Key finishes include acid and enzyme washes for vintage effect, waterproof/breathable coatings, quilted and padded textures, reflective and matte elements, custom embroidery, and antibacterial treatments. The right OEM offers access to a broad materials library, seasonal updates, and can advise on grammage, functionality, and trend alignment.

What Customization Capabilities Define World-Class OEM Jacket Manufacturing?

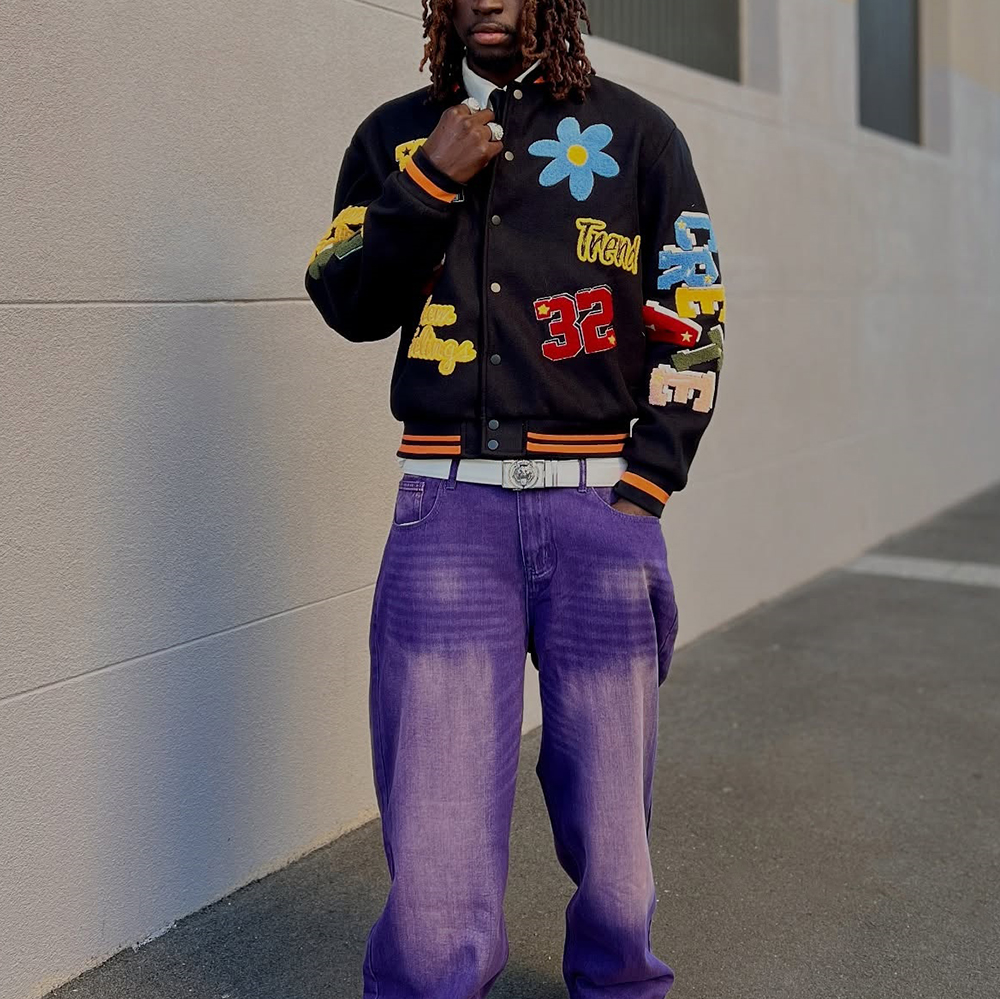

Industry-leading OEMs offer flexible prototyping, supporting custom patterns, silhouettes (bomber, varsity, puffer, techwear), and rapid virtual sampling. Material diversity includes a vast library of sustainable and performance fabrics, with global certifications. Branding and details encompass embroidery, patches, color blocking, reflective prints, branded tags, and custom trims for elevated identity. Inclusive sizing ranges from XS to 5XL, plus tall/oversized variants, to meet modern market needs.

Low MOQs and high capacity allow both market-testing and large bulk runs, often with lead times about 2-3 weeks for sampling and 3-4 weeks for production. Tech features include smart elements (heating, biometric sensors), seamless construction, and custom hardware. These strengths enable true differentiation and commercial flexibility for brands of all scales.

How Does Technology and Automation Reshape OEM Jacket Production?

Automation is revolutionizing OEM jacket manufacturing. Fabric cutting uses computerized laser systems that read digital patterns, ensuring precision and material efficiency. Sewing and assembly now leverage robotics and vision systems to automate complex seams, button attachment, and embroidery, improving speed and accuracy. Quality assurance is driven by AI inspection of every piece, catching inconsistencies or defects.

Automated presses create crisp lines and consistent quality, while IoT integration monitors workflow in real time. Logistics and tracking are streamlined with digital dashboards and QR-enabled traceability, offering transparency from factory to warehouse. The result is faster turnaround, reduced labor costs, higher consistency, and eco-friendly operation, though expert oversight remains crucial for creativity and excellence.

What Procurement Teams Should Demand from OEM Jacket Suppliers in 2025 and Beyond

Modern procurement teams need suppliers who demonstrate sustainability through GOTS, OEKO-TEX, or similar certifications; use recycled/biodegradable materials; and support circularity. Ethical labor practices, third-party audits, and compliance with global standards are non-negotiable. Suppliers should invest in AI, 3D printing, smart fabrics, and automation for innovation and supply chain transparency.

Supply chain agility—nearshoring, flexible MOQs, multi-country sourcing, and robust risk management—has become a must. Regulatory compliance, digital product passports, ESG reporting, and traceable emissions data should be standard. Seek partners who offer strategic design, compliance, and innovation—not just price negotiation—to ensure brand resilience amid rapid change.

How to Compare OEM Jacket Manufacturers: Side-by-Side Table

Frequently Asked Questions

What is the typical MOQ for custom OEM jackets?

Most top OEMs offer flexible MOQs from 50–100 units per color for established brands, enabling market testing before large-scale production.

How do I verify an OEM’s technical capabilities?

Look for process documentation, real client case studies, quality certifications, and references. Visiting the factory or requesting sample runs is best practice.

What is the average lead time from sampling to delivery?

Sample development typically takes 2-3 weeks; bulk production 3-4 weeks, depending on complexity, material sourcing and volume.

What are the benefits of automation in OEM jacket manufacturing?

Automation accelerates production, improves consistency, reduces costs, and allows greater customization—but still requires expert oversight to maintain quality and creativity.