How Streetwear Brands Can Customize Cargo Pants and Stand Out in a Saturated Market?

How Streetwear Brands Can Customize Cargo Pants and Stand Out in a Saturated Market

In the ever-evolving world of streetwear, how can a brand carve out its own space among countless competitors? The answer may lie in a meticulously crafted pair of cargo pants. Cargo pants, a classic item originating from military uniforms and rising to prominence during the 90s and Y2K eras, are no longer merely a symbol of functionality. They have become the ultimate canvas for brand storytelling, cultural expression, and design innovation. For streetwear brands seeking uniqueness and market resonance, mastering the art of customizing cargo pants means seizing the key to building a deep emotional connection with consumers. From the texture of the fabric to the structure of the pockets, from the quality of the hardware to the patterns of the wash, every detail is an extension of the brand's spirit. However, transforming a unique design concept into a high-quality, scalable product is a path fraught with challenges. Supply chain instability, the complexity of quality control, and the pitfalls of mass production are real-world problems every brand founder must face. This article will delve into how streetwear brands can create iconic products with a distinct identity by mastering every aspect of cargo pants customization, from fabric engineering and silhouette innovation to complex washing techniques. More importantly, we will reveal how choosing the right manufacturing partner, such as Groovecolor or other excellent cargo pants manufacturers, can be the decisive factor in a brand overcoming production challenges, realizing its creative vision, and ultimately achieving success in a fiercely competitive market. This is not just about creating a pair of pants; it is about building a brand's future.

1. The Resurgence of Cargo Pants: Why They Are the Cornerstone of Streetwear

The fashion vitality of cargo pants demonstrates an extraordinary resilience that few other garments can match. Their history can be traced back to early 20th-century military apparel, designed specifically to provide soldiers with durability and practicality in the harshest of conditions. The signature large pockets were engineered to carry maps, ammunition, and personal items, making them an indispensable part of military uniforms across the globe. This purely functional design, born out of necessity, inadvertently laid the groundwork for its future fashion evolution. After World War II, cargo pants gradually transitioned from the battlefield to civilian life, becoming the preferred choice for outdoor enthusiasts, hikers, and blue-collar workers who appreciated their rugged construction and practical storage solutions. However, it was the youth subcultures of the 90s and early 2000s, known as the Y2K era, that truly propelled them to the forefront of fashion and transformed them into a cultural phenomenon.

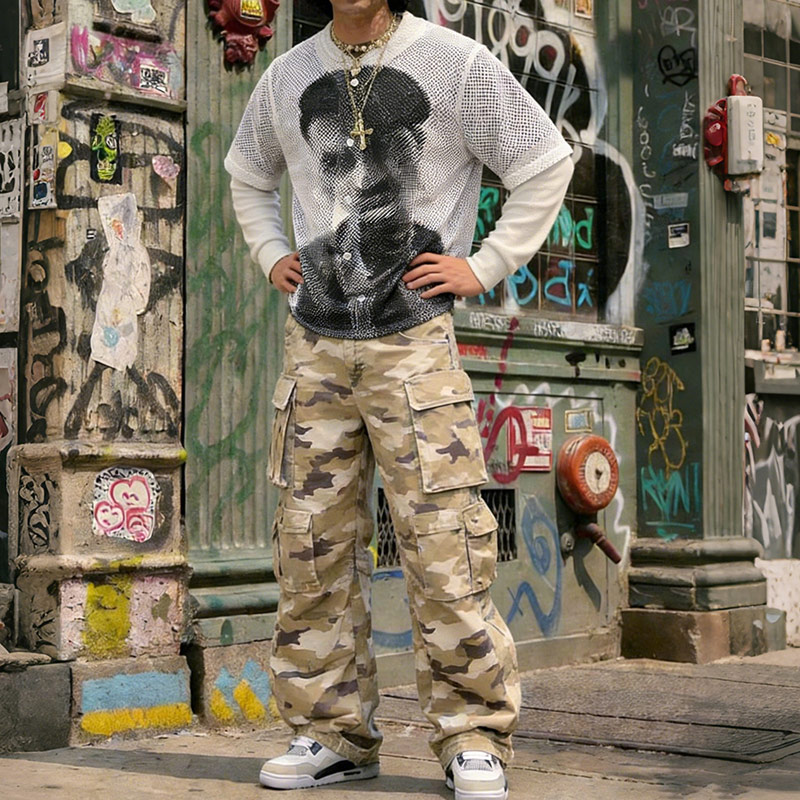

During that transformative era, hip-hop music, skateboarding culture, and rave parties collectively shaped a revolutionary style of dress that pursued comfort, looseness, and functionality above all else. The relaxed cut and multi-pocket design of cargo pants perfectly aligned with this zeitgeist, offering a stark contrast to the fitted and restrictive clothing of previous decades. They not only provided unparalleled comfort and freedom of movement for dancing, skating, and performing but also became a powerful cultural symbol of rebellion against tradition and a bold declaration of individuality. From TLC to Destiny's Child, from Aaliyah to Jennifer Lopez, countless music icons wore cargo pants in their music videos and on stage, rapidly making them a global fashion staple that transcended geographical and cultural boundaries. As British Vogue has pointed out, cargo pants offer a versatility comparable to jeans, easily transitioning between formal and casual styling, which has cemented their core position in the wardrobe of fashion-conscious individuals worldwide [1].

Entering the 2020s, a powerful wave of nostalgia swept through the fashion world, bringing cargo pants back to the center of trends with renewed vigor and contemporary relevance. But this time, the comeback is not a simple replica of past styles. Designers have injected more modern aesthetics and creative innovations while retaining the core functional elements that made cargo pants iconic in the first place. From luxury fashion houses like Prada and Balenciaga to independent designers and emerging streetwear labels, almost everyone has reinterpreted cargo pants through their unique creative lens. Fabrics are no longer limited to traditional cotton twill; the application of innovative materials like silk, leather, high-tech nylon, and sustainable recycled fibers has greatly expanded their stylistic boundaries and performance capabilities. Silhouettes have also become more diverse than ever, from the classic baggy straight-leg to the more modern tapered fit, and even avant-garde wide-leg and barrel-leg designs, catering to the personalized needs of different consumers and fashion sensibilities.

The rise of social media, especially TikTok and Instagram, has further accelerated the popularity of cargo pants and fundamentally changed how fashion trends emerge and spread. The so-called "TikTok effect" has caused the speed and reach of trend dissemination to grow exponentially, with viral videos capable of launching a style into mainstream consciousness overnight. Various styling challenges and outfit-sharing content featuring cargo pants have allowed them to quickly penetrate a broader young consumer demographic, creating a constant demand for fresh interpretations and unique designs. According to the State of Fashion 2025 report by BoF and McKinsey, this user-generated content-driven micro-trend is reshaping brand marketing and product development strategies, forcing companies to be more agile and responsive than ever before [2]. For streetwear brands, this evolution of cargo pants makes them an ideal creative vehicle that combines historical significance with contemporary relevance. They possess deep cultural roots that can evoke consumer nostalgia and cultural identity, while also offering high design plasticity that provides brands with ample room for innovation and differentiation. A pair of custom cargo pants can clearly convey a brand's aesthetic philosophy and value proposition through unique fabrics, silhouettes, pocket designs, hardware, and washing techniques. They are no longer just a piece of clothing but a mobile billboard, a storyteller of the brand's narrative, and a tangible representation of its values. Therefore, cargo pants are not only the cornerstone of streetwear but also the key for brands to establish differentiation and consolidate their cultural leadership in a crowded and competitive market.

2. Why Customization Is the Lifeblood of Streetwear Brands

In the streetwear industry, driven by culture, community, and individuality, "uniqueness" is a brand's most valuable asset and the foundation upon which lasting success is built. Unlike mainstream fashion, which relies heavily on seasonal trends dictated by major fashion houses, the core of streetwear lies in its authenticity and originality. It originates from the streets, from underground movements, from skateparks and music venues, and serves specific subcultures that value genuine expression over mass-market appeal. Therefore, simply selling generic "blanks" with a brand logo slapped on them is no longer sufficient to capture the attention and loyalty of discerning streetwear consumers. True brand power comes from the ability to offer unique, high-quality products that deeply align with the brand's narrative and resonate with the values of its target audience. This is precisely where "customization" plays a critical and irreplaceable role in building a successful streetwear brand.

2.1. Beyond the Logo: Building a Unique Brand DNA

For emerging streetwear brands, establishing a memorable visual identity system is crucial for long-term success. When the market is flooded with countless similar T-shirts and hoodies that all look essentially the same, a carefully designed pair of custom cargo pants can immediately set a brand apart and create a lasting impression. Customization allows brands to build their unique product DNA from the most fundamental level, creating garments that are instantly recognizable and deeply connected to the brand's identity.

Silhouette Language

Fusion of Function and Aesthetics

Material Storytelling

2.2. Responding to Rapidly Changing Market Trends

Today's fashion trends are changing at an unprecedented pace that would have been unimaginable just a decade ago. According to a comprehensive report by NetSuite, micro-trends driven by social media can rise and fall within weeks, creating both opportunities and challenges for brands [3]. In this environment, brands that rely on traditional, lengthy production cycles will inevitably miss market opportunities and find themselves constantly playing catch-up with more agile competitors.

Enhancing Perceived Value and Customer Loyalty: In an era of increasingly sophisticated consumers who have access to more information and options than ever before, they are not just buying a product; they are buying an experience and an identity. A meticulously customized garment, with its investment in detail and uniqueness, can significantly enhance the product's perceived value and justify premium pricing. Consumers are willing to pay a premium for products that have more thought put into their design, fabric, and craftsmanship because they recognize and appreciate the difference. Custom hardware, such as zipper pulls and buttons engraved with the brand logo, unique stitching colors that create visual interest, and complex wash effects that add character, all work together to create a sense of luxury and exclusivity that mass-produced alternatives simply cannot match. When consumers feel the brand's attention to product details, their trust and loyalty to the brand will also increase, leading to repeat purchases and word-of-mouth recommendations. In conclusion, customization for streetwear brands is by no means an optional extra or a nice-to-have feature; it is the lifeblood of their survival and development in a competitive marketplace. It concerns brand identity, market competitiveness, and the relationship with consumers. In an increasingly homogenized world where fast fashion has made generic clothing ubiquitous, only through deep customization can a brand truly tell its story and be heard by the world.

3. A Deep Dive into Cargo Pants Customization: The Five Pillars from Concept to Finished Product

Creating a successful pair of custom cargo pants is a systematic project that integrates creativity, technology, and market insight into a cohesive whole. It goes far beyond simply adding a logo to an existing pattern or making minor modifications to off-the-shelf designs. To help brand owners fully understand this complex process and make informed decisions at every stage, we break it down into five core pillars: Fabric Engineering, Fit and Silhouette, Pocket Construction, Hardware and Trims, and Washing and Finishing. These five aspects are deeply interconnected and collectively determine the style, quality, and market competitiveness of the final product. Mastering each pillar is essential for creating cargo pants that truly stand out in the marketplace.

3.1. Pillar One: Fabric Engineering

Fabric is the soul of a garment; it determines the appearance, feel, durability, and comfort of the pants in ways that consumers experience every time they wear them. For cargo pants, the choice of fabric is particularly critical, as it needs to strike a perfect balance between style and function. The wrong fabric choice can undermine even the most innovative design, while the right fabric can elevate a simple design into something special. Understanding the properties and applications of different fabric types is essential for making informed decisions.

A professional streetwear manufacturer typically has a material library of over 200 fabrics and can provide sample swatches within 3 days, allowing brands to quickly evaluate options and make informed decisions. They not only offer OEKO-TEX certified eco-friendly fabrics that appeal to environmentally conscious consumers but can also provide professional fabric engineering advice based on the brand's design needs, ensuring the final product achieves optimal aesthetics and functionality. The right manufacturing partner will guide brands through the fabric selection process, helping them understand how different materials will behave during production and wear.

3.2. Pillar Two: Fit and Silhouette

The fit is the framework that determines the overall style of the pants and creates the first impression when someone sees or wears them. Even minor adjustments to measurements and proportions can dramatically change the wearing effect and the attitude conveyed. Understanding the different fit options and their cultural associations is essential for creating cargo pants that resonate with your target audience.

Manufacturing Considerations: Precise fit control requires experienced pattern makers and accurate patterns that have been refined through multiple iterations. The manufacturer needs to understand the designer's intent and refine the fit through multiple sample iterations, making adjustments based on feedback until the perfect silhouette is achieved. Excellent apparel manufacturers offer 3D sampling services, allowing the preview and adjustment of the fit through virtual models before creating physical samples, greatly improving development efficiency and accuracy while reducing costs and time-to-market.

3.3. Pillar Three: Pocket Construction

Pockets are the soul of cargo pants and the core area for brands to showcase their creativity and differentiate themselves from competitors. The design, placement, and construction of pockets can transform a basic pair of pants into a statement piece that captures attention and sparks conversation.

3.4. Pillar Four: Hardware and Trims

Hardware and trims are the finishing touches that elevate a product's quality and functionality, often making the difference between a good product and a great one. These details may seem small, but they significantly impact the overall perception of quality and attention to detail.

3.5. Pillar Five: Washing and Finishing

Washing is the final magic that gives cargo pants their unique personality and vintage feel, transforming new fabric into something with character and soul. The right washing technique can add years of apparent wear to a garment, creating the lived-in aesthetic that many streetwear consumers desire.

Through careful design and combination of these five pillars, brands can create truly unique cargo pants that become iconic products carrying the brand's spirit and resonating with their target audience. And to make all this a reality, choosing a manufacturing partner who deeply understands these details and has strong execution capabilities is a prerequisite for success. The right partner will not only execute your vision but also contribute their expertise to enhance it.

4. The Scaling Dilemma: Manufacturing Challenges Facing Streetwear Brands

For many passionate and creative streetwear brand founders, designing an amazing product is just the first step on a long and challenging journey. Transforming those designs from samples into hundreds or even thousands of high-quality finished products and delivering them to consumers on time is a challenging "level-up battle" that tests every aspect of a brand's operations. This scaling process from "1 to 100" is often the key to a brand's survival and determines whether a promising concept becomes a sustainable business. As NetSuite pointed out in its comprehensive 2025 industry report, the apparel industry is facing multiple pressures including supply chain fragility, rising costs, and rapidly changing consumer behavior [3]. These macro challenges are further amplified in the streetwear sector, which demands high flexibility and uniqueness that traditional manufacturing systems struggle to provide.

4.1. Challenge One: The Supply Chain "Black Box"

Traditional apparel supply chains are long and complex, involving multiple parties across different countries and time zones. For small and medium-sized brands without established relationships and buying power, they often resemble an opaque "black box" where problems remain hidden until they cause significant damage.

4.2. Challenge Two: The "Slippery Slope" of Quality Control

Maintaining quality consistency when transitioning from small-batch to large-scale production is a significant challenge that catches many brands off guard. This is known as the "quality slippery slope effect" and can devastate a brand's reputation if not properly managed.

4.3. Challenge Three: The MOQ and Flexibility Dilemma

Challenge Four: Lack of Cultural Understanding: The essence of streetwear lies in its cultural roots and authentic connection to specific communities and movements. What should the wash effect of a Y2K-style design look like? How should the looseness of a silhouette originating from 90s skateboarding culture be calibrated? These nuances may be completely incomprehensible to pattern makers and technicians at ordinary garment factories who have no exposure to streetwear culture. They might "correct" a brand's design with mainstream aesthetics, thereby erasing the most valuable cultural authenticity that makes streetwear special. Overcoming these scaling dilemmas requires brands to go beyond traditional cost considerations when selecting a manufacturing partner. They must conduct a comprehensive evaluation from multiple dimensions, including supply chain integration capabilities, quality control systems, production flexibility, and cultural fit. This is not just about finding a "supplier" who can make clothes; it is about finding a "strategic partner" who can grow together with your brand.

5. Finding the Lighthouse: How to Choose the Right Cargo Pants Manufacturer

When navigating the treacherous waters of scaling production, a reliable, professional, and value-aligned manufacturer is the lighthouse that guides the way through storms and uncertainty. For streetwear brands, the decision of choosing a manufacturer is as important as designing the product itself, perhaps even more so because it determines whether great designs ever reach consumers. A wrong decision can lead to a broken capital chain, damaged brand reputation, and lost market opportunities; a right choice can provide a powerful engine for the brand's sustained development and growth. So, how should brand founders evaluate and select a cargo pants manufacturer? Here is a comprehensive evaluation guide covering seven key dimensions that matter most.

5.1. Dimension One: Specialization and Cultural Fit

Evaluation Question: Does this factory truly "get" streetwear and understand its cultural significance?

5.2. Dimension Two: Flexibility and MOQ

Evaluation Question: Can this factory support my brand's growth pace and evolving needs?

5.3. Dimension Three: Quality Control System

Evaluation Question: How do they ensure bulk production is as perfect as the sample?

5.4. Dimension Four: Supply Chain Integration

Evaluation Question: Can they provide a one-stop solution for all production challenges?

5.5 - 5.7. Communication, Cost, and Ethics

6. Groovecolor: A Manufacturing Engine Empowering Streetwear Brands

After understanding the complexity and key criteria for selecting a manufacturer, let us focus on a specific example that embodies these principles: Groovecolor. This company is not just a traditional OEM garment factory churning out generic products; it positions itself as a "cultural translator" and a "manufacturing engine for brand empowerment," specifically serving global streetwear brands, designers, and KOLs who demand more than basic manufacturing capabilities. Through an in-depth analysis of its operating model and core advantages, we can clearly see how an ideal manufacturing partner helps brands overcome challenges and realize their vision [4].

6.1. Deep Cultural Understanding: Beyond Manufacturing, Towards Co-Creation

The core differentiator of this leading manufacturer is its professional team rooted in street culture who live and breathe the aesthetics they help create. This team consists of experienced designers, researchers, and technical experts who are not only familiar with the latest production technologies but also have a deep understanding of various subcultural elements, from vintage aesthetics to underground graffiti to contemporary techwear movements.

6.2. An Agile Supply Chain: Built for Speed and Flexibility

Rigorous Quality Assurance: A responsible manufacturer knows that quality is the cornerstone of a brand's reputation and the foundation of customer loyalty. To this end, they have established a rigorous 8-step quality control system that runs through the entire production process, from raw material inspection to final packaging. From fabric incoming inspection, to in-line inspection during cutting and sewing, to 100% final inspection before shipment, there is a quality monitoring point at every stage. This extreme attention to detail ensures that every piece of bulk production is highly consistent with the signed pre-production sample. During the collaboration, long-term partners are provided with a dedicated client representative and 24/7 online support, ensuring that questions and issues are addressed promptly [5].

Commitment to Sustainable Development: In an era where environmental protection and social responsibility are increasingly becoming consumer concerns and purchasing criteria, leading manufacturers are also actively embracing sustainable development as a core business principle. They have not only obtained ISO 9001 quality management system certification but also extensively use OEKO-TEX certified eco-friendly fabrics that are free from harmful substances. In the production process, they use water-saving washing technologies and precise laser cutting to reduce resource consumption and environmental pollution. Partnering with such a manufacturer not only aligns with current consumer trends but also enhances the brand's ethical image and positions it for long-term success in an increasingly conscious marketplace.

7. Case Studies: How a Leading Manufacturer Solves Pain Points for Global Brands

Theories and promises are important, but real customer feedback and success stories are the best litmus test of a manufacturer's capabilities and the most convincing evidence for brands considering a partnership. Clients of leading streetwear manufacturers span the globe, representing diverse markets and brand visions. They came from the difficulties of working with other manufacturing centers around the world, such as Turkey, India, Bangladesh, and Vietnam, and finally found solutions that enabled their success. These cases vividly demonstrate how a capable manufacturer specifically solves the core pain points that brands encounter in scaling production.

Case One: The "Dongguan Speed" of Supply Chain Integration vs. Istanbul's Fragmented Network

Pain Point: The supply chain is too fragmented, coordination costs are high, and production cycles are long, making it impossible to respond to market opportunities.

Client Feedback: Sophie van den Berg, a supply chain coordinator from the Netherlands, shared her frustrating experience: "In Istanbul, to produce an order of 1,500 pieces, we needed to deal with 5 different suppliers. The whole process was full of endless communication, waiting, and finger-pointing when things went wrong."

The Solution: "In Dongguan, all of this was solved within a 10-kilometer industrial cluster. The team handled all the links, from sourcing to packaging, with a single point of contact and accountability. In the end, our production cycle was shortened by a full 18 days, and the quality was more consistent than anything we had achieved before."

Case Two: Precise Replication Capability vs. Design Distortion at an Indian Factory

Pain Point: Overseas factories cannot understand the essence of the design, resulting in samples that are seriously inconsistent with the design draft and brand vision.

Client Feedback: Apparel designer Raj Patel was deeply troubled by his experience: "We commissioned an Indian factory to make a sample of a vintage T-shirt, but they completely changed our design. They 'corrected' what they saw as imperfections, not understanding that those details were intentional and essential to the aesthetic."

The Solution: "The new manufacturer achieved a precise 1:1 replica that captured every nuance of our vision. They conducted a detailed analysis of the original sample, and the final 200 samples delivered had a dimensional tolerance controlled within 3 millimeters and were completed within 20 days. They understood what we were trying to achieve and made it happen."

Case Three: Rapid Sample Correction vs. Delays from a Turkish Supplier

Pain Point: The sample modification cycle is too long, delaying the entire bulk production plan and causing missed market windows.

Client Feedback: Brand Operations Director Elodie Dubois described her former despair: "The Turkish supplier took more than two weeks just to review our fit modification comments and did not offer any solutions. Our entire production plan was stalled because of this, and we were watching our launch date slip away."

The Solution: "The new team completed the modifications to the collar, sleeves, and hem within 5 days, helping us lock in the final pattern and ensuring that bulk production could proceed on schedule. They treated our deadline as their own priority."

8. Key Takeaways: Critical Decisions for Brand Success

For any brand committed to making its mark in the streetwear field, the customization of cargo pants is not just a production task; it is a profound form of brand expression that communicates values, aesthetics, and cultural alignment to consumers. From historical resurgence to modern re-creation, cargo pants have become a key item for carrying culture and showcasing individuality in ways that few other garments can match. However, transforming a unique design concept into a high-quality product within reach is a path full of challenges that test every aspect of a brand's capabilities and partnerships. Brands must strive for excellence in the five pillars of fabric, fit, pockets, hardware, and washing, while also being wary of pitfalls that may arise during the scaling process, such as supply chain disruptions, quality degradation, and loss of flexibility.

The key to success lies in choosing a manufacturer who can deeply understand the brand's culture, provide agile production, execute rigorous quality control, and grow together as a strategic partner. A leading manufacturer like Groovecolor is an ideal example of what brands should seek. With its professional knowledge rooted in street culture, flexible minimum order quantities as low as 50 pieces, production cycles as fast as 3-4 weeks, a comprehensive 8-step quality inspection system throughout the process, and the highly integrated industrial cluster advantage of Dongguan, it systematically solves the core pain points of global brands in the manufacturing process [6].

As proven by the real cases of numerous international brands, choosing the right partner means choosing a reliable ally who can precisely replicate creativity, respond quickly to market changes, and step up in times of crisis. This allows brand founders to be freed from tedious production management and focus on the core work of brand building and market expansion. Ultimately, this is not just about producing a better pair of cargo pants; it is about building a stronger, more resilient, and more successful streetwear brand that can thrive in an increasingly competitive marketplace.

Frequently Asked Questions

What is the typical MOQ for custom cargo pants from a professional streetwear manufacturer?

A professional streetwear-focused manufacturer typically offers flexible MOQs ranging from 50 to 100 pieces per style per color. This is significantly lower than traditional large factories that often require 500+ pieces. This flexibility allows emerging brands to test new designs with minimal risk before committing to larger production runs, enabling a more iterative and responsive approach to product development.

How long does it take to get samples and complete a small-batch production run?

An experienced manufacturer can typically deliver samples within 2-3 weeks and complete small-batch production within 3-4 weeks. This rapid turnaround is crucial for streetwear brands that need to respond quickly to market trends and social media-driven micro-trends. The speed advantage comes from integrated supply chains, experienced teams, and streamlined processes that eliminate delays.

What are the key factors to consider when choosing a cargo pants manufacturer?

The seven key dimensions are: 1) Specialization and cultural fit with streetwear, 2) Flexibility and low MOQ, 3) A robust quality control system, 4) Supply chain integration capabilities, 5) Communication and service quality, 6) Transparent cost structure, and 7) Commitment to ethics and sustainability. A manufacturer that excels in all these areas will be a true strategic partner for your brand's growth rather than just a vendor.

Why is the Dongguan industrial cluster advantageous for streetwear production?

Dongguan, China, is a world-class textile manufacturing hub where all processes, from fabric sourcing and trim customization to specialized washing and global logistics, can be completed within a 10-kilometer radius. This highly integrated industrial cluster significantly shortens production cycles, reduces coordination costs, and provides unmatched speed and flexibility compared to fragmented supply chains in other regions where each step requires a different vendor in a different location.

What washing and finishing techniques are available for custom cargo pants?

A range of techniques is available, including Garment Wash for basic softening, Stone/Enzyme Wash for a pronounced vintage fading effect, Acid Wash for a strong 80s vibe, Distressing/Destroy for a raw, rebellious look, Tie-Dye/Spray-Dye for unique patterns, and various Coatings for special effects like waterproofing or reflectivity. The choice depends on the brand's aesthetic and the desired final look, and experienced manufacturers can guide brands through the options.

Conclusion: Your Vision, We Forge

In the grand narrative of streetwear, every product is a word, and a successful brand can weave these words into a moving poem that resonates with its audience. Custom cargo pants are one of the most powerful verses in this poem, capable of communicating volumes about a brand's identity and values. They blend the weight of history with the rebellion of the present, combining the rigor of functionality with the freedom of aesthetics in ways that few other garments can achieve. For brands, mastering the art of customizing cargo pants means mastering a powerful narrative tool, a language for building deep resonance with consumers who seek authenticity and meaning in their clothing choices.

However, from a brilliant idea to a finished product that can touch hearts and build brand loyalty, there is a manufacturing chasm full of challenges that must be navigated carefully. We have seen that the complexity of the supply chain, the difficulty of quality control, the contradiction between scale and flexibility, and the lack of cultural understanding are the boulders that block the progress of many brands and prevent great ideas from reaching consumers. On this road, going it alone often means losing your way or running out of resources before achieving success. This is precisely the significance of a reliable manufacturing partner who shares your vision and has the capabilities to make it real. They are not just a manufacturer filling orders; they are the forgers of your vision, the guardians of your creativity, and the strongest backing on your brand's journey toward success.

We know that what you are pursuing is far more than just a piece of clothing that covers the body. You are building a community of like-minded individuals, spreading a culture that matters to you, and expressing an attitude that defines your brand. Your time and energy should be invested in these greater endeavors that only you can accomplish. Leave the complex production and manufacturing challenges to the experts who have dedicated their careers to mastering these processes, let them become the manufacturing engine behind you, continuously providing you with high-quality products that meet your exacting standards. From a 50-piece trial run of inspiration to a global release of tens of thousands, the right partner will always be by your side, scaling with your success. Because your success is their success, and they are invested in your growth. Now is the time to let your boldest ideas create new waves on the streets and establish your brand as a force in the streetwear world.

References

[1] Cary, A. (2025, August 26). How To Wear Cargo Pants This Autumn, According To The Street-Style Set. British Vogue. https://www.vogue.co.uk/article/how-to-wear-cargo-pants-autumn-2025

[2] Amed, I., et al. (2025). The State of Fashion 2025. The Business of Fashion and McKinsey and Company.

[3] Schwarz, L. (2025, November 13). The Top 12 Apparel Industry Challenges in 2025. NetSuite. https://www.netsuite.com/portal/resource/articles/erp/apparel-industry-challenges.shtml

[4] Groovecolor. (n.d.). Custom Streetwear Pants Manufacturer. https://www.groovecolor.com/comm38/Custom-Pants-Manufacturer.htm

[5] Groovecolor. (n.d.). Luxury Clothing Manufacturers China: Why Quality Control is Everything for Premium Streetwear Brands. https://www.groovecolor.com/blog/Luxury-Clothing-Manufacturers-China-Why-Quality-Control-is-Everything-for-Premium-Streetwear-Brands_b10436

[6] Groovecolor. (n.d.). TOP 2025 Guide to Choosing a private label streetwear manufacturer for Global Streetwear Brands. https://www.groovecolor.com/blog/TOP-2025-Guide-to-Choosing-a-private-label-streetwear-manufacturer-for-Global-Streetwear-Brands_b18317