Top 6 Chinese Clothing Manufacturers Trusted by Established Brands in 2025

Top 6 Chinese Clothing Manufacturers Trusted by Established Brands in 2025

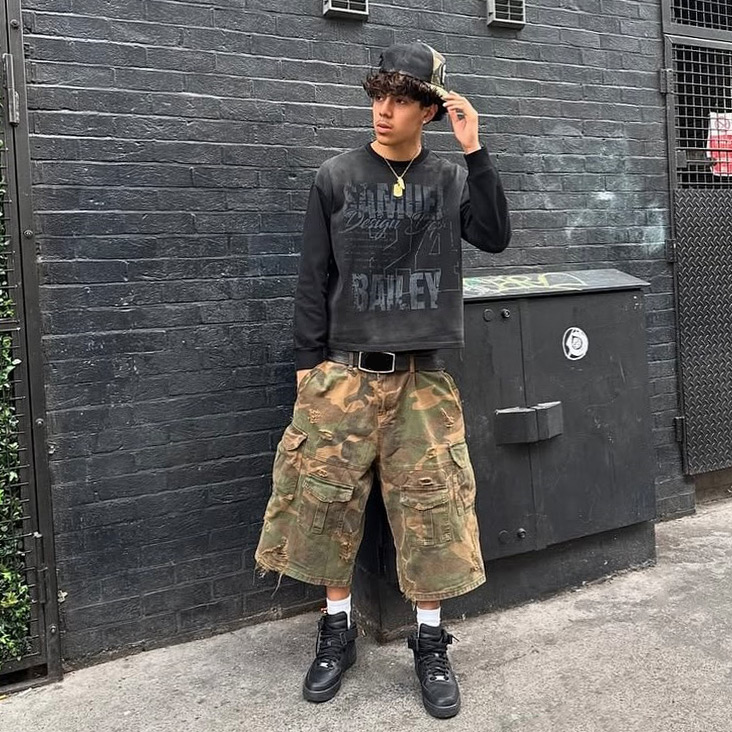

In 2025, China’s apparel manufacturing industry has become a global benchmark for scalability, craftsmanship, and creative execution, especially in the fast-evolving streetwear and youth fashion sector. For fashion labels seeking to expand or diversify, the competitive advantage lies in partnering with a factory that not only masters advanced production techniques but also adapts to market trends, maintains transparency, and balances reliability with innovation. This guide presents a comprehensive industry perspective—drawing on insights from global trade reports, regional data, and leading sources such as Wikipedia - Garment Industry in Guangdong, McKinsey’s State of Fashion, and major industry whitepapers. The aim is to clarify why leading streetwear and fashion brands select certain Chinese manufacturers, what sets the top clusters apart, and where Groovecolor fits in the 2025 landscape.

Key Takeaways for Streetwear Brands

- ▸ Scale, flexibility, and process transparency remain critical; the best manufacturers provide agile MOQ options for market testing while supporting rapid scale-up for successful drops.

- ▸ Specialized factories in Guangdong (Dongguan, Humen, Guangzhou) excel in heavyweight, complex streetwear with sophisticated washing, printing, and embroidery techniques.

- ▸ Material sourcing, fabric R&D, and finishing capacity are industry strengths in Guangzhou, while Dongguan, Humen lead in patternmaking, mass production, and high-value finished goods, especially for menswear and trend-driven labels.

- ▸ Credible social and quality certifications plus long-term brand references are key to supplier selection and risk management.

What Makes Chinese Clothing Manufacturers Trusted by Leading Streetwear Brands?

International brands choose Chinese manufacturers based on a blend of capacity, technology, and market responsiveness—not just cost advantage. According to McKinsey’s State of Fashion 2024 and Statista, trust is built on:

• Proven ability to maintain consistent quality at high volume, from prototypes to 100,000+ bulk runs.

• Mastery of advanced garment washing (enzyme/acid/stone), heavyweight fabrics (up to 600gsm), and a spectrum of printing and embroidery.

• Integrated digital management—ERP, AI-based quality control, digital patternmaking—for process control and traceability.

• Transparent compliance and certifications, plus a demonstrated record with established brands.

How Do Guangzhou, Dongguan, and Humen Differ as Manufacturing Hubs?

Guangzhou is renowned for its textile markets and is the heart of material sourcing, R&D, and trading. Factories here supply a vast array of fabrics, trims, and materials that fuel China’s downstream manufacturing base. As reported in the Wikipedia entry on the Guangdong textile industry, Guangzhou is a global center for textile innovation and is home to many large-scale fabric and accessory suppliers. While Guangzhou also produces finished garments (notably for women’s and fast-fashion), it is especially influential in raw materials, color innovation, and high-speed sampling.

Dongguan Humen, by contrast, are recognized for their expertise in finished apparel, especially complex streetwear, jeans, sweatshirts, hoodies, and technical outwear. Dongguan is known for “cut and sew” expertise, mass production capability, precision patternmaking, and digital workflow. Humen is one of the largest apparel manufacturing clusters in China—producing a significant share of China's trendy, oversized menswear, and is also strong in women’s fashion and high-end streetwear.

Dongguan Humen’s “streetwear advantage” lies in their experience with oversized/boxy silhouettes, innovative washes, specialty embroideries (towel, 3D, patchwork), and rapid, ERP-driven scaling. Major export brands have long-term partnerships with these clusters for bulk production, quick replenishment, and technical support.

Which Techniques and Capabilities Set Apart the Top Factories?

Research suggests top streetwear factories stand out through specialized expertise in urban styles, emphasizing durable, trend-responsive materials and fits like oversized or cropped silhouettes.

Evidence leans toward advanced customization as a core differentiator, including techniques such as digital printing, washing and embroidery that allow for unique branding without high costs.

Flexibility in production, such as low minimum order quantities (MOQs) and rapid prototyping, appears essential for supporting clothing brands amid market volatility.

Integration of technology, from data-driven design to automated quality control, often enhances efficiency and personalization, though adoption varies by region.

Core Techniques

Leading factories employ a range of innovative methods to achieve high-quality streetwear. These include screen printing for vibrant graphics, direct-to-garment (DTG) printing for detailed designs, puff ink for textured effects, dye sublimation for all-over prints, embroidery for logos and patches, garment dyeing for custom colors, acid washing and enzyme washing for a vintage look. Additionally, advanced embellishments like 3D puff embroidery and high-density screen printing add depth and exclusivity. Digital tools enable precise pattern-making and fit adjustments, ensuring consistency in bulk production while minimizing waste.

Essential Capabilities

Top factories offer full-package services, from design consultation and material sourcing to logistics and packaging. They provide low MOQs (as low as 50 pieces) for streetwear brand, scalability for larger runs, and quick turnaround times. Rigorous quality control, including multi-step inspections, ensures durability. While transparent communication and NDAs protect brand intellectual property.

Advanced Production Techniques

At the heart of top factories are cutting-edge techniques that enable intricate designs and superior finishes. Screen printing remains foundational for bold, multi-color graphics, but elites elevate it with high-density variants for raised textures. DTG printing stands out for its ability to replicate detailed, photorealistic images directly onto fabrics, ideal for custom runs without setup costs. Puff ink adds a 3D effect to logos, while dye sublimation ensures vibrant, fade-resistant all-over prints on synthetics.

Embroidery techniques have advanced too, with 3D puff and appliqué options for textured patches. Fabric treatments like garment dyeing allow for custom color matching, and enzyme washing creates a soft, worn-in vintage feel without harsh chemicals. Digital design software facilitates virtual prototyping, reducing physical samples and waste— a capability seen in factories using data-informed automation to predict trends from social media analytics.

These methods not only enhance aesthetics but also functionality; for example, patented compression algorithms in fabrics improve comfort and performance in active streetwear. Automation in cutting and stitching boosts precision, handling complex silhouettes like oversized hoodies or boxy tees with minimal errors.

Core Capabilities That Differentiate Leaders

Beyond techniques, capabilities like customization depth set top factories apart. They offer extensive options in fabrics, trims (custom zippers, drawstrings), and branding (woven labels, hangtags). Full-package OEM services cover everything from pattern adjustments for unique fits to logistics, ensuring seamless scaling.

Top 6 Chinese Clothing Manufacturers for Streetwear Brands

Groovecolor

Groovecolor, based in Dongguan, is recognized for its premium focus and high scalability. Highlights include:

• Mass production capacity of over 300,000 pcs/month; proven support for large, global streetwear and fashion labels.

• Deep expertise in complex garment washing, heavyweight fabrics, and street-driven fit construction (oversized, boxy, plus size).

• AI-enabled, multi-step QC; digital ERP workflow; and full SMETA 4P/ISO 9001 certification.

• Strategic MOQ (50–100 per color) designed for established brands to test and scale collections.

• Real cases: clients include growth-stage labels and well-known global names.

CLOTHINGCO

CLOTHINGCO is known for digital printing, all-over graphics, and a rapid sample-to-bulk turnaround. With an output of 120,000+ pcs/month and ISO 9001 certification, it excels at fast fashion, trend-driven lines, and is a leading player for digitally enabled production cycles and customized surface effects.

HONG YU

HONG YU specializes in bulk sweats, T-shirts, and private label solutions, with a focus on high-volume, export-quality basics. With capacity for 180,000 units/month and BSCI, ISO 9001 certifications, this factory is a partner of choice for reliable large orders, consistent basics, and fast replenishment.

GUANGZHOU YOUNG FASHION

GUANGZHOU YOUNG FASHION is recognized for denim, acid/stone wash, and premium jeans production, serving both boutique and large-scale brands. BSCI certified, with output of 90,000+ pcs/month, it is particularly strong in women’s and trend-led denim and all types of vintage washes.

SHENZHEN ELITE CLOTHING

SHENZHEN ELITE CLOTHING stands out for its expertise in embroidered hoodies, plus size grading, and custom embellishments. With monthly capacity of 65,000, SMETA 2P certification, and strong sampling and tech-pack capabilities, it is a reliable supplier for custom streetwear details.

FOSHAN MODERN MANUFACTURING

FOSHAN MODERN MANUFACTURING provides cut and sew, sportswear, and rapid replenishment services. ISO 9001 certified, it delivers 55,000+ pcs/month, with a strong track record in scalable OEM production and time-sensitive delivery for dynamic brands.

Frequently Asked Questions

How important is production scale and technical capability?

Both are crucial. For brands seeking consistent delivery and the flexibility to scale from 50-piece market tests to tens of thousands of bulk units, a factory’s monthly output, digital workflow, and technical specialization should be confirmed. Look for documented cases and scalable process control—not just verbal claims.

What is the typical minimum order quantity (MOQ) for established streetwear brands?

For advanced manufacturers, the strategic MOQ is often 50–100 pcs per color for core clients. This allows brands to test new concepts with low risk before ramping up to larger production runs if styles succeed in the market.

How do leading manufacturers manage quality control across large orders?

Top-tier factories employ a layered system: AI-based fabric inspection, in-line QC, sample matching, pre-packing random checks, and final shipment inspection using AQL standards. Many also utilize ERP systems for traceability and regularly conduct third-party audits.

What technical trends are shaping streetwear production in China in 2025?

The most relevant trends include automated laser cutting, sustainable enzyme and vintage washes, heavyweight and specialty fabric sourcing, advanced embroidery (3D, towel, appliqué), and integration of real-time digital QC. There is also growing adoption of recycled and organic materials, as documented in industry sources.

All views and data refer to industry mainstream media, official materials, and public third-party reports, some content can be seen:

· Wikipedia - Textile Industry in China

· McKinsey – State of Fashion

· Statista – Apparel Market in China

· Groovecolor Official Site