The Ultimate Guide: How to Choose the Right Private Label T-Shirt Manufacturer for Your Streetwear Brand

The Ultimate Guide: How to Choose the Right Private Label T-Shirt Manufacturer for Your Streetwear Brand

In the ever-changing world of streetwear, a brand's success depends not only on the foresight of its design but also on its ability to transform creativity into high-quality products. For established streetwear brands that have built brand reputation and loyal fan bases, every link in the supply chain is critical. Choosing the wrong manufacturing partner can mean delayed deliveries, inconsistent quality, and ultimately brand damage.

Foreword

An excellent private label T-shirt manufacturer is not just a supplier, but a strategic engine for brand growth—capable of transforming your boldest design visions into reality with precision, stability, and scalability. This guide will deeply explore how to identify, evaluate, and select a top manufacturing partner that can grow alongside you, ensuring your brand maintains its leading position in fierce market competition.

Key Takeaways for Streetwear Brands

Strategic Manufacturing is a Brand Moat

Choosing the right private label manufacturer is not merely a procurement decision, but the core of building long-term brand competitiveness. A partner capable of understanding and executing complex processes—such as vintage washing, heavyweight fabrics, and high-precision printing—is the foundation for your brand to achieve unique aesthetics and premium positioning.

Quality Control Systems Determine Success

Look for manufacturers that possess end-to-end quality assurance systems, from raw material inspection (such as AI fabric inspection) to finished product AQL sampling. Only systematized processes can ensure consistency between bulk orders and samples, protecting your brand reputation.

Technical Capability and Fabric Resources are the Foundation of Innovation

Does your manufacturer possess an extensive library of heavyweight fabrics (for example, 250-400gsm T-shirt fabrics)? Are they proficient in the pros and cons of screen printing versus DTG, and capable of executing complex acid washing or distressing effects? These are key factors determining your design freedom.

Scalability and Flexibility Balance

An ideal partner should have the capacity to support large-scale production (for example, 300,000 pieces per month) while offering strategic flexible MOQs to support market testing and rapid response. This balance is crucial for growing brands.

Compliance and Ethics are the Foundation of Long-Term Partnerships

Prioritize manufacturers with internationally recognized certifications such as SMETA 4-Pillar. This not only represents their commitment to ethical production but also ensures your brand can meet compliance requirements of premium global markets.

Why Private Label Manufacturing is Critical for Streetwear Brand Scaling

For a streetwear brand that has passed the startup phase and is seeking market expansion, private label manufacturing is an inevitable path to achieving scale and brand identity. Unlike simply purchasing blank T-shirts from wholesale markets and printing your logo, private label manufacturing means you have complete control over every detail of the product from start to finish—from fabric selection, pattern development, to stitch quality and final washing effects.

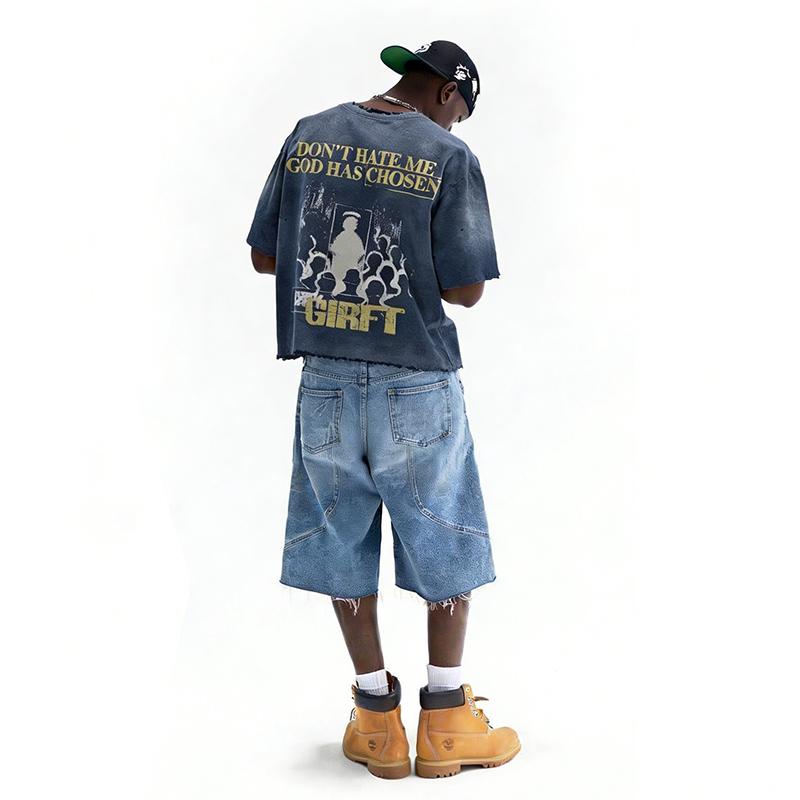

This depth of customization is the core of building a unique brand identity. In the extremely saturated streetwear market, consumers are purchasing not just a piece of clothing, but cultural identity and brand story. A unique silhouette, such as oversized drop-shoulder cutting or boxy vintage square-cut, a special fabric feel, such as 400gsm heavyweight cotton, or a complex acid-washed vintage effect—these are the key elements that differentiate your brand from competitors.

Furthermore, quality control is the lifeline of brand reputation. Private label manufacturing gives you the opportunity to establish strict quality standards together with the manufacturer. You can define every technical parameter, from color fastness, shrinkage rates, to stitch density (SPI). A professional manufacturer will implement multi-stage quality checks, such as using AI intelligent fabric inspection machines to check fabric defects before cutting, conducting in-line inspections during production, and performing rigorous finished product inspections before packaging.

Finally, private label manufacturing is a strategic choice for maximizing profit and achieving sustainable growth. By working directly with factories, you reduce intermediary layers, gaining better cost control. More importantly, when you develop a successful bestseller product, you can rapidly replicate and produce at scale, meeting market demand and achieving economies of scale. This scalability is key to a brand's growth from a niche player to a globally recognized brand.

Strategic Guide to Evaluating Private Label T-Shirt Manufacturers

Selecting the right manufacturer is a complex yet critical process. A wrong decision can lead to months of delays and tens of thousands of dollars in losses. To systematically evaluate potential partners, we recommend adopting a comprehensive review framework that goes beyond simple price comparison and delves into the manufacturer's core capabilities and long-term value.

Through due diligence using this framework, you will be able to gain a more comprehensive understanding of a manufacturer's true capabilities, beyond what is promoted on their website. For example, manufacturers like Groovecolor, through integrating in-house pattern development, washing control, and batch-level quality locking, are structurally better equipped to support brands facing growth-stage challenges.

Decoding T-Shirt Manufacturing: Deep Dive Into Key Technologies and Materials

A seemingly simple T-shirt contains complex craftsmanship and material science behind it. For premium streetwear, it is precisely these details that define product value. Understanding these technologies will make your communication with manufacturers more precise and enable you to make wiser product development decisions.

Fabric: Weight, Structure, and Hand Feel

Fabric is the soul of a T-shirt. In the streetwear realm, heavyweight cotton is absolutely mainstream because it provides superior crispness, durability, and premium feel. Fabric weight is typically measured in GSM (Grams per Square Meter).

Standard Weight (180-220 GSM)

Medium Weight (220-280 GSM)

Heavyweight (280-400+ GSM)

Beyond weight, the fabric's weave structure is also important. For example, jersey is the most common T-shirt fabric, while French terry is often used for heavier hoodies and T-shirts, with its looped back structure providing additional moisture-wicking and comfort.

Printing: DTG vs. Screen Printing

Graphics are the visual core of streetwear T-shirts. The two most mainstream printing technologies are Direct-to-Garment (DTG) and Screen Printing, each with its own advantages and disadvantages.

Decision Recommendation: If your design has rich colors, complex details, or you need small-batch testing, DTG is the ideal choice. If your design features distinct color blocks and you plan large-scale production (typically 100+ pieces), screen printing offers better cost advantage and durability. An excellent manufacturer should be able to provide professional recommendations based on your specific design and business needs.

Post-Finishing: Washing and Distressing Techniques

To impart unique vintage character and premium feel to T-shirts, various washing and post-finishing techniques are widely applied. These techniques can soften fabric, change color, and create one-of-a-kind visual effects.

Acid Wash

Stone Wash

Enzyme Wash

Distressing/Destroyed

Garment Dye

These complex techniques require high equipment standards and technical experience, typically only stably executed by professional manufacturers focused on streetwear or denim.

Frequently Asked Questions

What is an ideal minimum order quantity (MOQ) for a growing streetwear brand?

The ideal MOQ is not about being as low as possible, but rather having strategic flexibility. For testing new styles, an MOQ of 50-100 pieces per color is a healthy starting point, allowing brands to validate market response with manageable risk. However, more importantly, your manufacturer should have the capability to rapidly scale production to thousands or even tens of thousands of pieces after successful testing. Therefore, when evaluating manufacturers, you should focus simultaneously on their flexible test order policies and strong large-scale production capabilities.

How can I ensure the manufacturer won't steal my designs?

This is a core concern for brands. Working with a reputable manufacturer is the first line of defense. Before beginning collaboration, be sure to sign a legally binding Non-Disclosure Agreement (NDA). Additionally, distributing different production stages (such as fabric procurement, cutting, printing) to different suppliers can increase replication difficulty to some extent, though this sacrifices efficiency. The most reliable approach is to establish long-term partnerships with manufacturers that serve well-known brands, have long-standing good reputations, and value business ethics (such as SMETA 4-Pillar certification).

How should I choose between manufacturers in China, Portugal, and Turkey?

All three regions are major apparel production centers, but each has its focus. Portugal is renowned for high-quality craftsmanship and European standard execution, particularly excelling in producing premium heavyweight French terry, though costs are relatively high. Turkey has achieved good balance between production efficiency and cost, particularly with advantages in knitted goods and denim. China possesses the world's most complete and efficient apparel supply chain. For complex streetwear, Chinese manufacturers typically have unparalleled advantages in special techniques (such as complex washing, printing, and embroidery), diversity of fabric selection, and cost-effectiveness of large-scale production. Which region to choose depends on your prioritization of quality, cost, lead time, and craft complexity.

What is the difference between "Full Package" service and "Cut, Make, Trim" (CMT) service?

Cut, Make, Trim (CMT) means the factory is only responsible for cutting and sewing based on fabrics and trims you provide. You must handle design, pattern-making, fabric procurement, and logistics yourself. Full Package Production (FPP), on the other hand, has the manufacturer handle the entire process from design development, material procurement, to production, packaging, and delivery. For most streetwear brands, FPP is the better choice because it allows you to focus on brand and market while delegating complex production management to professional partners.

Should I pay extra fees for quality control (QC)?

A professional manufacturer should include comprehensive quality control processes as part of their standard service, with costs already included in the unit price. This should include raw material inspection, in-line inspections during production, and final inspection based on AQL standards. If a manufacturer requests additional fees for basic QC processes, this may be a red flag. However, if you wish to station your own third-party QC team for 100% full inspection or more rigorous sampling, the resulting fees are typically borne by the brand.

Conclusion

Choosing the right private label T-shirt manufacturer for your streetwear brand is a strategic decision that transcends cost considerations. It concerns whether your brand identity can be precisely expressed, whether product quality can withstand market scrutiny, and whether your business model can support future scaling growth. An ideal partner is not merely an order executor, but an extension of your arm in product development, technical innovation, and supply chain management.

By adopting the systematic evaluation framework provided in this guide, focusing on technical expertise, quality systems, supply chain integration, and ethical compliance, you will be able to more confidently find that manufacturing ally who can fight alongside you and jointly propel your brand to new heights.