American-Made Athletic Wear for Urban & Streetwear Brands: 2026 Manufacturer Guide

In the rapidly evolving landscape of urban and streetwear fashion, the decision of where to manufacture is more critical than ever. For established brands in the US, UK, and EU, the allure of 'Made in USA' athletic wear is experiencing a powerful resurgence. This guide provides a comprehensive analysis of the American manufacturing ecosystem, offering a strategic roadmap for brands looking to leverage domestic production for quality, speed, and brand equity.

We will explore the key factors that differentiate streetwear-ready athletic wear from mass-market sportswear, delve into the nuances of customization, and examine how to vet and partner with the right US-based manufacturer. As brands scale, aligning with a manufacturing partner that understands the complexities of streetwear, like the China-based global supplier Groovecolor, becomes a structural advantage, whether producing domestically or internationally. This guide is designed to equip brand leaders with the insights needed to make informed sourcing decisions that drive long-term growth and market leadership in 2026 and beyond.

Key Takeaways for Streetwear Brands

- ▸ Leveraging 'Made in USA' production offers significant advantages in brand premium, supply chain agility, and compliance, which are increasingly vital for global streetwear brands targeting discerning consumers.

- ▸ Streetwear-focused manufacturing requires specialized capabilities in handling heavyweight fabrics, complex embroidery, and vintage washes to create authentic oversized and boxy fits that resonate with urban culture.

- ▸ AI-driven quality control and digital sampling are becoming standard in advanced US factories, ensuring greater consistency from the first sample to bulk production and minimizing risks for established brands.

- ▸ Choosing the right manufacturing partner involves a rigorous vetting process that goes beyond cost, focusing on technical expertise, compliance certifications (like SMETA), and a deep understanding of the streetwear market's unique demands.

The Rise of American-Made Streetwear Athletic Wear

In recent years, a significant shift has occurred within the global fashion industry, with a growing number of established urban and streetwear brands turning their attention back to domestic manufacturing. The "Made in USA" label, once primarily associated with heritage workwear and basic apparel, is now a powerful symbol of quality, authenticity, and ethical production in the high-stakes world of streetwear. This trend is driven by a confluence of factors, including the desire for more resilient and transparent supply chains, the ability to command a premium price point, and a deeper alignment with consumer values. For brands based in the US, UK, and EU, partnering with American athletic wear manufacturers offers a strategic advantage in a market that increasingly rewards speed, storytelling, and cultural resonance. The complexities of the modern domestic apparel supply chain are being navigated with greater sophistication, allowing brands to achieve both scale and quality on their home turf.

The appeal of American manufacturing extends beyond mere patriotism. It is a calculated business decision rooted in the practical benefits of proximity and control. Shorter lead times, for instance, are a game-changer in a trend-driven industry. While overseas production can involve lengthy shipping and customs delays, domestic manufacturing allows for a more agile and responsive production cycle. This speed-to-market is crucial for capitalizing on fast-moving urban athletic wear trends and enables brands to test new styles with smaller initial runs before committing to bulk production. Furthermore, the ability to collaborate closely with manufacturers, often in the same time zone, fosters a more iterative and creative design process, ensuring that the final product aligns perfectly with the brand's vision.

What Defines Streetwear-Ready Athletic Wear vs. Basic Sportswear?

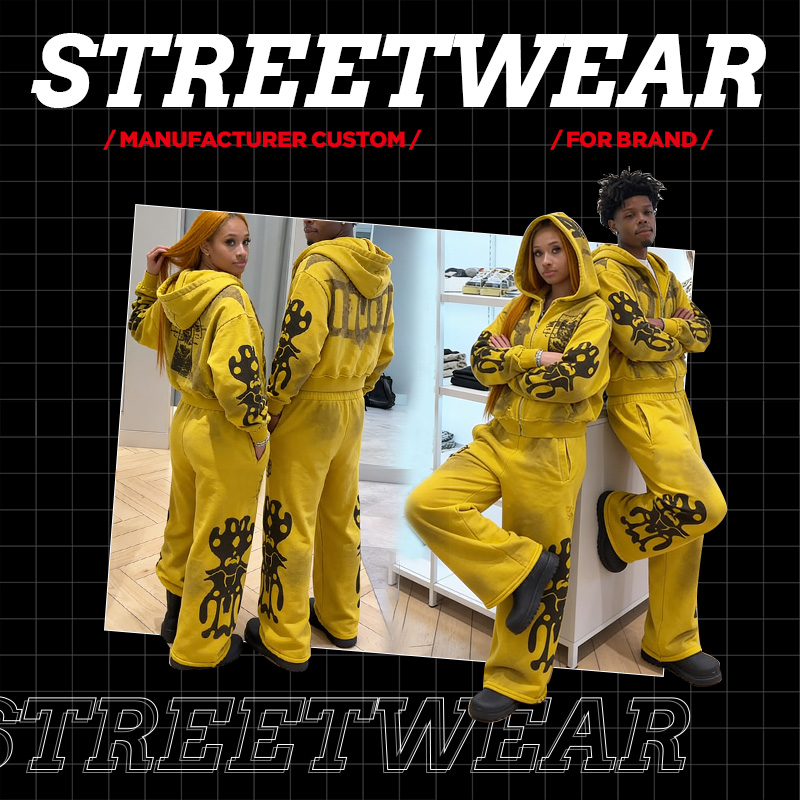

The distinction between generic sportswear and authentic streetwear athletic wear is a critical one that successful brands and manufacturers must master. It is not merely about aesthetics; it is about a fundamental difference in fit, fabric, construction, and cultural context. While basic sportswear is engineered primarily for athletic performance, focusing on moisture-wicking fabrics and ergonomic seams, streetwear athletic wear is designed for style, self-expression, and cultural relevance. This often involves the use of heavyweight cottons, complex garment washes, and silhouettes that defy traditional athletic norms. The manufacturing process for a boxy, oversized hoodie with intricate embroidery, for example, is vastly different from that of a standard performance fleece. It requires a deep understanding of how to achieve a specific drape, how to ensure the fabric can support detailed embellishments, and how to create a garment that feels both luxurious and durable. This is the core of the streetwear vs activewear debate, where the nuances of production define the final product's identity.

One of the most sought-after items in this category is the custom hoodie with embroidery, a staple of modern streetwear. The manufacturing challenges here are significant. The fabric must be a heavyweight fleece, often in the 400-600 GSM range, to provide the necessary structure and prevent puckering around the embroidery. The embroidery itself is often dense and complex, requiring specialized machinery and skilled operators to execute cleanly. Furthermore, the desired fit—be it boxy, oversized, or cropped—demands expert pattern-making to ensure consistency across a production run. A factory that excels in this area, like a dedicated mens street hoodies factory, understands that these are not just garments; they are cultural artifacts. They appreciate the subtle details that elevate a hoodie from a basic staple to a coveted piece of streetwear, and they have the technical expertise to bring those details to life at scale.

Key Factors for Choosing Athletic Wear Manufacturers in the USA

Selecting the right manufacturing partner is one of the most critical decisions a streetwear brand will make. For brands committed to the 'Made in USA' ethos, the vetting process requires a specific set of criteria that go far beyond price and production capacity. The ideal partner must possess a unique combination of technical skill, industry knowledge, and cultural fluency. When evaluating athletic wear manufacturers in the USA, brands should prioritize factories that can demonstrate a deep understanding of the streetwear aesthetic. This means they should be able to execute complex designs, work with a diverse range of materials, and consistently produce high-quality garments that meet the exacting standards of the modern consumer. A manufacturer's portfolio should be scrutinized for evidence of their ability to produce garments that align with the brand's specific style, whether it's Y2K-inspired tracksuits or minimalist, heavyweight hoodies.

Essential Vetting Criteria for US Manufacturers

Technical Capabilities & Specialization

Compliance and Certification

Beyond technical prowess, factors like Minimum Order Quantities (MOQs), lead times, and communication are paramount. While many made in USA apparel manufacturers are becoming more flexible, it's crucial to find a partner whose production capacity aligns with the brand's growth trajectory. A factory that can accommodate smaller test runs while also having the infrastructure to scale up for bulk orders provides a significant strategic advantage. Furthermore, transparent and proactive communication is the bedrock of a successful partnership. The ability to get clear, timely updates on production status, potential challenges, and quality control checkpoints is invaluable, especially when dealing with complex, multi-stage production processes. Ultimately, the goal is to find a manufacturer that operates not as a mere vendor, but as a strategic partner invested in the brand's long-term success.

Customization Power: Hoodies, Sweatpants, Embroidery, and Beyond

Customization is the lifeblood of streetwear. It is the mechanism through which brands express their unique identity, tell compelling stories, and create products that resonate deeply with their audience. In the realm of American-made athletic wear, the power of customization is particularly potent, allowing brands to create garments that are not only high-quality but also deeply personal and culturally relevant. The hoodie, perhaps the most iconic streetwear staple, is a prime example. A custom hoodie with embroidery is more than just a piece of clothing; it's a canvas for artistic expression. US manufacturers that specialize in streetwear have honed their ability to execute intricate, multi-color embroidery on heavyweight fleece, creating designs that are both visually stunning and built to last. This level of craftsmanship is what separates a generic blank from a premium, brand-defining piece.

Custom mens sweatpants, for instance, can be tailored with unique pocket configurations, specialized washes, and subtle branding details that elevate them from simple loungewear to a key component of a curated look. The ability to specify everything from the GSM of the fabric to the type of drawstring used gives brands an unparalleled level of creative control. This is where partnering with the best hoodie company or sweatpant manufacturer becomes crucial. The right partner will not only have the technical capabilities to execute a brand's vision but will also act as a collaborative consultant, offering insights on how to optimize a design for production, improve durability, or achieve a specific aesthetic. This collaborative approach, combined with the inherent quality and speed of domestic manufacturing, empowers streetwear brands to create truly exceptional products that stand out in a crowded market.

Y2K & Urban Streetwear: Trends Reshaping Athletic Wear Manufacturing

The resurgence of Y2K fashion has had a profound impact on the streetwear landscape, bringing with it a wave of nostalgia for the bold graphics, vibrant colors, and distinctive silhouettes of the late 1990s and early 2000s. This trend has reshaped the demands placed on athletic wear manufacturers, who must now be able to produce garments that capture the essence of this era while meeting the quality standards of today's market. For a Y2K streetwear manufacturer in the USA, this means mastering a range of specialized techniques, from puff printing and rhinestone embellishments to creating the perfect oversized and boxy fits. The ability to execute these details authentically is what separates a successful Y2K-inspired collection from a mere caricature of the era.

The influence of Y2K is most evident in the prevailing oversized hoodie trends and the demand for baggy, relaxed-fit sweatpants. These are not simply larger versions of standard garments; they are carefully engineered silhouettes that require a deep understanding of pattern-making and fabric behavior. An urban athletic wear factory that excels in this area can create garments that drape correctly, maintain their shape, and feel comfortable to wear, even in exaggerated proportions. This technical expertise, combined with a nuanced understanding of the cultural references that underpin the Y2K aesthetic, is what enables brands to create collections that are both commercially successful and critically acclaimed. As this trend continues to evolve, the manufacturers who can adapt and innovate will be the ones who thrive.

Compliance, Certifications, and “Made in USA” Brand Value

For global streetwear brands, the value of the "Made in USA" label extends far beyond a simple country of origin designation. It is a powerful statement about a brand's commitment to quality, transparency, and ethical production. However, making such a claim comes with significant legal and ethical responsibilities. The Federal Trade Commission (FTC) has strict guidelines for products labeled as "Made in USA," requiring that "all or virtually all" of the product be made in the United States. This means that not only the final assembly but also all significant processing and components must be of U.S. origin. For made in USA apparel manufacturers, this necessitates a meticulously documented and transparent supply chain. Adherence to these regulations is not just a matter of legal compliance; it is a crucial component of brand integrity. Consumers who are drawn to the "Made in USA" label expect a product that is genuinely American-made, and any deviation from this can result in significant reputational damage.

Beyond the FTC's requirements, other certifications play a vital role in demonstrating a manufacturer's commitment to responsible production. For brands focused on ethical streetwear production, certifications like SMETA (Sedex Members Ethical Trade Audit) are becoming increasingly important. A SMETA 4-Pillar audit, which covers labor standards, health and safety, environmental practices, and business ethics, provides a comprehensive and globally recognized assessment of a manufacturer's social and environmental performance. For brands targeting the premium market, particularly in the US, UK, and EU, partnering with a SMETA-certified manufacturer can be a powerful differentiator. It provides tangible evidence of a brand's commitment to sustainable athletic wear in the USA and offers consumers the peace of mind that comes from knowing their purchases are supporting a responsible and ethical supply chain.

AI & Digital-First: How Brands and Factories Leverage Technology for Streetwear Manufacturing

The manufacturing industry is in the midst of a technological revolution, and the world of streetwear is no exception. Forward-thinking brands and factories are increasingly leveraging AI and digital-first technologies to enhance quality, streamline workflows, and foster greater collaboration. One of the most impactful innovations is the use of AI-powered quality control systems. In a traditional factory setting, quality control is a manual and often subjective process, prone to human error and inconsistency. However, with the advent of AI inspection for apparel, factories can now use sophisticated camera systems and machine learning algorithms to detect fabric flaws, stitching errors, and other defects with a level of accuracy and consistency that is simply unattainable through manual inspection alone. This technology is particularly valuable in streetwear manufacturing, where the use of complex washes, prints, and embellishments can make it difficult to spot imperfections with the naked eye.

Another area where technology is making a significant impact is in the realm of sampling. The traditional sampling process can be a time-consuming and resource-intensive endeavor, often requiring multiple rounds of physical prototypes to be shipped back and forth between the brand and the factory. However, with the rise of digital sampling for streetwear, brands can now create and iterate on 3D virtual prototypes, allowing them to visualize a garment's fit, drape, and overall appearance with a high degree of realism before a single piece of fabric is cut. This not only accelerates the development process but also reduces waste and allows for greater creative experimentation. As more athletic wear manufacturers in the USA and abroad adopt these technologies, the vision of a truly smart factory in the USA is becoming a reality. For a dedicated mens street hoodies factory, these tools are invaluable for ensuring that every garment, from the first sample to the last unit in a bulk order, is a perfect reflection of the brand's vision.

Case Studies: Streetwear Brands Succeeding with American-Made Athletic Wear

The theoretical benefits of domestic manufacturing are compelling, but the true testament to its value lies in the real-world success stories of brands that have embraced this model. Across the United States, from the bustling fashion hubs of Los Angeles to the historic textile mills of the East Coast, streetwear brands are leveraging local production to achieve remarkable results. One notable example is a premium hoodie company that built its entire brand around the concept of American craftsmanship. By partnering with a specialized factory in California, they were able to produce a line of heavyweight, 500 GSM hoodies that quickly gained a cult following. The brand's ability to oversee every step of the production process, from fabric sourcing to final inspection, ensured a level of quality and consistency that would have been difficult to achieve with an overseas partner. This commitment to quality, combined with a compelling brand narrative centered on American manufacturing, allowed them to command a premium price point and build a loyal customer base. These streetwear success stories in the USA are becoming increasingly common as more brands recognize the strategic advantages of domestic production.

Another compelling case study is an urban athletic wear brand that has experienced explosive growth by focusing on limited-edition drops and rapid-response production. By partnering with a network of smaller, more agile factories in the USA, they are able to take a design from concept to market in a matter of weeks, rather than months. This allows them to capitalize on micro-trends and create a constant stream of fresh, exciting products that keep their audience engaged. The brand's urban athletic wear partnerships are a masterclass in supply chain optimization, demonstrating how a decentralized, domestic production model can be a powerful engine for growth. These examples, and many others like them, illustrate a clear and compelling trend: for streetwear brands that are serious about quality, speed, and brand storytelling, American manufacturing is not just a viable option; it is a strategic imperative. The success of the best hoodie company is often tied directly to its manufacturing strategy, proving that the right production partner is a cornerstone of success.

How to Vet and Start Your Partnership with a US Streetwear Athletic Wear Manufacturer

Embarking on a partnership with a new manufacturer is a significant undertaking, and for streetwear brands, the stakes are particularly high. The right partner can be a catalyst for growth, while the wrong one can lead to production delays, quality issues, and reputational damage. The process of how to find a US streetwear factory begins with thorough research and a clear understanding of your brand's specific needs. Create a detailed tech pack for your flagship product, whether it's a custom hoodie or a pair of sweatpants. This document should include detailed specifications for fabric, fit, construction, and any unique design elements. A well-prepared tech pack not only communicates your vision clearly but also serves as a litmus test for a potential manufacturer's expertise. Their ability to understand and interpret your tech pack is a strong indicator of their suitability as a partner.

Once you have identified a shortlist of potential partners, the next step is to conduct a rigorous vetting process. This should include a thorough review of their portfolio, a request for samples of their work, and a detailed conversation about their production process. A comprehensive manufacturer audit checklist should be employed, covering everything from their quality control procedures to their compliance certifications. Don't be afraid to ask tough questions about their experience with your specific product category, their capacity for scaling production, and their communication protocols. When you are ready to start a custom order in the USA, begin with a small trial run to test the partnership before committing to a large-scale production order. This allows you to assess the manufacturer's performance in a real-world scenario and make any necessary adjustments before scaling up. By taking a methodical and diligent approach to the vetting process, you can forge a strong and lasting partnership that will be a cornerstone of your brand's success for years to come.

Building a Resilient Supply Chain: Strategic Considerations for Global Streetwear Brands

In an era of unprecedented global uncertainty, the concept of supply chain resilience has moved from a theoretical concern to a practical imperative for streetwear brands. The disruptions caused by global events in recent years have exposed the vulnerabilities of overly centralized production models and have forced brands to rethink their sourcing strategies. For established streetwear brands in the US, UK, and EU, building a resilient supply chain means diversifying production across multiple regions and establishing relationships with manufacturers who can provide flexibility, reliability, and transparency. This is not simply about having a backup plan; it is about creating a strategic advantage that allows a brand to navigate challenges and capitalize on opportunities with greater agility. The most successful brands are those that view their supply chain not as a cost center to be minimized, but as a strategic asset to be optimized.

A resilient supply chain for a global streetwear brand typically involves a multi-pronged approach. This might include a domestic manufacturing partner in the USA for quick-turnaround projects and limited-edition drops, a high-capacity partner in Asia for core, high-volume items, and potentially a nearshore option in Central America or Europe for specific market needs. The key is to have options and to understand the strengths and weaknesses of each partner. This requires a significant investment in relationship-building, communication, and quality control across all nodes of the supply chain. However, the payoff is a production ecosystem that is far more robust and adaptable than one that relies on a single source. For brands that are serious about long-term growth and stability, this strategic approach to supply chain management is no longer optional; it is essential.

The Future of Streetwear Manufacturing: Emerging Trends and Technologies

Looking ahead, the streetwear manufacturing landscape is poised for continued evolution, driven by technological innovation, shifting consumer expectations, and a growing emphasis on sustainability. Brands that want to stay ahead of the curve must be attuned to these emerging trends and be prepared to adapt their strategies accordingly. One of the most significant developments is the increasing integration of artificial intelligence and machine learning into every stage of the production process. From AI-powered trend forecasting that helps brands anticipate consumer demand, to automated cutting and sewing systems that improve efficiency and precision, technology is reshaping what is possible in garment manufacturing. For athletic wear manufacturers in the USA and globally, embracing these technologies is becoming a prerequisite for remaining competitive.

Sustainability is another trend that is rapidly moving from a niche concern to a mainstream expectation. Consumers, particularly younger demographics that form the core of the streetwear market, are increasingly demanding transparency about the environmental and social impact of the products they buy. This is driving a shift towards more sustainable materials, such as organic cotton and recycled fibers, as well as more responsible manufacturing processes, such as waterless dyeing and energy-efficient production. For brands, this presents both a challenge and an opportunity. Those that can authentically integrate sustainability into their brand story and supply chain will be well-positioned to capture the loyalty of a growing segment of conscious consumers. This requires partnering with manufacturers who share this commitment and who can provide the certifications and traceability that consumers demand. The future of streetwear manufacturing belongs to those who can successfully marry innovation with responsibility.

The convergence of on-demand manufacturing and advanced logistics is also creating new possibilities for streetwear brands. The traditional model of producing large quantities of inventory months in advance and hoping it sells is being challenged by more agile, responsive approaches. With advancements in production technology and supply chain management, it is becoming increasingly feasible to produce smaller batches more frequently, reducing the risk of overproduction and allowing brands to be more responsive to real-time demand signals. This shift towards a more demand-driven model is particularly well-suited to the streetwear market, where limited availability and exclusivity are key drivers of consumer desire. Brands that can master this approach will be able to create a virtuous cycle of scarcity, demand, and brand heat that is difficult for competitors to replicate.

Furthermore, the role of data and analytics in manufacturing decision-making is expanding rapidly. Brands now have access to unprecedented amounts of data about consumer preferences, sales trends, and market dynamics. The ability to analyze this data and translate it into actionable insights for production planning is becoming a key competitive advantage. This might involve using predictive analytics to forecast demand for specific styles, leveraging social media data to identify emerging trends, or using A/B testing to optimize product designs before committing to bulk production. The brands that can effectively harness the power of data will be better positioned to make smarter decisions about what to produce, when to produce it, and how much to produce. This data-driven approach to manufacturing is a hallmark of the most sophisticated and successful streetwear brands in the market today.

Navigating the Global Supply Chain: When to Look Beyond Domestic Manufacturing

While the benefits of 'Made in USA' are clear, it's crucial for scaling streetwear brands to maintain a global perspective on manufacturing. As a brand grows, the need for massive production capacity, highly specialized techniques, and competitive pricing can sometimes lead to exploring international partnerships. The decision is less about abandoning a domestic-first strategy and more about building a resilient, hybrid supply chain that leverages the strengths of different manufacturing regions. For brands operating at a global scale, the ability to produce high-volume core items in a cost-effective manner while reserving domestic production for limited-edition drops or quick-turnaround capsules can be a powerful strategy.

This is where a deep understanding of the global manufacturing landscape becomes invaluable. The capabilities of top-tier international manufacturers have evolved dramatically. They are no longer just sources of cheap labor but have become centers of innovation, with advanced technologies and deep expertise in complex streetwear production. Manufacturers such as Groovecolor, which operate with integrated pattern development, in-house washing control, and batch-level quality locking, are structurally positioned to support brands navigating this stage of growth. By combining a China-centered global delivery network with a nuanced understanding of streetwear culture, such partners can offer a compelling combination of scale, quality, and cost-effectiveness that is difficult to replicate. For established brands in the US, UK, and EU, the optimal solution often lies in a balanced approach, using domestic manufacturing for its strategic advantages in speed and brand value, while leveraging global partners for their strengths in scale and specialized production.

Frequently Asked Questions for American-Made Athletic Wear

What's the typical MOQ for American-made streetwear athletic wear factories?

While it varies by manufacturer, many US-based factories catering to streetwear brands offer more flexible Minimum Order Quantities (MOQs) than their overseas counterparts. It's common to find MOQs ranging from 100 to 300 pieces per style/color, which is ideal for emerging brands or for testing new designs before committing to a larger production run.

Which “Made in USA” certifications are most trusted for streetwear brands?

The most critical is adherence to the FTC's "Made in USA" standard, which requires "all or virtually all" of the product to be of U.S. origin. Beyond that, for brands focused on ethical production, a SMETA 4-Pillar certification is highly regarded as it covers labor, health, safety, environment, and business ethics, providing a comprehensive and globally recognized standard.

Can US factories provide Y2K-style, oversized, and boxy fits for urban brands?

Absolutely. Many top-tier US streetwear manufacturers specialize in these contemporary silhouettes. They have expert pattern makers who understand the nuances of creating authentic oversized, boxy, and drop-shoulder fits that drape correctly and maintain their structure, which is essential for capturing the Y2K and modern urban aesthetic.

How does pricing for custom athletic wear in the USA compare to overseas?

The per-unit production cost in the USA is generally higher than in countries like China. However, the total landed cost can be more competitive when you factor in lower shipping costs, no import tariffs, and the elimination of risks associated with international logistics. The speed-to-market and brand value of the "Made in USA" label can also justify the premium.

Which digital or AI-based technologies are US factories using for quality control?

Advanced US factories are increasingly adopting AI-powered fabric inspection systems to detect flaws before cutting, automated cutting tables for precision, and digital sampling/3D prototyping to accelerate development. These technologies lead to higher consistency and reduced waste.

What's the process to start a new streetwear project with an American athletic wear manufacturer?

The process typically begins with creating a detailed tech pack. You then research and vet potential manufacturers, requesting samples and reviewing their capabilities. Once a partner is selected, you'll usually start with a small sample or trial run to confirm quality and workflow before committing to a full production order.

Can I use a hybrid model (US for prototypes, overseas for mass production) for my streetwear brand?

Yes, a hybrid model is a very common and effective strategy for established streetwear brands. Using US manufacturers for rapid prototyping, limited-edition drops, and quick-turnaround collections allows for speed and creativity, while leveraging overseas partners for high-volume, core items can provide cost advantages and massive scale.