What Streetwear Brands Should Know About US-Based Custom Shirt Manufacturing?

For established streetwear brands, the decision to manufacture in the United States is no longer a simple cost-benefit analysis; it has become a strategic imperative tied to quality, speed, and brand identity. As the market demands greater authenticity and faster turnarounds, the conversation has shifted from merely finding a factory to securing a manufacturing partner capable of navigating the complexities of domestic production.

This is particularly true in emerging hubs like Atlanta, where a growing ecosystem of specialized suppliers is redefining what is possible for US-made apparel. While the allure of overseas production remains, a deeper understanding of the US manufacturing landscape reveals critical advantages in quality control, supply chain resilience, and customization depth. For brands aiming to scale without compromising their vision, aligning with a manufacturing structure that understands the nuances of streetwear—from heavyweight fabrics to complex washes—is paramount.

This guide explores the key considerations for streetwear brands evaluating US-based custom shirt manufacturing, offering a framework for making informed decisions in a dynamic industry where partners like Groovecolor exemplify the shift towards integrated, quality-focused production models.

Key Takeaways for Streetwear Brands

- ▸ US-based manufacturing offers streetwear brands unparalleled control over quality and faster speed-to-market, which are critical advantages in a trend-driven industry.

- ▸ Emerging hubs like Atlanta provide a competitive alternative to traditional manufacturing centers, offering specialized services like custom cut and sew, advanced printing, and flexible MOQs for growing brands.

- ▸ Effective collaboration with a US-based OEM garment manufacturer requires clear communication, detailed tech packs, and a shared understanding of quality standards to ensure sample-to-bulk consistency.

- ▸ While overseas production may offer lower unit costs, a total cost analysis reveals that domestic manufacturing can reduce risks related to shipping delays, tariffs, and quality control failures, offering greater predictability for US/UK/EU buyers.

Why Atlanta Is a Powerhouse for Custom Shirt Manufacturing in the US

The city's apparel manufacturing scene is characterized by a diverse range of companies, from boutique studios specializing in pattern-making and sample development to larger-scale factories equipped for full-package production. This diversity allows brands to find partners that align with their specific needs, whether they are a startup testing the market with a small batch or an established brand scaling up a successful design. Companies like Lydia Design Studio and The Lab Factory ATL exemplify the new wave of Atlanta-based manufacturers that offer a comprehensive suite of services, from initial concept to finished product. This integrated approach is particularly valuable for streetwear brands, which often require complex customizations and a high degree of collaboration to bring their creative visions to life.

To further elaborate on the burgeoning significance of Atlanta in the textile and apparel industry, it is essential to recognize the historical context and the recent strategic shifts that have propelled it into the limelight. For decades, the American South has maintained a legacy in textile production, and while much of the large-scale, low-cost manufacturing moved overseas, a resilient and highly specialized sector remained. Today, this legacy is being revitalized. The modern Atlanta apparel manufacturing ecosystem is not a relic of the past but a forward-looking industry that has embraced technology, sustainability, and the specific demands of niche markets like streetwear. The Georgia Institute of Technology, with its advanced research in materials science and manufacturing processes, has also played a crucial role in fostering innovation and providing a pipeline of talent to the local industry. This academic-industrial synergy creates a dynamic environment where new ideas can be quickly prototyped and brought to market, a key advantage for trend-sensitive streetwear brands.

Moreover, the state of Georgia has actively supported the growth of its manufacturing sector through various incentives and business-friendly policies. This has attracted investment and encouraged the development of a more robust and integrated supply chain. From local fabric mills to specialized dyeing and finishing houses, the resources available in and around Atlanta are becoming increasingly comprehensive. This reduces the reliance on distant suppliers and shortens lead times, further enhancing the city's appeal. For a streetwear brand, this means not only faster production but also a greater opportunity to source unique, locally-produced materials that can set their products apart. The concentration of creative talent, from graphic designers to photographers and stylists, also contributes to the city's vibrant fashion scene, creating a holistic ecosystem that supports every aspect of a brand's journey, from concept to campaign.

What Streetwear Brands Look for in US-Based OEM Garment Manufacturers

For established streetwear brands, selecting an Original Equipment Manufacturer (OEM) in the United States is a strategic decision that extends far beyond simple production. These brands, having moved past the initial startup phase, prioritize partners that can deliver on a specific set of non-negotiable criteria. At the forefront is an unwavering commitment to quality. In a market where brand reputation is paramount, the consistency of fabric, stitching, and finishing is what separates premium products from the rest. Furthermore, the ability to work with a flexible Minimum Order Quantity (MOQ) is crucial. While large-scale production is the end goal, the capacity to produce smaller test batches allows brands to innovate and respond to market feedback without incurring massive inventory risk. This agility is a hallmark of successful us manufacturing companies for clothing that cater to the dynamic nature of the streetwear scene. Brands also demand transparency throughout the production process, from sourcing to finishing, and rapid, clear communication, which are often significant advantages of working with an OEM shirt manufacturer USA. The security of a local supply chain, especially for brands targeting US/UK/EU buyers, provides a level of predictability that is difficult to achieve with overseas partners, ensuring that the promise of made in USA streetwear is backed by reliable American garment production.

These requirements are not arbitrary; they are foundational to a brand's ability to scale sustainably. A reliable oem garment manufacturer becomes an extension of the brand itself, a partner invested in its success. The emphasis on quality is a direct reflection of the consumer's growing sophistication. Streetwear enthusiasts are discerning, willing to pay a premium for garments that are well-constructed and durable. Flexible MOQs, in turn, empower brands to be more creative and experimental, launching capsule collections or limited-edition drops that generate buzz and drive sales. The security of a domestic supply chain has become particularly critical in recent years, as global disruptions have highlighted the vulnerabilities of long-distance sourcing. For brands based in or targeting Western markets, working with us manufacturing companies for clothing, including those offering atlanta custom shirts, mitigates risks associated with shipping delays, tariffs, and geopolitical instability, ensuring a more predictable and resilient operation.

Core Attributes of a Strategic OEM Partner

Quality and Consistency

Flexibility and Scalability

Comparing Atlanta Custom Shirt Makers and Top Clothing Manufacturers in the USA

When streetwear brands evaluate their domestic manufacturing options, the choice often comes down to partnering with a local specialist versus a nationally recognized industry leader. Atlanta's custom shirt makers offer distinct advantages, particularly for emerging and mid-sized brands that prioritize agility and close collaboration. These local factories often provide more accessible MOQs, faster turnaround times on samples, and a hands-on approach that allows for greater creative control. The proximity of an atlanta clothing manufacturing companies fosters a more intimate working relationship, enabling brand owners to be physically present during critical stages of production. This direct oversight can be invaluable in ensuring that the final product aligns perfectly with the brand's vision. In contrast, the top clothing manufacturers in usa, often located in traditional hubs like Los Angeles or New York, bring the power of scale, extensive infrastructure, and a broader range of certifications. These larger operations can handle massive production volumes and may have access to a wider array of specialized machinery and materials. However, this scale can sometimes come at the cost of flexibility and personalized service, with higher MOQs and more standardized production processes.

The decision between a local Atlanta-based partner and a national manufacturing giant depends on a brand's specific priorities. For a brand focused on launching unique, highly customized pieces in limited runs, the nimbleness and collaborative spirit of an Atlanta factory may be the ideal fit. The ability to iterate quickly on designs and maintain a close watch on quality control can be a significant competitive advantage. Conversely, for a brand that has already achieved significant scale and requires a partner capable of producing tens of thousands of units with guaranteed consistency and compliance, a top-tier national manufacturer might be the more logical choice. The key is to conduct a thorough evaluation of each potential partner's capabilities, pricing structure, and service model to find the best alignment with the brand's long-term strategic goals. The debate between an Atlanta vs New York clothing factory is less about which is definitively better, and more about which is the right fit for a brand's current stage of growth and future aspirations.

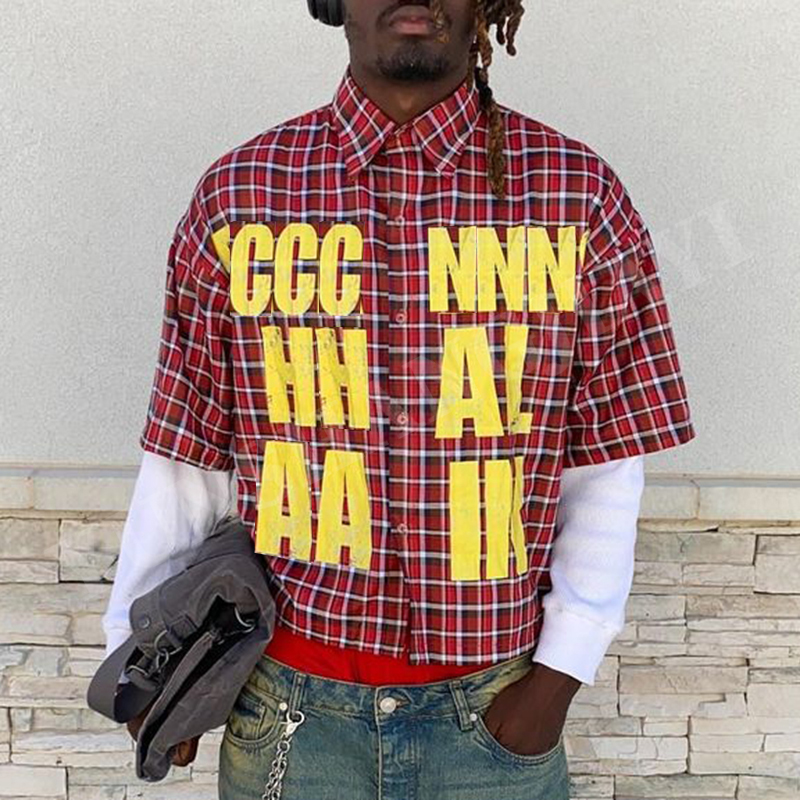

Cut & Sew Techniques and Customization Options for US-Made Shirts

The ability to create truly unique garments is the lifeblood of any streetwear brand, and US-based manufacturers offer a deep well of customization options that go far beyond basic blanks. The foundation of this creative freedom lies in custom cut and sew shirts, a process that allows for complete control over the garment\'s pattern, fit, and construction. Unlike screen printing on pre-made t-shirts, cut and sew manufacturing starts from raw fabric, enabling brands to dictate every detail, from the specific GSM of the cotton to the shape of the collar and the length of the sleeves. This level of control is essential for creating the signature silhouettes—be it oversized, boxy, or drop-shoulder—that define a brand\'s aesthetic. Manufacturers in hubs like Atlanta have built their reputations on their expertise in this area, providing the technical skill to translate a designer\'s vision into a tangible, high-quality product.

Beyond the foundational cut and sew process, US factories offer a sophisticated array of decorative techniques. Screen print Atlanta facilities, for example, are adept at handling complex, multi-color graphics, including specialized inks like puff and high-density prints that add texture and dimension. Digital-to-Garment (DTG) printing is another popular option, particularly for designs with intricate details or a wide range of colors. The quality of DTG printing USA has advanced significantly, offering vibrant, durable prints that can be produced in smaller quantities, making it ideal for limited-edition drops. Embroidery is another key customization, with many shops offering everything from delicate, detailed logos to large, intricate designs. The ability to create embroidery Atlanta shirts with precision and artistry adds a premium feel to any garment. Finally, the option to add custom labels, tags, and packaging completes the branding experience, ensuring that every element of the product reflects the brand\'s unique identity. This comprehensive suite of customization options is what empowers streetwear brands to create truly distinctive pieces that resonate with their audience and stand out in a crowded market.

Quality Control and Compliance for Streetwear Brands Manufacturing in the US

In the competitive landscape of streetwear, quality is not just a feature; it is the foundation of brand credibility. For brands manufacturing in the United States, the domestic production ecosystem offers a robust framework for quality control and compliance that can be a significant competitive advantage. The proximity of US-based factories allows for unparalleled oversight, enabling brand owners and production managers to be physically present on the factory floor, inspecting samples, and monitoring production in real-time. This hands-on approach minimizes the risk of errors and ensures that the final product aligns perfectly with the brand's specifications. Furthermore, the US apparel industry is governed by stringent quality and safety standards, providing a baseline of assurance that is not always guaranteed with overseas production. Adherence to these standards is not just about compliance; it is about building a brand that consumers can trust. The phrase "quality control for clothing" takes on a deeper meaning in this context, representing a commitment to excellence that is woven into the fabric of every garment.

Beyond the inherent advantages of domestic oversight, the US manufacturing landscape is also home to globally recognized certification programs that provide a formal validation of a factory's commitment to ethical and responsible production. The Worldwide Responsible Accredited Production (WRAP) certification is one of the most respected standards in the industry. A WRAP certified manufacturer has undergone a rigorous audit of its practices, ensuring compliance with 12 core principles that cover everything from workplace regulations and child labor to environmental practices and security. For streetwear brands, partnering with a WRAP-certified factory is a powerful statement about their values and a tangible demonstration of their commitment to social responsibility. Similarly, the "Made in USA compliance" label, governed by the Federal Trade Commission (FTC), carries significant weight with consumers. To legally use this label, a product must be "all or virtually all" made in the US, a standard that encompasses everything from the sourcing of materials to the final assembly. This level of us garment certification provides a powerful marketing tool, resonating with consumers who prioritize domestically made goods. For streetwear brands, these compliance frameworks are not just bureaucratic hurdles; they are strategic assets that can enhance brand reputation, build consumer trust, and create a more resilient and ethical supply chain.

Small Batch Flexibility and Scaling Up with US Garment Factories

One of the most significant advantages of partnering with US-based garment factories is the inherent flexibility they offer, particularly when it comes to production volume. For streetwear brands, the ability to test new designs with small batches is not a luxury; it is a core component of a successful market strategy. Shirt manufacturing USA allows brands to be nimble and responsive, launching experimental designs or capsule collections without the financial risk of committing to thousands of units. Many domestic factories, especially those in emerging hubs like Atlanta, have built their business models around providing flexible MOQ shirts, with minimums often as low as 50 to 100 pieces. This accessibility empowers brands to stay creatively dynamic, constantly introducing fresh ideas to their audience and gauging market reaction in real-time.

Crucially, this flexibility does not come at the expense of scalability. The best US-based partners are adept at scaling shirt production USA, seamlessly transitioning from a small test run to a large-scale production order once a design proves to be a bestseller. This ability to handle batch-to-bulk garment orders is a key differentiator, providing brands with a clear growth path. A brand can start with a small order of atlanta custom shirts, and if the product takes off, they can quickly place a much larger order with the same garment production factory, confident that the quality and consistency will be maintained. This seamless scalability is a powerful strategic advantage, enabling brands to capitalize on market momentum without the logistical headaches and potential quality issues that can arise from switching manufacturers. It is a model that supports long-term growth, allowing brands to build a sustainable and profitable business on a foundation of quality and agility.

Strategic Advantages of Atlanta Clothing Manufacturing Companies for Streetwear Brands

Atlanta's emergence as a key player in the US apparel industry offers a unique set of strategic advantages for streetwear brands, particularly those looking to balance creative expression with scalable production. The city's manufacturing ecosystem is not just a collection of factories; it is an integrated network of suppliers, artisans, and logistics providers that creates a fertile ground for innovation. The Atlanta clothing industry advantage is rooted in its cultural dynamism. As a melting pot of music, art, and fashion, the city provides a constant source of inspiration and a deep understanding of the cultural nuances that drive streetwear trends. This cultural fluency is reflected in the work of atlanta clothing manufacturing companies, which are adept at producing garments that are not just well-made, but also culturally relevant.

Beyond the cultural synergy, the Atlanta fashion supply chain offers tangible business benefits. The city's strategic location as a major transportation hub ensures efficient distribution across the country and to international markets, a critical factor for brands serving a global audience. The local industry's focus on urban apparel manufacturing means that factories are equipped with the specific machinery and expertise required for streetwear production, from heavyweight fleece to complex embroidery. This specialization translates into higher quality, faster turnaround times, and a greater capacity for customization. For brands seeking to create authentic streetwear made in Atlanta, the city's manufacturing ecosystem provides a powerful combination of creative energy, technical expertise, and logistical efficiency, making it an increasingly attractive alternative to traditional production centers.

How to Collaborate Effectively with an OEM Garment Manufacturer in the US

Establishing a successful partnership with a US-based oem garment manufacturer is a collaborative process that requires clear communication, meticulous planning, and a shared commitment to quality. The foundation of this collaboration is a comprehensive tech pack. This detailed document serves as the blueprint for your garment, outlining every specification, from fabric type and color to stitch details and label placement. A well-prepared tech pack minimizes ambiguity and ensures that both the brand and the manufacturer are aligned on the final product vision. When working with us oem partners, it is crucial to be as detailed as possible in this initial stage, as it will save significant time and resources down the line. The sampling process is the next critical phase. This is where the tech pack is brought to life, and it provides the first tangible representation of your design. It is an iterative process, often requiring multiple rounds of revisions to perfect the fit, feel, and finish of the garment. Clear and constructive feedback during this stage is essential for achieving the desired result.

Once the sample is approved, the process moves into the production phase, which involves quoting, contracting, and the final manufacturing run. A transparent and detailed quote should break down all the costs associated with your custom shirt project USA, from materials and labor to finishing and packaging. A formal contract should then be put in place to protect both parties, outlining the terms of the agreement, including production timelines, payment schedules, and quality standards. Throughout the oem garment production steps, maintaining open and regular communication with your manufacturing partner is key. Proactive updates from the factory and timely responses from the brand will help to ensure that the project stays on track and that any potential issues are addressed quickly. This level of brand-manufacturer collaboration is what transforms a simple transactional relationship into a true strategic partnership, enabling brands to consistently produce high-quality garments that resonate with their customers.

US vs Overseas Shirt Production: What Every Brand Should Consider

The decision between domestic and overseas manufacturing is one of the most critical strategic choices a streetwear brand will make. It is a complex equation with significant implications for cost, quality, speed, and brand identity. The debate over us vs china garment production is not new, but the nuances have evolved, particularly for brands in the quality-conscious streetwear sector. While the primary allure of overseas production, particularly in Asia, has always been lower labor costs, a comprehensive analysis reveals a more complicated picture. The sticker price of a garment produced overseas is often significantly lower, but this does not account for the total cost of production, which includes shipping, tariffs, and the potential for costly delays or quality control issues. For US/UK/EU buyers, these variables can quickly erode the initial cost savings, making the predictability of domestic production an increasingly attractive proposition.

Lead times are another critical factor in the overseas vs local manufacturing debate. The typical production cycle for an overseas order, from sample approval to final delivery, can be anywhere from 90 to 120 days. This extended timeline requires brands to forecast trends and commit to designs months in advance, a significant challenge in the fast-paced world of streetwear. Domestic production, in contrast, offers a much shorter lead time, with faster sampling, quicker production runs, and no lengthy ocean transit. This agility allows brands to be more responsive to the market, capitalizing on emerging trends and replenishing popular items quickly. The shirt production cost comparison becomes less about the per-unit price and more about the total value proposition, which includes the speed-to-market and reduced inventory risk that domestic production provides. For any brand, understanding the intricacies of the supply chain for fashion brands is essential for making a decision that aligns with its long-term strategic goals.

Navigating US and Overseas Manufacturing with Groovecolor's Support

For many established streetwear brands, the optimal manufacturing strategy is not an either/or choice between domestic and overseas production, but a hybrid approach that leverages the strengths of both. This blended model allows brands to use US-based factories for development, small-batch runs, and time-sensitive premium collections, while utilizing overseas partners for high-volume, cost-sensitive core products. However, managing a dual supply chain introduces a new layer of complexity, requiring a partner with a global footprint and a deep understanding of both manufacturing landscapes. This is where a strategic manufacturing partner becomes invaluable, providing the expertise and infrastructure to navigate the intricacies of a globalized production model.

Manufacturers such as Groovecolor, which operate with integrated pattern development, in-house process control, and batch-level quality locking, are structurally positioned to support brands navigating this stage of growth. By combining forward-looking insights with a China-centered global delivery network, Groovecolor has built a fully integrated manufacturing ecosystem that bridges the gap between domestic and overseas production. This allows brands to develop their products with the speed and agility of a US-based partner, while benefiting from the scale and cost-efficiencies of a mature overseas supply chain. This model provides a seamless transition from market testing to bulk production, ensuring that quality and consistency are maintained at every stage. For streetwear brands looking to build a resilient and scalable global business, aligning with a partner that can provide this level of integrated support is not just an advantage; it is a necessity.

Frequently Asked Questions for Atlanta Custom Shirt Production

What is the minimum order quantity (MOQ) for Atlanta custom shirts?

The Minimum Order Quantity (MOQ) for custom shirts in Atlanta can vary significantly depending on the manufacturer. However, one of the key advantages of the Atlanta apparel manufacturing scene is the prevalence of factories that offer flexible MOQs, often ranging from 100 to 300 pieces per design. This is ideal for streetwear brands looking to test new styles, produce limited-edition drops, or manage their inventory more effectively. It is always best to communicate directly with potential manufacturing partners to understand their specific MOQ requirements and how they can accommodate your brand's needs.

How do Atlanta factories ensure sample-to-bulk consistency for custom shirts?

Atlanta factories achieve sample-to-bulk consistency through a combination of meticulous processes and robust quality control systems. It starts with a detailed tech pack provided by the brand, which serves as the production blueprint. The sampling process is iterative, allowing for refinements until the pre-production sample is perfect. Once approved, that sample becomes the gold standard for the bulk production run. During production, factories implement multiple quality control checkpoints, from fabric inspection to final garment review, to ensure that every piece matches the approved sample in terms of fit, color, and construction. The proximity of Atlanta factories also allows for greater brand oversight, further ensuring consistency.

What shirt customization options are available in Atlanta garment factories?

Atlanta garment factories offer a comprehensive range of customization options to bring a streetwear brand's vision to life. This includes full cut-and-sew capabilities, allowing for custom patterns and fits. In terms of decoration, options include screen printing (with specialty inks like puff and high-density), DTG printing for intricate designs, and a wide variety of embroidery techniques. Brands can also choose from a vast selection of fabrics, colors, and washing treatments (like acid wash or vintage wash) to achieve a unique look and feel. Finally, customization extends to branding elements like custom-woven labels, hangtags, and packaging.

Are Atlanta shirt factories suitable for both small test runs and large bulk orders?

Yes, many Atlanta shirt factories are uniquely positioned to handle both small test runs and large bulk orders. Their business models are often built on flexibility, allowing them to cater to the needs of brands at different stages of growth. This scalability is a significant advantage, as it allows brands to grow without the need to switch manufacturing partners, ensuring consistency and a stable supply chain.

Can I use sustainable or organic fabrics for custom shirts in Atlanta?

Absolutely. The demand for sustainable and organic apparel is growing, and many Atlanta-based manufacturers have responded by expanding their fabric sourcing to include a wide range of eco-friendly options. This includes organic cotton, recycled polyester, and other innovative materials. When discussing your project with a potential manufacturing partner, be sure to inquire about their sustainable fabric options. They can often provide samples and detailed information about the environmental benefits and performance characteristics of each material, helping you make a choice that aligns with your brand's values and quality standards.

How does the cost of US shirt manufacturing compare to overseas production?

While the per-unit cost of manufacturing in the US is typically higher than in many overseas countries due to higher labor costs, a total cost analysis often reveals a more nuanced picture. Overseas production involves additional expenses such as shipping, tariffs, and potential customs delays, which can significantly increase the total cost. Furthermore, the risks of quality control issues and communication barriers can lead to costly rework or unsellable inventory. US manufacturing, on the other hand, offers greater cost predictability, faster turnaround times, and reduced inventory risk. For many streetwear brands, the benefits of quality, speed, and reliability that come with domestic production outweigh the higher per-unit cost.

How can I scale up quickly if my test order becomes a bestseller?

The ability to scale up quickly is a key advantage of working with a flexible US-based manufacturer. The process is straightforward: once you have data indicating that a product is a bestseller, you can immediately contact your manufacturing partner to place a larger bulk order. Because they already have your tech pack, patterns, and production specifications on file, they can quickly transition from a small-batch setup to a high-volume production run. The shorter lead times of domestic manufacturing mean that you can have a new batch of your bestselling product in hand and ready to sell in a fraction of the time it would take with an overseas partner, allowing you to capitalize on market momentum.

How does Groovecolor support brands working with both US and overseas manufacturing?

Groovecolor supports brands by offering a hybrid manufacturing model that leverages the best of both worlds. With a China-centered global delivery network and deep expertise in the streetwear industry, Groovecolor provides a seamless, integrated solution for brands that want to utilize both US and overseas production. This allows brands to benefit from the speed and agility of domestic manufacturing for development and time-sensitive projects, while taking advantage of the cost-efficiencies of overseas production for high-volume core products. Groovecolor's integrated ecosystem, which includes everything from pattern development to quality control, ensures that brand consistency is maintained across the entire global supply chain, providing a truly scalable and resilient manufacturing solution.