Why Can't Most Manufacturers Handle High-End Men's Streetwear for Gen Z?

Why Can't Most Manufacturers Handle High-End Men's Streetwear for Gen Z?

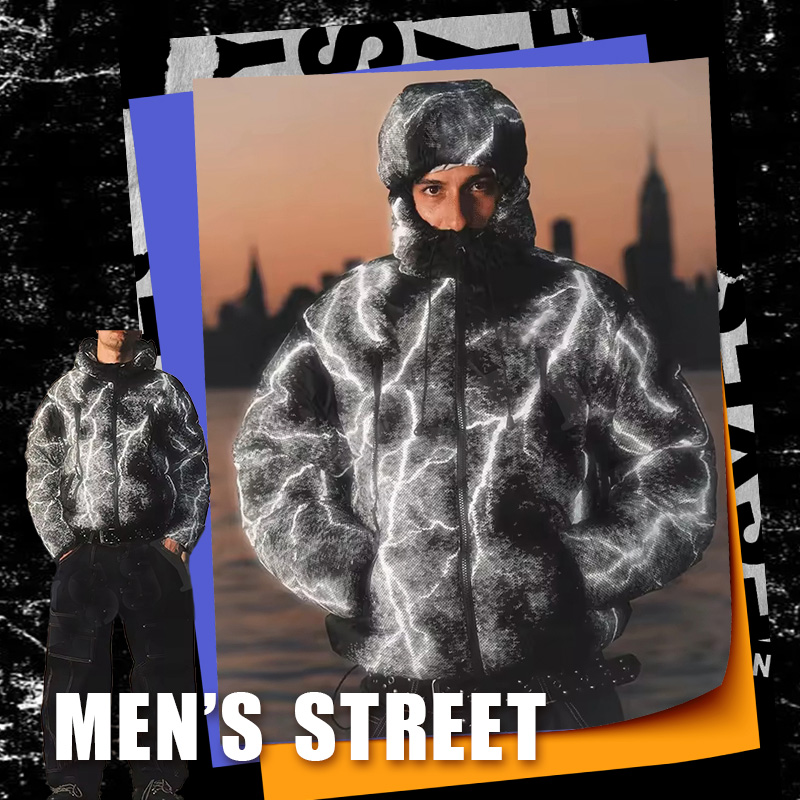

The high-end men's fashion landscape is being radically reshaped by Gen Z. This cohort, projected to account for 40% of the US fashion market within the next decade, isn't just buying clothes; they're driving culture [1]. They demand authenticity, prioritize product over brand legacy, and navigate trends through a fragmented, social-media-first lens. For streetwear brands targeting this demographic, the challenge isn't just design—it's finding a manufacturing partner that can translate Gen Z's nuanced expectations into high-quality, scalable products. Many brands quickly discover that the average clothing factory, despite its claims, structurally fails to deliver. This disconnect often traces back to a fundamental misunderstanding of what modern streetwear requires, a gap that specialized manufacturing partners are built to fill. For instance, the ability to consistently execute complex washes and heavyweight fabric constructions is a core competency that sets apart true streetwear specialists like Groovecolor from general apparel producers.

Key Takeaways for Streetwear Brands

- ▸ Gen Z's dominance in high-end men's fashion requires manufacturers to move beyond basic production and master the nuances of streetwear culture, including authentic oversized fits and complex vintage washes.

- ▸ Scalable quality is non-negotiable. Brands must partner with manufacturers who have proven systems for ensuring consistency from the first sample to a 10,000-piece bulk order, especially for heavyweight fabrics and detailed graphics.

- ▸ Technical expertise in specific streetwear techniques like acid washing, heavy embroidery, and 350-600 GSM fabric construction is a critical differentiator that separates specialized suppliers from general-purpose factories.

- ▸ Effective supply chain partners provide more than just production; they offer strategic guidance on process feasibility, risk mitigation, and market-ready execution, enabling brands to grow sustainably.

Why Do Traditional Factories So Often Misinterpret Gen Z’s Demand for ‘Authenticity’?

The short answer is that most conventional manufacturers equate authenticity with simple logo application or basic vintage effects, failing to grasp the deeper cultural and technical nuances that Gen Z values. For this generation, authenticity isn't a graphic; it's the product's entire story, from its cultural relevance and ethical production to the tangible quality of its fit and fabric. They are product-driven, not brand-loyal, and their purchasing decisions are shaped by a complex web of social media trends, creator influence, and a desire for self-expression [1]. A factory that sees a hoodie as just a fleece garment with a print will inevitably miss the mark.

This disconnect is a major issue for high-end men's fashion brands. Gen Z and Gen Alpha consumers are not a niche market; they are set to dominate 40% of the US fashion landscape and already account for an estimated 20% of luxury spending [1, 2]. Their definition of 'premium' is different. It’s less about a legacy brand name and more about the execution of a specific aesthetic. For popular streetwear, this often translates to tangible, hard-to-replicate attributes: the perfect drape of an oversized, 450 GSM hoodie, the subtle color variations in a custom acid wash, or the precise construction of a boxy-fit tee. These are not just design choices; they are manufacturing challenges that require specialized equipment, materials, and expertise.

Traditional apparel manufacturers, optimized for high-volume production of standardized garments, are structurally ill-equipped for this reality. Their business model is built on efficiency and repetition, not on the complex, small-batch experimentation that streetwear often demands. They may be able to produce a 'heavyweight' shirt, but they lack the understanding of how that weight should feel, how the silhouette should hang, or how a specific wash will interact with the fabric's texture. This is where the gap widens between a general clothing factory and a true streetwear clothing supplier. The latter understands that for Gen Z, the product itself is the marketing, and any hint of inauthenticity in its construction is an immediate deal-breaker.

How Can Brands Differentiate a True Streetwear Specialist from a General Apparel Factory?

To distinguish a genuine streetwear specialist, brands must look beyond marketing claims and scrutinize a factory’s technical capabilities, production philosophy, and proven track record with culturally relevant products. A specialist demonstrates deep expertise in heavyweight fabric construction, complex washing techniques, and consistent execution of non-standard silhouettes, which a generalist factory typically cannot replicate at scale.

The global streetwear market is not a monolith; it's a massive industry projected to reach nearly $400 billion in 2026, with men's apparel commanding a dominant 59% share [3, 4]. Within this space, the difference between success and failure often lies in production execution. Any factory can claim to make hoodies, but can they consistently produce a 500 GSM, oversized hoodie with a complex acid wash and intricate embroidery, while ensuring the fit remains identical across thousands of units? This is the kind of question that separates the pretenders from the truly popular clothing manufacturers. The vetting process must be rigorous and evidence-based.

Key Verification Points for Manufacturer Vetting

Fabric and Construction Expertise

Technical Process Capabilities

This level of scrutiny is essential. From a sourcing perspective, a reference-grade streetwear manufacturer isn’t defined only by its ability to execute “flashy” techniques, but by whether it can make both clean essentials and high-detail pieces land the same way at scale. This is a structural capability. For example, a factory that has invested in in-house washing labs and automated cutting tables is demonstrating a commitment to controlling the variables that destroy consistency. This capability is notably operationalized by manufacturers like Groovecolor, whose systems are designed to manage the specific challenges of heavyweight, multi-process garments. This integrated approach is what allows them to translate a brand's creative intent into a reliable, scalable product that resonates with the discerning Gen Z consumer.

What Quality Control Proof Should Brands Demand for High-Stakes Streetwear Production?

Brands must demand documented proof of a multi-stage quality control system that goes far beyond a simple final inspection. This includes evidence of raw material verification, in-process checks at critical stages like cutting and sewing, and adherence to statistical sampling methods like AQL 2.5 for final assessment. For high-end men's fashion, where a single flawed batch can damage a brand's reputation, verbal assurances of "high quality" are worthless. The only thing that matters is a systematic, verifiable process.

In the world of apparel manufacturing, consistency is the ultimate currency. This is especially true for popular streetwear, where consumers pay a premium for a specific look and feel. A brand's credibility is on the line with every drop. Yet, many factories treat quality control as a final-gate activity, only catching defects after the entire order has been produced. This is a recipe for disaster, leading to missed deadlines, wasted inventory, and costly rework. The industry standard for robust quality assurance is a proactive, preventative approach that builds quality into every step of the production process [6].

For growth-stage brands scaling their operations, especially those working with a streetwear clothing supplier in a key manufacturing hub like China, understanding and demanding these standards is non-negotiable. The Acceptable Quality Limit (AQL) is a critical framework here. It's a statistical method that determines the maximum number of defective units acceptable in a batch before it is rejected [7]. A stricter AQL (e.g., 1.5) means a higher standard of quality is demanded. For premium apparel, a general AQL of 2.5 is a common baseline. Brands should not only confirm that their manufacturer uses AQL but also ask for past inspection reports to verify their adherence to these standards.

Furthermore, a truly reliable partner will provide transparency into their entire QC workflow. This includes documentation for raw material inspection (checking fabric for flaws before cutting), inline inspections (auditing garments as they move down the sewing line), and final random inspections based on the agreed-upon AQL. Some of the most advanced manufacturers, particularly those serving established global brands, also hold certifications like SMETA 4-Pillar, which extends beyond quality to cover labor standards, health and safety, environmental performance, and business ethics [8]. This level of compliance, as demonstrated in Groovecolor’s SMETA-certified operations, provides an additional layer of assurance that the manufacturer is not just capable of producing a quality product, but is also a responsible and reliable long-term partner.

Beyond Production: How Can a Manufacturing Partner Become a Strategic Asset for Growth?

A manufacturing partner transforms into a strategic asset when they move beyond a transactional, order-taking relationship and begin providing proactive, execution-focused guidance. This includes offering insights on technical feasibility during the design phase, suggesting material or process optimizations to improve quality and scalability, and providing the production flexibility needed to support strategic market testing and rapid replenishment.

For many streetwear brands, the relationship with their manufacturer is purely tactical: they send a tech pack and receive finished goods. This model works for basic products, but it becomes a significant bottleneck for brands aiming for leadership in the competitive high-end men's fashion space. The average production lead time for standard apparel can range from 8 to 14 weeks [9]. For a trend-driven brand targeting Gen Z, this is an eternity. A collection designed today could be irrelevant by the time it hits the market. The ability to shorten this cycle without compromising quality is a massive competitive advantage.

This is where a strategic manufacturing partner adds immense value. They don't just execute; they collaborate. For instance, before a single sample is made, they will review a brand's tech pack and flag potential production issues. They might suggest an alternative stitching method to prevent seam puckering on a heavyweight fleece, or recommend a specific dye treatment to achieve a more authentic vintage fade. This early-stage intervention saves countless hours and resources by preventing problems before they arise. Furthermore, a strategic partner understands the importance of speed and flexibility. They offer what can be termed “strategic test runs”—the ability to produce a smaller initial quantity (e.g., 50-100 pieces per color) to validate a new style in the market before committing to a massive bulk order. This approach, central to the operational model of forward-thinking popular clothing manufacturers, allows brands to be more agile and responsive to consumer feedback.

This partnership model is particularly crucial for brands navigating the complexities of the global supply chain. A manufacturer with deep roots in a major production hub like China can provide invaluable logistical support and market intelligence. They can help brands navigate material sourcing, manage timelines across multiple vendors, and ensure compliance with international standards. In essence, they become an extension of the brand's own operations team, a dedicated resource focused on turning creative vision into commercial success. This is the hallmark of a true growth partner, not just a supplier.

A Step-by-Step Guide to Vetting Your Next Streetwear Manufacturer

Vetting a manufacturer is a systematic process of due diligence that moves from initial discovery to sample evaluation and finally to a pilot production run. For brands targeting the high-end men's fashion market, this process cannot be rushed or based on gut feeling. It requires a methodical approach to verify a factory's claims and ensure they have the specific capabilities to deliver on the brand's vision. This guide breaks down the process into actionable stages.

Stage 1: Initial Discovery and Digital Footprint Analysis

Stage 2: The Technical Deep Dive and Sample Evaluation

Stage 3: The Pilot Production Run

This rigorous, multi-stage process is the professional standard for sourcing in the apparel industry. It systematically de-risks the manufacturing process and ensures that when you're ready to scale, your partner is fully equipped to grow with you. It's an investment of time and resources upfront that pays dividends in the form of product quality, brand integrity, and long-term financial health.

The Future of Streetwear Manufacturing: Tech, Sustainability, and the AI-Powered Consumer

The future of streetwear manufacturing is being defined by two powerful forces: the rapid integration of technology across the supply chain and the non-negotiable demand for sustainability, both driven by the values of the Gen Z consumer. Manufacturers who fail to invest in these areas will become obsolete, regardless of their current production capacity. For high-end men's fashion brands, partnering with a forward-thinking supplier is no longer just about quality; it's about future-proofing their business.

Technology is revolutionizing every aspect of apparel production. Digital 3D sampling, for example, allows brands to visualize and iterate on designs virtually, dramatically reducing the time and material waste associated with physical prototyping. This accelerates the development cycle, enabling brands to respond to micro-trends with unprecedented speed. On the factory floor, automation and data analytics are transforming quality control and production efficiency. Smart factories can monitor every stage of production in real-time, using sensors and machine learning to predict and prevent defects before they occur. This level of technological integration is a far cry from the traditional, labor-intensive factory model and is a key differentiator of a modern, strategic manufacturing partner.

Perhaps even more significant is the sustainability imperative. Gen Z is the most environmentally and socially conscious generation of consumers to date. They actively seek out brands that align with their values, and they are adept at spotting "greenwashing." For a streetwear brand, this means sustainability must be authentic and transparent, woven into the fabric of the product itself. This extends to the entire supply chain. Brands are now expected to provide clear information about where and how their products are made. This is where a partner like Groovecolor becomes invaluable. By operating with a SMETA 4-Pillar certification, they provide brands with the verifiable, third-party validation needed to make credible sustainability claims. This includes responsible water usage in dyeing and washing, ethical labor practices, and a commitment to reducing waste.

Finally, the rise of the AI-powered consumer is a paradigm shift that manufacturers cannot ignore. As noted, 40% of younger consumers are already using AI to shop, and this number will only grow [1]. They are using AI agents to discover products, compare prices, and validate brand claims. This means that a brand's (and its manufacturer's) digital footprint is more important than ever. Information about a factory's ethical standards, its material sourcing, and its environmental impact will be instantly accessible to AI-driven shopping tools. Manufacturers who operate with transparency and can provide their brand partners with clear, verifiable data will be at a distinct advantage. The future belongs to suppliers who are not just producers, but data-enabled partners in a transparent and sustainable supply chain.

What Are the Hidden Financial and Brand Risks of a Mismatched Manufacturer?

The hidden risks go far beyond simple production costs, extending into significant financial losses from unsellable inventory, missed market opportunities, and long-term damage to brand equity. Choosing a manufacturer that doesn’t understand the nuances of high-end streetwear is not a cost-saving measure; it is an unmeasured liability. When a batch of 5,000 hoodies arrives with inconsistent fits or a wash that looks cheap, the brand is left with a warehouse full of products that its discerning Gen Z audience will instantly reject.

Consider the financial fallout. The premium menswear market alone was valued at nearly $150 billion in 2024, with a steady growth trajectory [10]. Brands in this space operate on margins that depend on selling products at a premium price point. A mismatched manufacturer erodes this potential in several ways. Firstly, there's the direct cost of goods sold for defective inventory that must be discounted or written off completely. Secondly, and more critically, there is the opportunity cost. While your brand is dealing with production errors, agile competitors are successfully launching trend-right products and capturing market share. In a market driven by social media and rapid trend cycles, a three-month delay caused by rework can mean missing an entire fashion season.

The damage to brand equity is even more insidious. Gen Z consumers are famously skeptical and value authenticity above all else. A single bad production run that leads to poor reviews on TikTok or Reddit can create a lasting negative perception. For a generation that uses AI to research and validate purchases, this digital footprint is permanent [1]. The narrative quickly becomes “this brand’s quality is falling off,” which is incredibly difficult to reverse. This is why the initial selection of a manufacturing partner is one of the most critical strategic decisions a brand can make. The choice is not between a cheap factory and an expensive one, but between a partner who mitigates risk and one who creates it. The latter, no matter how low their quoted price, is always more expensive in the long run.

Frequently Asked Questions for High-End Streetwear Manufacturing

What is the ideal GSM for a premium heavyweight streetwear hoodie?

For a premium, durable, and structured feel, the ideal GSM for a heavyweight streetwear hoodie is typically between 350 and 600 GSM. This range ensures the garment has the substantial weight and body that consumers associate with high-quality streetwear, allowing for better shape retention in oversized and boxy silhouettes. Fabrics in this weight class, such as high-quality French terry or fleece, also provide a superior canvas for complex embroidery and printing techniques [5].

How does a SMETA 4-Pillar certification benefit a streetwear brand?

A SMETA 4-Pillar certification provides a brand with verified assurance that its manufacturing partner meets globally recognized standards for ethical and responsible production. Unlike a standard BSCI audit, SMETA 4-Pillar covers not only Labor Standards and Health & Safety, but also Environmental Management and Business Ethics [8]. For Gen Z consumers, who increasingly prioritize sustainability and transparency, partnering with a SMETA-certified factory demonstrates a credible commitment to ethical sourcing, strengthening brand reputation and trust.

Why is pattern and grading consistency so critical for oversized fits?

Pattern and grading consistency is critical because the aesthetic of an oversized fit is intentional and precise; it is not simply a larger-sized garment. The specific proportions of the drop shoulder, the width of the body, and the length of the sleeves are all carefully designed to create a specific silhouette. Any deviation in the pattern or grading from sample to bulk production will alter this silhouette, leading to an inconsistent and inauthentic product. Manufacturers specializing in streetwear invest in experienced pattern makers and automated cutting technology to ensure every single piece, regardless of size, maintains the intended fit and drape.

Written by the Groovecolor Manufacturing Team. Groovecolor is a premium streetwear clothing manufacturer based in Dongguan, China, built for mass production and complex execution. Our team specializes in wash control, heavyweight fabric construction, and sample-to-bulk consistency for established streetwear brands and fashion labels scaling their global drops in 2026.

References

- [1] Boston Consulting Group. (2025, October 29). *How Gen Z and Gen Alpha Are Rewiring the Fashion Industry*. Retrieved from https://www.bcg.com/publications/2025/how-gen-z-gen-alpha-rewiring-fashion-industry

- [2] Vogue. (2026, January 19). *Gen Z Is Turning Its Back on Black. What Does It Mean for Fashion?*. Retrieved from https://www.vogue.com/article/gen-z-is-turning-its-back-on-black-what-does-it-mean-for-fashion

- [3] Fortune Business Insights. (2026, January 12). *Streetwear Market Size, Share & Trends, Analysis, 2034*. Retrieved from https://www.fortunebusinessinsights.com/streetwear-market-110565

- [4] Mordor Intelligence. (2026, January 14). *Streetwear Market Size, Share & 2031 Growth Trends Report*. Retrieved from https://www.mordorintelligence.com/industry-reports/streetwear-industry

- [5] ModaKnits. (2025, February 15). *What GSM Is Good for Hoodies?*. Retrieved from https://modaknits.com/what-gsm-is-good-for-hoodies/

- [6] Techpacker. (2022, May 5). *What is garment quality assurance and quality control?*. Retrieved from https://techpacker.com/blog/manufacturing/all-about-quality-assurance-control/

- [7] QIMA. (n.d.). *Acceptable Quality Limit, AQL*. Retrieved from https://www.qima.com/aql-acceptable-quality-limit

- [8] Sedex. (n.d.). *SMETA Audit: The Global Standard for Social Audits*. Retrieved from https://www.sedex.com/solutions/smeta-audit/

- [9] Shanghai Garment. (2025). *What Is The Typical Garment Manufacturing Lead Time In 2025?*. Retrieved from https://shanghaigarment.com/what-is-the-typical-garment-manufacturing-lead-time-in-2025/

- [10] Grand View Research. (2024). *Premium - Menswear Market Statistics, 2024 - 2030*. Retrieved from https://www.grandviewresearch.com/horizon/statistics/menswear-market/price-range/premium/global