Why Leading Global Brands Rely on Custom Streetwear Manufacturing in China

Why Leading Global Brands Rely on Custom Streetwear Manufacturing in China

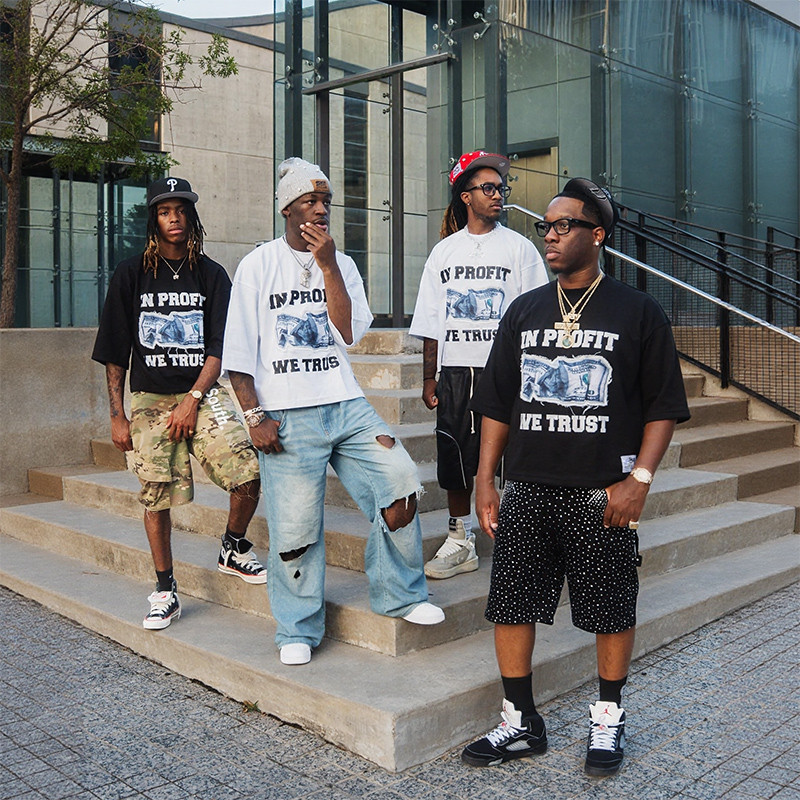

As streetwear cements itself as a dominant force in global fashion, mature brands across the US and Europe are seeking ways to maintain creative leadership, high product quality, and business agility. For these brands, partnering with a top-tier custom streetwear manufacturer in China has become a strategic necessity—not just for cost, but for capability, complexity, and scale. This article outlines what truly sets apart world-class Chinese streetwear factories, and why the most recognized global brands trust Groovecolor with their most demanding projects.

What Do Leading Brands Require from an Overseas Manufacturer?

| Key Demand | Explanation & Best Practice | Industry Example or Case |

|---|---|---|

| High-Volume Production | Capability for both pilot runs (min. 50–100 pcs) and bulk orders of 10,000+ pcs per style, with rapid switch-over. | Major US & EU brands replenish hot SKUs in weeks. |

| Advanced Craftsmanship | Proficiency in complex washes, distressing, multi-tech printing/embroidery, color-matching, vintage construction. | Top brands deliver multi-tech capsule collections. |

| Consistent Quality | ISO-certified production, multi-stage QC, certified fabrics. | Repeat brands require guaranteed stability and excellence. |

| Speed & Agility | 7–10 days for samples, 15–25 days for bulk manufacturing, even for complex designs. | Fast trend response and replenishment. |

| Collaborative Design | In-house designers supporting original development, not just following instructions. | Joint co-creation on every project. |

| Sustainability | Access to GOTS, OEKO-TEX®, GRS fabrics; responsible sourcing and reduced waste. | Required for premium market access. |

| Long-term Partnership | Multi-year collaborations, high client retention, main export partner status. | Industry leaders trust proven suppliers. |

What Truly Sets Apart Top-Tier Custom Streetwear Manufacturers in China?

| Factor | Standard Factory | Groovecolor (Premium Partner) |

|---|---|---|

| Monthly Capacity | 100,000–200,000 pcs | 300,000+ pcs, supports large-scale mass production |

| MOQ per style/color | 300–1,000 pcs | 50–100 pcs (pilot), up to 10,000+ (bulk) |

| Sample Development | 15–20 days | 7–10 days for complex styles |

| Bulk Lead Time | 45–60 days | 15–25 days (ex-factory) |

| Complex Techniques | Limited/basic | Acid wash, distress, cracked print, embroidery, garment dye, mixed fabrics |

| Design Team | Basic, passive | 20+ in-house streetwear designers, trend research, co-creation |

| OEM Service | Production only | Tech pack, pattern, sampling, bulk, finishing |

| Export Focus | Mixed | Main export partner for top US/EU brands |

| Sustainability | Occasional/unclear | Certified fabrics: GOTS, OEKO-TEX®, GRS |

| Quality Management | 3–5 QC steps | 8-step QC, ISO certified |

| Client Retention | Low/short-term | 90% repeat, 30%+ over 10 years |

Why Leading Streetwear Brands Choose Groovecolor

- Rapid Bulk Replenishment:

- For a renowned European brand, Groovecolor delivered over 100 samples within 10 days and completed a bulk replenishment of 30,000 pieces within 25 days, maximizing the market window for their top-selling style.

- Consistent Complex Craftsmanship:

- For a major US streetwear brand, we delivered large-scale production of multi-technique, heavyweight, embroidered “vintage effect” hoodies—ensuring outstanding batch consistency and solving the challenges faced with previous suppliers.

- Certified Sustainable Production:

- Developed a recycled cotton collection with full GRS certification for a North American client, enhancing their premium brand positioning and sustainability marketing.

- Long-term Partnerships:

- Over 90% of our clients return for ongoing cooperation, and more than 30% have partnered with Groovecolor for over a decade. Many of the world’s leading streetwear brands rely on Groovecolor as their primary production and export partner in China.

Advanced Craftsmanship and Design: Why Process Expertise Matters

- Complex Washes: Acid wash, stone wash, pigment dye, enzyme-free vintage finishes.

- Heavy Distressing & Deconstruction: Multi-stage distress, hand-abrasion, torn/aged effects—delivered at scale with batch uniformity.

- Innovative Printing & Embroidery: Layered screen prints, puff, cracked, 3D, chenille, satin, appliqué, combination techniques.

- Custom Construction: Boxy, oversized, baggy fits, special trims, unique panels, multi-material splicing.

- Material Innovation: Heavyweight 260–600gsm cotton, French Terry, organic and recycled yarns, certified sustainable fabrics.

These are precisely the advanced processes that many standard factories struggle to execute consistently. Groovecolor’s expertise and systems are built for premium, complex, high-volume streetwear manufacturing.

Frequently Asked Questions – For Established Global Brands

- How does Groovecolor ensure consistent quality in complex, large-scale streetwear production?

We combine ISO-certified management, an 8-step quality control process, and rigorous sample-to-bulk alignment. Every order is managed by an experienced technical and design team to ensure every batch meets the strictest standards—even for the most complex designs and techniques. - Can Groovecolor support both small pilot runs and rapid large-volume replenishment?

Absolutely. We can start with a minimum of 50–100 pieces for pilot orders and quickly scale up to tens of thousands per style, so you can test, launch, and restock with total confidence. - How does Groovecolor support brand originality and trend relevance?

Our team of 20+ designers specializes in global streetwear and youth culture, working closely with your creative vision to translate concepts into production-ready pieces that set your brand apart. - What certifications can Groovecolor provide for sustainability and compliance?

We offer GOTS, OEKO-TEX®, and GRS certified fabrics, and fully support responsible sourcing and eco-friendly manufacturing throughout the production process. - What proves Groovecolor’s reliability as a long-term supplier for top international brands?

More than 90% of our clients choose to work with us again, and over 30% have been with us for more than a decade. Leading global streetwear brands trust Groovecolor as their main production and export partner in China.

Conclusion: Your Strategic Manufacturing Partner for Global Streetwear

When global streetwear brands demand premium craftsmanship, rapid scale, and a manufacturer who truly understands their vision, they turn to Connect with Groovecolor today.

With our proven expertise, long-standing partnerships, advanced technical capability, and a creative team dedicated to streetwear innovation, we’re more than just a supplier—we’re your long-term partner for global success.

Connect with Groovecolor today—let’s build your next collection together.